For effective removal of wax, rainwater, as well as all sorts of effluents, special systems are used, located in places with solid coatings. As elements of such systems, trays are used plastic trays together with grille. Being installed flush with the surface of the coating, the plastic channels across their entire length take the aqueous stream and remove it into the storm sewer.

Advantages of surface drainage compared to rain-seekers

The device of surface drainage involves the use of individual trays that are connected to each other. Trays are covered around the perimeter the entire surface with which water should be given. From above, the channels are closed with lattices, designed to protect the passages from the blocks wash off in them. Such systems allow safe movement in pedestrians and transport territories.

In addition to surface drainage, solid surfaces can also be equipped with point drainage systems (rain-seekers). Points of water reception are uniformly on the dried territory. They are interconnected by underground pipes that provide water removal into sewage.

The surface linear drainage of plastic trays compared to rain-seekers has the following advantages:

- Installing such a system is more beneficial from a financial point of view, since the installation of trays is easier and faster. Also required fewer materials to create drainage on the surface;

- The possibility of laying trays almost anywhere on a solid surface. The point drainage has limitations in locations due to the presence of underground communications;

- The drainage on the surface is easier to mount;

- It does not require creating external slopes towards rain-seekers. The surface remains smooth and suitable for the movement of people and transport.

- Surface trays serviced several times easier than care for a point drainage system.

Example of surface drainage with trays

Types of drainage trays, their pros and cons

All drainage trays differ in the type of material that was used for their manufacture. Each of these species has certain advantages, but not devoid of flaws.Concrete trays

The advantages of concrete products include durability, high strength, resistance to aggressive fluids, low cost and simple care for them.

As a disadvantage, a significant weight of the structures should be noted, therefore there is a need to apply lifting equipment to install them.

Article on the topic: Shelves for the balcony do it yourself

Cancer trays made of concrete

Plastic trays

These are light products, transportation and installation of which is very simple, without the involvement of special equipment. In combination with a low cost, this makes it possible to apply such trays for the arrangement of country houses, private areas with small weight loads, pedestrian zones. At the request of the customer, trays of plastic of any shape and any sizes can be made. Plastic provides high permeability and easy care.From the shortcomings, the plastic water removal tray has restrictions on weight loads.

Metal trays

Made trays of steel or cast iron. There are no special advantages in these materials, as they have a significant weight and high cost. Therefore, metal trays are rarely applied, and the metal is more often used to create channel lattices.

PolymerComposite trays

For the manufacture of such trays, a polymer concrete is used (a mixture of concrete with polymer compositions) and a polymer monitor (a mixture of polymers, sand and various additives). These materials are not inferior in all indicators of plastic products, but are more durable. Of the disadvantages there are increased fragility of channels during shock load.

Polymerbeton Cropling Tray

What is plastic trays

The rain plastic tray is made of polypropylene or low pressure polyethylene (PND). Products include mineral fillers that increase their inertia with respect to most aggressive environmental components. Such trays can be operated under all weather conditions, in the temperature range -50 + 120 degrees.

Plastic trays with almost all manufacturers are produced with a dimensional length of 1 m. Their height is within 6-79 cm, and the width varies from 9 to 50 cm.

On the photo plastic trays for water removal

What to take into account when choosing plastic trays

For the right choice of a suitable water supply suitable for a particular place, the following factors should be taken into account:- The maximum weight load that the system will experience. The calculation takes the presence of transport, heavy machinery, pedestrians. So, for industrial zones, river ports, airfields the advantage is given to concrete products. Plastic is used in places with less loads;

- The estimated amount of precipitation or effluent. According to this parameter, the bandwidth of the trays is determined (their internal section). For this, it is necessary to add another 25% to the average monthly rate of precipitation.

Tip: When choosing the elements of the system, refer to the presence of plugs in it, with which the channels are overlapped with direct angles.

Features and advantages of plastic trays

Plastic drainage trays with grille have the following advantages:

- simplicity of transportation, unloading and installation due to low weight;

- Plastic is easily processed, it cuts to the desired size and is adjusted at the place;

- Due to the smooth walls, high bandwidth trays is ensured. Mud and fat deposits are not postponed on their walls;

- resistance to most chemicals;

- Plastic is not subject to corrosion, therefore it is more durable of metal products. The service life of plastic trays is over 50 years;

- A huge variety of plastic gutters makes it possible to choose the necessary dimensions of trays for any type of drainage;

- Plastic trays are hermetically combined with each other, have technological holes for docking with sewer pipes;

- Plastic is an absolutely waterproof material, so all moisture through the channels goes into the sewer.

Article on the topic: Connecting a washing machine with your own hands

Varieties for trays

The mandatory element of any drainage channel is a grill that performs protective functions to prevent inside the system of all kinds of garbage.

