Table of contents: [Hide]

- Advantages of antistatic linoleumum

- Varieties of antistatic linoleumum

- Preparatory work

- Linoleum laying technology

- List of tools and materials

Currently, antistatic coating is an indispensable thing in any home or apartment. In modern housing there are many different devices that are sources of static electricity. Computers, televisions, microwaves and other techniques have the greatest importance. To protect against the harmful effects of electrostatic electricity, antistatic linoleum is successfully used. Under normal conditions, contact with metal devices in the house may be dangerous for a person. Very often there are cases of non-link electrical discharges, and residents feel it on their own body.

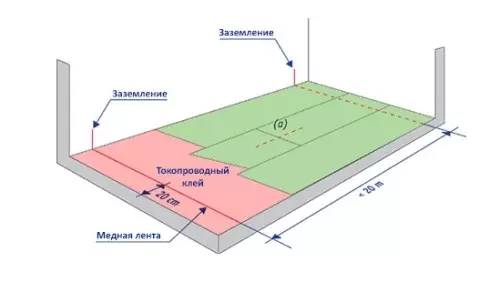

Scheme laying antistatic linoleum.

Of great importance is the fact that high levels of static electricity can adversely affect the equipment. Often there are failures in work, breakdown. In addition, static electricity contributes to the accumulation of dust, it is especially noticeable on the floor. Antistatic linoleum allows you to cope with all the above problems. Consider in more detail how to lay the antistatic linoleum, the main stages of the work, the necessary tools and materials are carried out.

Advantages of antistatic linoleumum

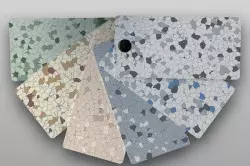

The color of the linoleum can be quite diverse.

Lining linoleum is pretty simple. What are the advantages of this material before others? Antistatic linoleum, which everyone loves, is an outdoor coating that prevents the formation and accumulation of static electricity. Simple materials when contact and friction with objects are easily electrified. This valuable linoleum from polyvinyl chloride is manufactured. The advantage of linoleum is that it is widely used both in residential buildings and in production. It refers to the positive parties the possibility of using indoors with high-precision equipment.

In this case, it is practically not replaced. It is also important that the antistatic linoleum is a reliable and safe material that can serve for many years. It is resistant to mechanical exposure, that is, there is no problems when cleaning and washing. Laying antistatic linoleum is good and the fact that it is created excellent sound insulation.

The advantage of the floor covering from PVC is high temperature resistance.

Thanks to this property, it is less dangerous in the fireplace. According to the degree of durability, it is not inferior to tile and mramor.

Antistatic linoleum is widely used in rooms with high-voltage equipment.

Modern technologies for its manufacture make it possible to pick up linoleum for your home or apartment of any color and design. The technical characteristics of this floor covering include good elasticity, wear resistance. Linoleum is able to withstand the effects of acids, alkalis, oils. It does not change its form in mechanical exposure (from pressure of the legs of the chairs or table). A very big advantage of it is the possibility of flooring on the floor with electric heating.

Back to the category

Varieties of antistatic linoleumum

Linoleum can be divided into several types: antistatic, tokescreen and conductive. All of them are somewhat different. To lay linoleum, you will need to choose the material. So, the antistatic linoleum can be called PVC-based material, which has high electrical current resistance. When a person walks, no more than 2 square meters are formed on it. Such material is great for computer classes.

Due to its structure, the conductive linoleum has resistance to 1000 mega.

As for the tokescaling coating, the resistance created by them is 100-1000 mega. It differs from the previous variant in that it contains carbon particles. With their help, the generated electrical current is quickly dissipated throughout the material. This reduces the danger of material for a person. Such a coating is often used in radiographic offices. The third type is a conductive linoleum with a resistance of 10 kiloma-10 mega. It includes graphite additives that contribute to a better current assignment from the coating. This type of linoleum is used in laboratories and other premises with a large number of complex equipment.

Back to the category

Preparatory work

The technology of laying the floor covering of this type includes 2 main stages: the preparation of the base and directly laying the insulating material. To lay a linoleum, you need to carefully choose materials and prepare a coating.

The floor before laying linoleum needs to be aligned as much as possible. Of course, it is best to make a screed.

First, a certain microclimate must be maintained for normal laying in the room. The temperature should not be below 18 degrees, the optimal relative humidity is 30-60%. Before laying, sheets leave for some time in the room. Laying the coating includes material marking. To do this, with a roulette, the room is measured and the required number of sheets is determined. Linoleum can be cut with knife or scissors.

Floor base should be dry, clean and smooth. If there are defects and irregularities, it is recommended to use primer or putty. To give the base a flat surface, suitable for chairs on wheels, a putty layer is applied with a layer of 1.5-2 mm. In the event that the laying is planned for water-sensitive materials, a layer of putty is made at least 2 mm.

Back to the category

Linoleum laying technology

After preparing the ground, it is necessary to make a ground for removal of electric current. For these purposes, a special copper tape is used. Copper strips are layered parallel to the transverse joints of the insulating material. The distance from the edge of the sheets should be about 20 cm. Under the linoleum itself, there are also copper strips, they are connected to the transverse. The latter have contact with the Earth. This ensures reliable electrical insulation. To avoid after laying irregularities, it is not recommended to be bending and folding sheets. The next stage of work is the application of special glue capable of conducting a current. It is smeared with a smooth layer right on the copper strips and give to dry. It is not recommended to use contact glue that has neoprene in its composition, as this can cause discoloration of the coating.After laying the glue makes facial coating. Linoleum must be glued entirely. It is very important that there are no emptiness and airspace between it and glue. The coating is placed on the base of the floor and roll off. You can do it immediately in two directions. If you need cuts or holes, it is important not to damage the bands located under the insulating coating. From all sides of the perimeter of the room, you can make a plinth of wood. For its manufacture, you need a drill with screws or nails. Floor coating linoleum is done.

Back to the category

List of tools and materials

To lay an antistatic linoleum laying, a whole list of tools and materials will be required:

- brush;

- rag;

- primer or putty;

- Master OK;

- roulette;

- scissors or knife;

- drill;

- Screws or nails.

It also takes a special glue, linoleum sheets, copper strips to ensure a dock and grounding. Thus, the antistatic coating today is very popular and reliable. It is applied both in private houses and in production.

Such a linoleum has a number of useful properties. Laying of such an insulating material can be carried out by its own forces without the help of professionals, it is only necessary to know the main stages of the work, including to be able to properly organize the grounding system, otherwise the floor will be ineffective.

Article on the topic: How to calculate how many tiles need to be on the bathroom?