The invention of the set of fences from concrete does not relate to the epochial insights of the human mind, such as fire, powder or wheel.

Unknown to the world, the creator of eurofacle simply and reliably solved the problem of docking concrete pillars with fencing plates. Maybe, at this point, he remembered the children's toy "pyramid", in which multicolored rugs are riveted on the central rod.

Or was simply an inventive person and realized that the best replacement with mortgage parts and welded for fastening the concrete slab is a rectangular groove in the post.

Whatever it was, but concrete eurofaculation quickly gained popularity from developers and became one of the most common startups of his own business.

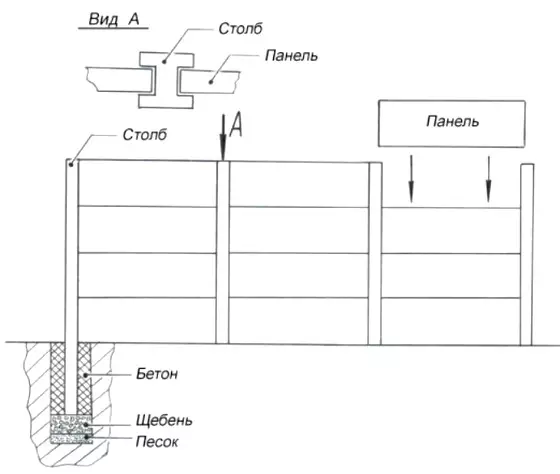

The principle of erection of such a fence can be easily understood by looking at the scheme of its installation.

Morning circuit

In concrete pillars, each of which has two longitudinal rectangular grooves, the panels are inserted from top to top. To eliminate overturning, the fence racks put in the pit and poured concrete.

Types of eurofacies, sizes of panels and columns

Without changing the principle of installation, manufacturers offer two varieties of eurofacies:

- Unilateral.

- Double-sided.

This division refers to the location of the texture pattern. In one-way panels embossing, imitating brickwork, stone, wood or siding is applied only on one side. Double-sided plates are decorated with a textured pattern on both sides. Having bought them, you do not have to solve a difficult dilemma: "The fence looks great from the street, but does not aesthetically look like from the courtyard" and vice versa.

The second conditional division of eurofacle is connected with the appearance. They can be smooth or with a relief surface.

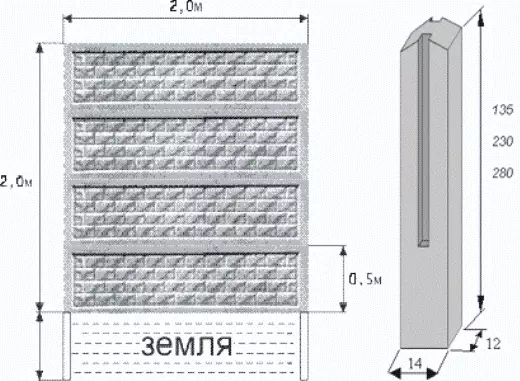

The third classification feature refers to the size of the structural elements. The panels have one basic standard: 50 cm width with a length of 2-2.05 meters. The thickness of high-quality unilateral plates is 4 cm, bilateral - from 5 to 6 cm.

Common size of the structural elements of the euro

The case is more complicated with pillars. Most of the manufacturers were determined with their thickness (12x12 cm, 12x14 cm or 14x14 cm). There are no single standard for the length. In some firms it is 135, 230 and 280 cm. Others make pillars with a height of 145, 210 and 260 cm. The confusion occurs due to the different length of the mounting end (part of the pillar that has no grooves - for the standard fence most often 70-80 cm ) concreted in the ground.

Article on the topic: Alignment of Paul under Laminate Plywood

Therefore, when buying, we advise you to navigate to the height of the fence (two panels - 100 cm, three panels - 150 cm, four panels - 200 cm, five panels - 250 cm) and buy pillars that have the length of the mounting end more. It is also worth noting that you can find extended column variants (up to 4.1 m - 6 sections) and panels (up to 2.55 m) on sale.

Production technology

The process of manufacturing sections and pillars of the euro is characterized by simplicity and minimum equipment.

To organize the production of unilateral plates and pillars, vibrationtole, concrete mixer and fiberglass form are required. The initial raw material for the preparation of the injection molding mixture is the cement of the brand 500, fine crushedbon (fraction 5-10 mm) and washed river sand.

The rubbank is placed in the concrete mixture, poured with water and include for several minutes for flushing. Removal of pollution along with water, sand, cement and clean water in a certain proportion are added to the rubble. A plasticizer is introduced into the solution during the kneader - a substance that enhancing the convenience of concrete. Alkali-resistant pigments are added to the solution for color plates and columns.

Forms before filling are lubricated with a special polyester lubricant or a mixture of engine oil and gasoline (1:10). By placing the injection molding into a hard frame stretcher, it is put on the vibrotol, it is tightly filled with fresh concrete and placed the steel reinforcing mesh (the diameter of the rod is 4-5 mm).

In the process of vibration, shrinkage of the mixture and its seal occurs. Forms are continued until concrete compares with its edges and air bubbles will stop out of it. After that, the surface of the future plate or post is spilled by the rule and the skeleton-stretcher is reforming.

