In order to engage in independent manufacture of concrete pillars for the fence, there are several significant reasons.

The first is a significant savings, since the price of such structures is 30-40% cheaper than factory concrete column columns.

The second reason for the popularity of the manufacture of pillars with their own hands is the possibility of free selection of the size and shape of the transverse section. This is especially convenient and justified during the construction of non-standard fences, installation of wickets and gates.

In addition, standard concrete poles, as a rule, do not have mortgage parts.

Therefore, quickly and reliably attach wooden or metal runs is very difficult. In the collisters of our own production, the mortgage parts can be accommodated at those points where the attachment scheme you selected is required.

The main condition is a high-quality formwork

It is no secret that concrete poles for the fence are obtained durable and smooth only when a good formwork is made for their casting. Therefore, you should not save on this design. The more carefully you will do it, the more pillars will come out of it.

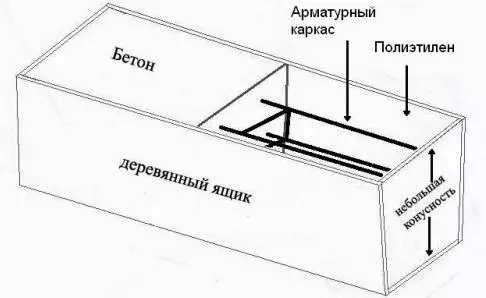

The easiest variant of formwork is a wooden box design . Three sides and ends are made from planed boards, and the fourth is left open under the fill of the concrete mix.

In order for the cement milk to emerge from formwork, the boards should be carefully adjusted, and even better - lay the polyethylene film inside the formwork, the glue or to bond its walls with plastic. Such protection will save the formwork from deformation and swelling. It is a smooth non-water-absorbing walls behind the walls very easily, so there will be no problems with the disassembly of such formwork.

Collect the design from the boards is better on the screws, because, unlike nails, they can be easily removed without damaging the board.

Article on the topic: Cabinet with your own hands: Scheme assembly door cabinet coupe

Option forms for concrete fences

Without fittings there will be no strength

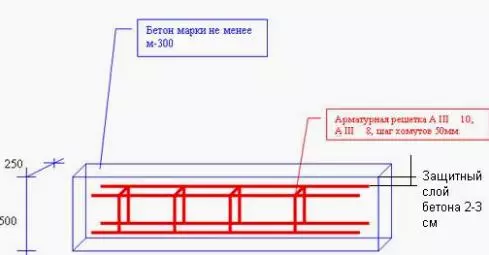

In order to make the pillars for the fence from concrete, it is necessary not only to use a strong solution with a ratio of cement to sand 1: 2 or 1: 3, but also to prepare steel reinforcement.

Since the concrete pillar works not only on compression, but also to bend, then the fragile concrete without the reinforcement frame will not be able to ensure the stability of the fence.

Therefore, pre-prepare a household welding machine for the assembly of the steel pillars. For the manufacture of the frame, it is enough to weld a bulk grille of 4 longitudinal rods with a diameter from 12 to 16 mm with a distribution reinforcement in the form of short rod segments with a diameter of 8-10 mm and a step from 5 to 15 cm.

By installing the reinforcement frame into a wooden formwork, do not forget to leave the gap between it and boards at least 2 cm. It will fill it with a layer of concrete to protect the metal from corrosion.

Cooking concrete for pillars

After the formwork is assembled, and the frame is installed, it should be properly prepared a concrete mixture. The aggregator should not be too large for it, since the transverse size of the poles is small. Therefore, buy a small rubble fraction 5-10 mm.Mixing the concrete mixture (better in the concrete mixer, rather than manually), you can begin the fill of the form. Remember that it is not enough to simply pour the pillar concrete, since it is formed in it a lot of air shells that reduce strength.

Therefore, after performing the fill, be sure to suck formwork . Singing, the concrete mix will be much more dense and outstretched air. For this operation, you can use the usual perforator in which the reinforcement rod is installed with a stubborn area welded to it. Attaching the perforator to different parts of the wooden formwork, you quickly and qualitatively compact the concrete mixture.

Article on the topic: Retractable bed do-it-yourself: Production sequence

If you do not have a perforator, then you must "stop" the bolted concrete with a short segment of the reinforcement.

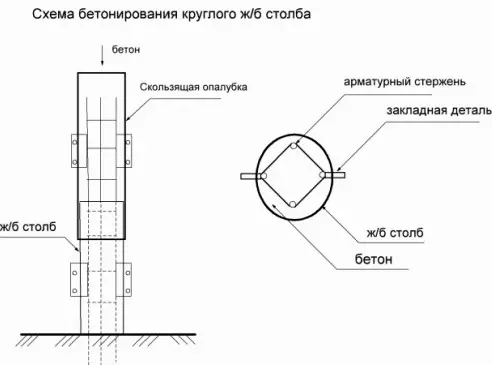

Round poles

Anyone who wants to cast out is not square, and round pillars, can do it right on the place of installation of the fence. This will require a formwork from a metal pipe. This technology is very convenient because it allows you to immediately cast and underground and overhead part of the post without its carrying and editing. By installing the reinforcement frame in the pit, it is filled with concrete to the surface of the soil.

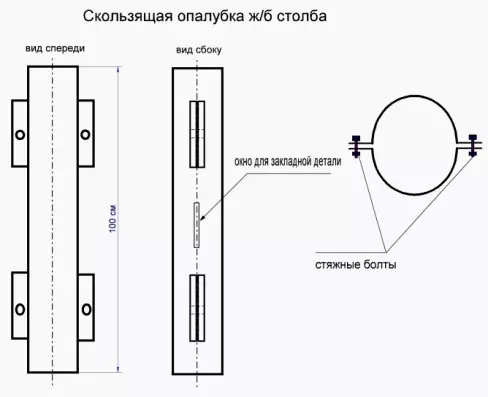

After that, the manufacture of concrete pillars with their own hands lead the method of sliding formwork. For this, the pipe is cut along two halves and welded kinks with holes for tie bolts. Formwork from the pipe does not need to be done too long, it will be quite enough and 1 meter. For easy disassembly, both halves of the formwork from the pipe are lubricated with machine oil.

After assembling and installation on the ground, you need to output the vertical of the formwork using the level. On the eye here it is impossible to work here that the pillar does not go to the side. By filling the formwork with concrete, it is compacted by vibration and leave for 3-4 days to gain strength. After that, the bolts are slightly weakened so that the formwork can move, and raise it upwards. After that, the concrete operation is repeated.

On this technology, decorative concrete pillars, which look original and aesthetically look. To do this, the layer plastic with an embossed texture under stone or wood is laid into the formwork.

Mortgage details - Ease of installation of the fence

High concrete strength guarantees pillars durability, but at the same time complicates the installation of the fence structures. In order not to make special clamps and screeds for fastening the spans of the fencing of the site, you need to put the installation parts in them before casting the posts.

The easiest option is to lay in the ZHB poles of the antiseptic wooden bar. If it is assumed to install steel runs under the professional flooring, then to the reinforcement framework to concrete, the mortgage parts should be used. It can be a hairpin with a carvings or a steel plate to which carrier fence structures will be welded.

Article on the topic: Curtains of two colors in modern interior design

Useful video on the topic: