To date, industrial or household wiring is divided into two types:

- Hidden wiring.

- Outdoor installation of wiring.

Each species is individual. Therefore, it can be sold separately: junction boxes, sockets or switches. When installing, many masters pay their attention only on the design, but it is completely wrong. Attention should also be paid on the features of mounting sockets and switches on a variety of surfaces.

Features of mounting outlets and switches on different surfaces

Here is a list of basic requirements for which you will need to pay your attention:

- Contact compounds providing electric current.

- Sturdy electrical insulation of current-handed livers.

- Safety of further operation.

These are the main factors to choose correctly. If you exercise their correct selection, then the further use of sockets and switches will not bring any problems.

Installing outlets and switches in hidden wiring

Walls made of concrete slabs, brick or aerated concrete

In the old buildings, the builders have previously created special channels inside walls. In the future, in these channels, experts started wiring and installed metal boxes with switches or sockets. The fastening took place with the help of alabaster, since after drying it ensured reliable strength.

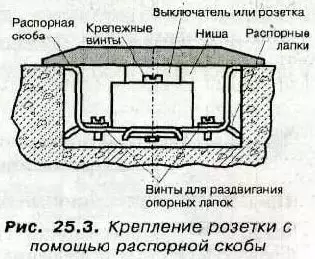

Fastening with a spacer

Internal fastening of the switch also took place on this technology. Now the technology has practically changed. The only feature is that instead of metal boxes use plastic. They have good dielectric properties and resistance to fire. In addition, after expanding the metal brackets, a solid connection is formed in a plastic case, which will ensure reliable fastening of the socket in the wall.

Article on the topic: Balcony laundry dryer

Installation box for outlets and switches

Now many owners of old apartments change wiring and pave a new one. To pave the wiring in concrete where there are no holes, you need to use strokesis. We already have an article how to use this tool. According to modern requirements for each electrical instrument, it is necessary to lay a separate outlet. Due to this, you can reduce the load and improve further quality of use. After the installation hole is ready to enter the conversion with the cable and fixing solution.

When the mixture freezes it can be started to mount a socket or switch. Fastening of sockets or switches occurs with screw screws.

Walls, Ceramic or Gypsum Coating

If the wall is placed in ceramic tiles, then the installation of the socket or switch sometimes is problematic. There is always a big risk of damage to fragile surfaces. To date, many electricians can refuse to perform such work, as they do not want to work with a fragile material.

Drilling ceramic tile

However, it should not be afraid of this work, since there is a special tool that will help in this. First you need to mark up. After that, you can proceed to drowning holes in ceramics. You can make it with winning drills or crown with diamond spraying. When all drilling work will be completed, you may need to remove the remains of the tile with a chisel and hammer. It should also act in this case, as if you do not calculate the power, then the tile can simply burst.

Tripping holes in the tile

When the internal space of the tile is removed, you can proceed to burn sharp edges. For this, in most cases, experts use the emery circle. Now the stages of work will be the following:

- Drill holes in the released concrete. At the same time, remember that it is prohibited to concern the treated edges.

- Consolerate concrete under the tile. First, use a small diameter drill, and then expand the hole. Use thick drill is not immediately recommended due to increased loads.

- Remove the excess concrete between the drilled bodies.

Article on the topic: Partitions in the bathroom - stylish and functionally

To fulfill work with ceramic tiles, it is best to use a professional perforator, since the shock drill simply cannot cope with such loads. When the extra concrete is eliminated, you can start installing boxes for a socket. If the box is installed at the place of the old outlet, then the task will be much simplified. After entering the cable it will be seen in the prepared hole. To capture, you can use the usual homemade hook.

When the putty, which was used for mounting, the peasant will freeze, can be processed. If the installation quality fully satisfies, then it will be possible to start installing the decorative lid. After completing all the processes, do not forget to check the performance of the outlet or switch.

Sometimes electricians forget to check the installation. Search for a fault when all the steps of the installation are completed will be much more complicated. To connect the ends of the wires, you can use heat shrink tubes. These elements allow you to provide more reliable protection. Also, if necessary, WAGO terminals can be used. Further check of the phase wire will be carried out using an indicator screwdriver.

Walls with plasterboard partitions

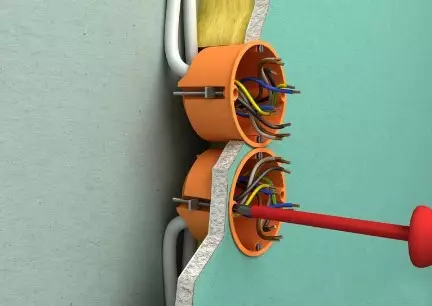

Installation of outlets inside thin-walled structures occurs equally. To install a socket or switch in plasterboard, use special submersers. They have large ears that allow us to provide reliable fastening. To install the pickle in the drywall, it is first recommended to cut hole with a crown.

Installation of converter in plasterboard

After that, you can install the box and securely secure it. Then you will have to start the cable and connect.

Installing outlets and switches in open wiring

On this method of attachment you will need to pay special attention. To ensure the installation of outlets to building structures, you must use open wooden peavernacles. These are cut wooden discs that have a rectangular or rounded shape. In the factory conditions, these installation plates will be impregnated with a protective composition that will be resistant to ignition.

Article on the topic: Electricity from the air

Wooden peaped for open wiring

Also, such products can be made of polystyrene, genitax or other non-combustible materials. Fastening to the wall occurs with the help of screws or by gluing. On wooden surfaces can be installed additional protection, which has a thickness of 3 mm. The housing with the mechanism of the socket or switch can be mounted to the installation conversion with two ordinary screws. If you use secret models, then their canonical ending during twisting will crash into the hole and will push the case material. As a result, the corps simply burst.

If the fastener is not tightened to the end, then over time he can fall out and disappear. At the exit site of the wire from the socket, it is necessary to break down a small piece. Otherwise, the socket will heat the wire and disrupt its integrity.

Socket on a wooden wall

Old rosettes can have a rather fragile body. Therefore, it is best to acquire modern options from the best manufacturers. You can get acquainted with the full list of the best manufacturers in our articles. Now you know what the features of the installation of sockets and switches on a variety of surfaces. We hope that this information was useful and interesting.

Dimmer device.