Lattices differ in the following parameters:

- Load class. It is determined by the overall European qualifications, ranging from A19 and ending with F900. Thus, it is possible to perfectly pick up the desired grille for a specific type of tray;

- design. The grille is visible part of the entire channel, so its design in some cases plays a very important role when choosing. The color of the lattice is largely dependent on the material. You can meet the metallic color, black or gray tones. Colored grilles are made to order. The shape of slots differ slotted, cellular, wavy grilles, as well as made by the pigtail;

- Production material. Lattices can be made of just three materials: plastic, cast iron and steel:

Plastic trays with steel and cast-iron lattices

- Plastic products are installed in places with low loads, up to 1.5 tons. These are the places of pedestrian walkways, platforms, receiving territories.

- Steel lattices produced by the method of stamping are also not adapted for heavy loads. The plastic tray with steel grille is able to withstand the load to 1.5 tons.

- Steel welded grids withstand the load up to 12.5 tons. They are installed in places of movement of passenger transport.

- Cast iron lattices belong to high-strength elements. The drainage tray with the cast iron grille is installed in places exposed to loads more than 25 tons.

Rules Installations Tracks

Watering is a complex process requiring compliance with some rules:

- The design of the tray is selected depending on the area of its application. For example, a plastic tray is not suitable for installation in a promsion, and concrete products are unreasonable to mount in the country. The same approach should be used when choosing lattices;

- In the process of installation of the tray, it is necessary to ensure a slope of 1 cm for each directive meter of the waterway;

- Grilles must be securely fixed on the grooves to avoid their offset and clogging channels;

- The underlying sand or gravel pillow is strictly mandatory. Her presence smoothes the effect of soil bumping;

- The surface of the lattice tray must be below the solid surface by 3-5 mm.

Tip: It is recommended to install in the system sand-tractor, which will protect the channels from casing.

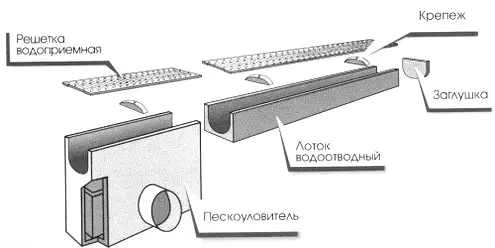

Scheme of installation of drainage trays with sands

The order of installation of plastic trays

Competent installation of plastic drainage trays is performed in several stages:

- Tretes are prepared for the necessary dimensions, taking into account the slope.

- The soil in the trenches is compacted, after which the sand or rubble layer is covered in the trench.

- It is manufactured by a concrete base that covers the bottom and walls of the trench.

- Trays are installed in the trenches and fit together through the grooves available in them. Each subsequent tray from top to bottom is inserted into the previous tray. To connect channels at an angle in one of them, the designated docking node is cut, and the plug is installed on the open space.

- All joints between trays are sealed.

- Protective grilles are installed on top of the channels.

Installation of plastic drainage trays with steel grille

Mounted for all rules, such a system will reliably protect any area from flooding.

Price

The price of the tray drainage plastic may differ depending on different parameters. The approximate cost of trays with a grid and without it is shown below.

| Name | Load class | Length, mm. | Width, mm. | Height, mm. | Weight, kg | price, rub. |

| Tray Waterproof Aqua-Top with Plastic Grid | BUT | 1 000 | 135. | 100 | 1.5 | 477. |

| Tray Waterproof Aqua-Top with galvanized grid | BUT | 1 000 | 135. | 100 | 1,8. | 522. |

| Tray Waterproof Plastic LVP Norma DN100 H55 | A, B, with | 1 000 | 148. | 55. | 1.0 | 288. |

| Tray Waterproof Plastic LVP Norma DN100 H70 | A, B, with | 1 000 | 148. | 70. | 1,2 | 324. |

| Tray Waterproof Plastic LVP Norma DN100 H120 | A, B, with | 1 000 | 148. | 120. | 1,7 | 378. |

| Set: S'Park Plastic Tray with Steel Galvanized Grid | BUT | 1000. | 90. | 90. | 0.76 | 480. |

| Set: S'Park Plastic Tray With Plastic Grid | BUT | 1000. | 90. | 90. | 0.76 | 450. |

| Set: S'Park Plastic Tray With Plastic Grid | BUT | 1000. | 135. | 70. | 1,22 | 500. |

| Polymax Basic Plastic Tray Pan | A, B, with | 1000. | 145. | 55. | 0.9 | 310. |

| Polymax Basic Plastic Tray Pan | A, B, with | 1000. | 145. | 80. | 1,1 | 370. |

| Polymax Basic Plastic Tray Pan | A, B, with | 1000. | 160. | 120. | 1.65 | 420. |

Article on the topic: Dry carbon dioxide: testimony and contraindications