Photo

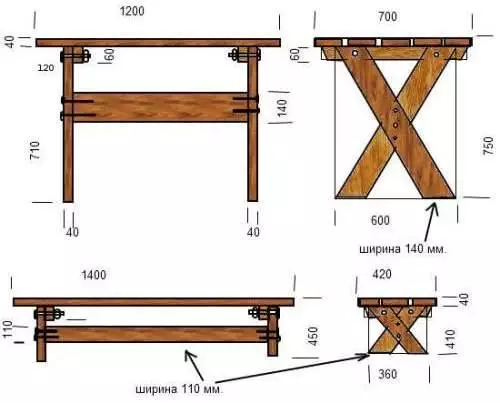

The table from the boards can be made with your own hands. For this prepare the drawing and are determined with the dimensions of the furniture. If a simple table is made, then its length (cm) should be 120, height - 75, and width - 70.

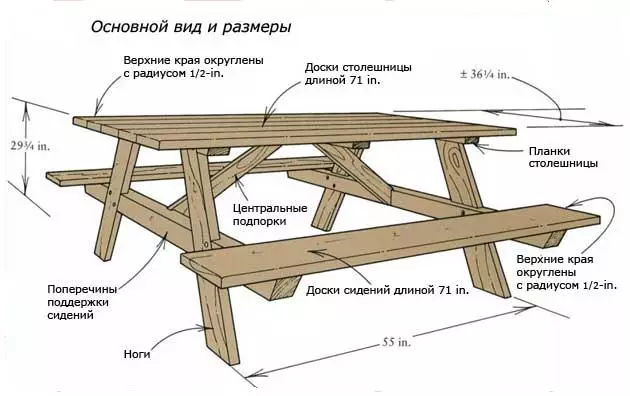

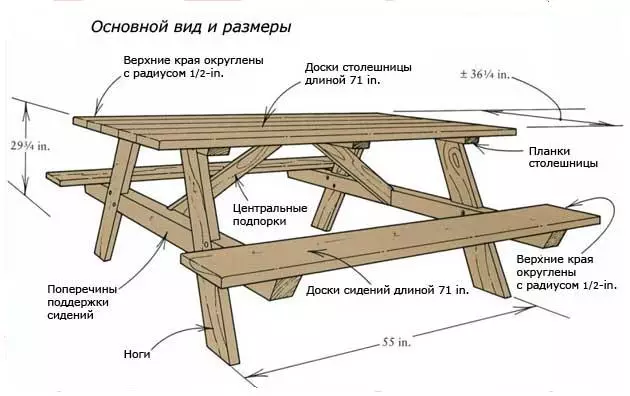

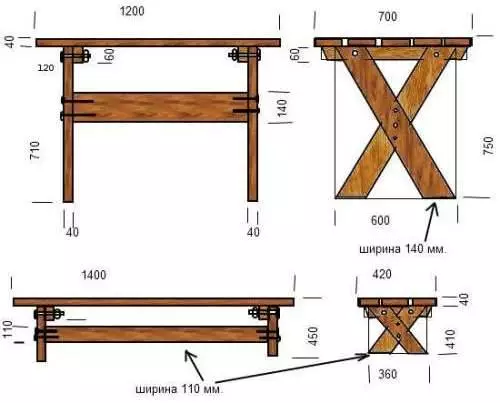

Desk pattern from boards.

Preparatory work

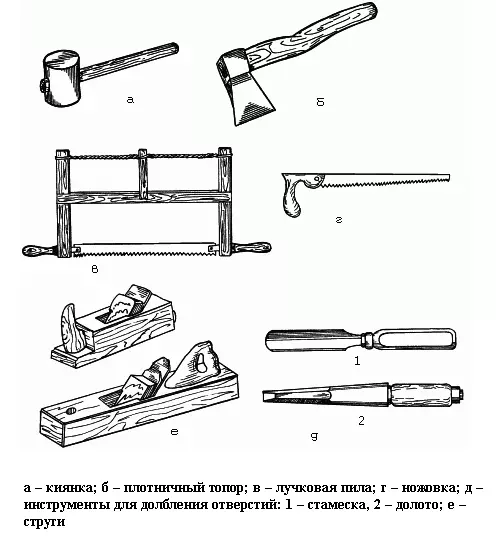

For the manufacture of furniture from the board with their own hands, the following materials will be required (mm) and tools:

- Wood 4x140;

- bars with a cross section of 40x60;

- 4 screws for 10 cm;

- Sander;

- drill;

- screwdriver.