Some manufacturers take out the plates and pillars from the forms not immediately after the vibration absorption, but give concrete for several days for "maturation". This method improves the quality of the finished elements, but it requires more plastic forms to work.

The time required concrete for a set of varying strength depends on the air temperature and on average ranges from 3 to 4 weeks.

The technology of making eurofacares with a two-way textured surface is not fundamentally different from the considered. The difference lies in the design of the external frame. It is a hermetic vertical formwork, inside which are two forms. Filling them with concrete is also conducted on vibrationtole. In this case, it is poured on top into a narrow slit between the walls of the formwork.

Article on the topic: How to choose a lamella for vertical blinds?

For easier extraction of panels, shapes are supplied with small air holes. It does not give a vacuum to form between the surface of fresh concrete and wall shape. Before starting the vibration, the holes are closed, and after its completion open.

The simplicity of technology and the availability of the working equipment are based on the idea of the possibility of self-made eurobor. The answer to it is ambiguous and depends on the number of plates and pillars that you need. If we are talking about several dozens of structural elements, it is better to buy them from the manufacturer. If a few hundred bills and sections are required for the fencing of the site, that is, it makes sense to buy equipment, forms for the euro and make it all with your own hands.

Note! The video presents an example of an invalid economy on reinforcement, when instead of the mesh in concrete, individual pieces of wire are laid. This significantly reduces the resistance of the panels to the shock and deformation loads.

Features of installation and installation of euro

Step-by-step instructions for newcomers on the installation of eurofacing looks like this:

- There is a line of installation of the future fence. For this, in the corners of the site, stakes are clogged and stretched between them cord.

- At the point of installation of the angular pillar, the pit is digging or a hole is a hole with a depth of 70-80 cm (depends on the length of the mounting end of the pillar).

- A mixture of crushed stone with sand is poured into the well to create a drainage intake with a thickness of 5-7 cm.

- The first post is put on the subfolder, after which its verticality is checked in terms of the level, and according to the roulette - the height above the soil. Temporary mounting of the angular pillar is performed by broken brick or stone.

- A concrete is poured into the well with a pillar and give him a few hours to set.

- 206 centimeters are postponed from the center of the pillar and in the resulting point on the line of the cord, the second pit is done and there is a subtype.

- Taking the lower slab of the euro-feeder, it is put in the groove of the first robbed post. (The depth of the groove 4 cm, the stove should go to its depth of no more than 3 cm).

- Aligning the concrete slab on the cord, the pillar is put in the second pit and they put it on the slab so that it enters it into 3 cm.

- The pillar is fixed by broken bricks, but concrete is not poured.

- From the center of the second column again measured 206 cm and drill the pit.

The described mounting cycle is repeated until the last pillar is set.

After the installation of the bottom row sections is completed and check vertical verticality, the erector installation continues. The remaining plates are put in the spans. For this work will require at least 3 people. The panel is raised to the height of the fence and carefully hardened in the poles of the poles. After filling out all the spans, you perform the final check of the accuracy of the installation and pour the poles concrete.

Article on the topic: Pros and cons of single-circuit and dual-circuit gas boilers

In the photo, horizontal joints are stunned correctly, but to use a solution to deploy the joints between pillars and panels should not

Regarding the shuttering of the joints with a solution of one-sided panels, you must say the following:

- You can close only horizontal joints of the panels.

- Docking plates with pillars should not be chopped with a solution. The hard contact of the solution and concrete violates the process of uniform temperature-deformation shrinkage of the euro and can cause the destruction of the panels.

If there is a "backlash" between the plates and pillars, then experts are recommended to eliminate it at the expense of wooden wedges.

Since many manufacturers produce unpainted concrete sections and columns, then developers are interested in the possibility of their independent painting. For this work, silicone or acrylic paints are optimally suitable, resistant to weathering. Coloring is most conveniently carried out with the help of a spray gun and compressor.

Useful tips when buying euro-free

Pores on the panel - marriage sign

- High-quality panels and columns can be distinguished by a homogeneous glossy surface. If numerous pores are visible on the front side, then such a concrete will not last long.

- The weight of the plate is another sign that you can distinguish a good product from the bad. The high-quality one-sided panel weighs at least 60 kg. Little weight indicates that the manufacturer saved on the rubble and increased the share of cheap dropout or sand.

- The thickness of the panel (in the thinner) should not be less than 3.5 cm.

Approximate prices

To simplify the calculation of the value of the structural elements of eurofacle (sections and columns), manufacturers indicate the price for 1M2 fencing. Multiplying the length of the fence at its height, you immediately see the total cost of materials.

The estimated price of one square meter of one-way eurobor is 650 rubles. The price for 2019 1M2 bilateral concrete sectional fence begins from 1300 rubles.

Rates for the installation of eurofacies start with a mark of 350 rubles per m2. The final amount is negotiated with the customer individually (taking into account the type of soil, the slope of the site and other factors affecting the labor-intensiveness of the work).

The average cost of standard fiberglass form (2x0.5x0.04 m) is 2500 rubles.