Drawing and size of wooden table details.

Pre-doing a worktop. For this use 5 boards of the desired size. They are attached to the bars with the help of self-tales. The length of the fasteners is selected in such a way that the tree is securely fixed to the supports. To make a table from a planed usual board, you will need to equip the gap of 3-4 mm (when assembling the table top). Such technology helps when caring for furniture, preventing the mud accumulation in those places where the plank is adjacent to each other, forming the upper surface.

If the table is made with their own hands from the tongue board, then the tabletop will be presented in the form of a solid design. From the last wood, the pin (from the edge) is cleaned with a jigsaw. Future furniture is processed. To make a table from a tree, you will need to make legs. One support 2 parts must be connected to 1/2 of the tree. Material is placed according to a specific technology. On the fiberboard or plywood drawn rectangle. Its dimensions are calculated by the formula:

AH600, where

A = 750 - b (the thickness of the table top, in mm).

The next stage provides for the placement of the line in which the tree will be cut. Then make the details of the legs. The elements are customized and collected with the help of plow and screws. To make a robust table with your own hands, you will need to correctly mount its supports. For this use furniture screws.

Article on the topic: how to pour floors in the house

The rib of stiffness is fixed between the legs with long self-draws. The ends of the countertops close the bars. For their installation, nails use. The fasteners are scored in the table with their own hands with the help of a hammer. Previously need to bite off the hats. The resulting structure is painted by a verse or varnish.

Classic option

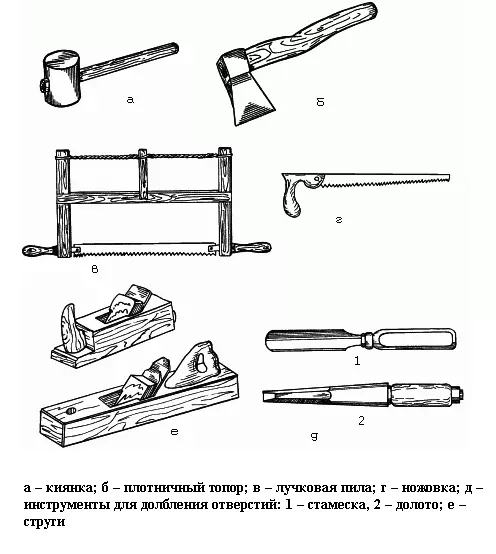

Tools for the manufacture of the table.

If you wish, you can make a classic table with your own hands. For this, you will need the following materials (cm):

- 4 BROs 10x10;

- Board 10x2;

- 4 boards 250x40 mm and 2 m long.

The production process begins with the manufacture of countertops. It gives it a rounded form. Markings are performed using a gymnastic hoop. It is placed on the boards, tightly folded in relation to each other. Wood cuts up with markup. This will require a jigsaw. Scripping of parts is made by sandpaper. The surface is grouped and covered by a verse. To assemble the design with your own hands, you will need to buy fasteners (screws 4x60).

For the manufacture of bases, wood is used (width of 800 and 1600 mm). The material from which the countertop will be equipped, laid on the floor. Top mount the resulting box. The last design needs to poison. Inner contour draw pencil. Box dismantled. From the corner of the contour make an indent of 110 mm. In the resulting points fasten the legs.

To ensure the integrity of the countertop, it will be necessary to fix the board to it (with the help of glue and galvanized screws 4x45).

The box is installed on the last element of the structure, taking into account the pre-made circuit. Details are fixed by self-drawers. The place where the feet of furniture will be mounted, leave free. The next stage provides for laying a support in the corners of the box. For their fixation, glue and self-tapping screws are used. Recent elements are screwed outside the design. To make a durable and durable table with your own hands, the leg is placed in an angle with maximum density. Furniture is ready for operation after complete drying of glue.

Article on the topic: What are the options for laying tiles on the floor