Table of contents: [Hide]

- Processing of seams and castle connections

- Polyrol for laminate

- Deep Damage and Restoration of Lamella

Laminate occupies a leading position in popularity among floor coverings. It seems he is good. The wide palette of colors and a variety of drawings allows you to choose a coating for every taste and even easily imitate the parquet board of the most sophisticated tree species. During operation, the laminate does not require special attention or relationship, and the departure is characterized by simplicity. So such a coating seems quite practical. And if you compare with other materials (for example, with parquet), it is also very democratic on the price characteristics. But it will be possible to enjoy the floor from the laminate without unexpected surprises only if all the rules for laying the laminated board will be met and the necessary processing is performed.

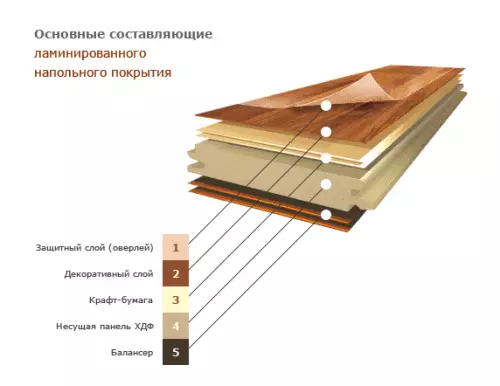

Laminate Board Device.

Getting Started, prepare the following:

- respirator;

- protective gloves;

- Rubber spatula;

- sponge;

- Soft fabric.

Processing of seams and castle connections

Laminate refers to wear-resistant coatings. For premises with an increased load (permeability), it is assumed to use a higher class of strength laminate. But even in this case, it should not be forgotten that the locking compounds of the laminate remain the most vulnerable areas, and therefore require themselves more thorough and careful attitude at the assembly stage.

Castle compound treatment with special wax allows to achieve a more dense compound and protection of seams from aggressive mechanical effects and penetration of fluid when it is on the surface of the laminate.

With the help of special wax pencils, laminate seams are protected from negative impact (shocks, wetting, heating).

After processing the lock connections, it is necessary to lay a laminate, observing the usual rules of flooring flooring from the laminated board.

Article on the topic: How to make a transformer table with your own hands?

You can find on sale laminate with high compounds. On the one hand, it is good - you do not need to spend time on the processing of seams. On the other hand, such a laminate should be chosen more carefully, because with the help of wax, the manufacturer can hide small production defects of the laminated panel.

For the treatment of laminate after laying, special mastic and emulsions based on wax, paraffin or polyurethanes are used. The task of such means is to strengthen the castle compounds, the creation of a protective film on the floor surface. The protective coating protects against the penetration of dust and moisture both into the surface of the laminate and in the seams between the panels.

Before processing the laminate immediately after laying, the surface must be thoroughly speaking to remove even the smallest trash and dust particles. Otherwise, all this together with mastic will fall into the seams between the panels.

Materials based on beeswax or other natural wax components are recommended to use only for processing seams and castle compounds. This is due to the fact that the wax leaves on the laminated surface of the spots. Therefore, the rainfactory wax mastic should be applied in the required quantity in the location of the laminate board, the surplus to remove and polish the processed connection. After 4-5 hours, it is necessary to polish the entire floor. It is important to remember that such work can be carried out only in the respirator to protect the respiratory tract from harmful evaporation.

Back to the category

Polyrol for laminate

Thanks to the polishing of the laminate, with the help of special means you can hide small flaws of the floor, as well as give it shine and novelty.

To protect the laminate immediately after laying, as well as to refresh the already operated laminated flooring applied polyroli. These tools can be both in solid state (mastic) and liquid and in the form of spray. Regardless of the state, the polyrolol does not require thorough rubbing into the floor surface. Only in the case of the treatment of the floor, which has damage and traces of wear, is precisely problematic places worth paying more attention. For applying the means, a sponge will fit, and for polishing - soft fabric. The remedy needs to be applied along the lamella, then the color will be homogeneous, without spots and divorces. It should be noted that applying mastic or emulsion requires a lot of time and effort. It is easier to cope with water-based emulsions that need to be divorced in water and simply wash the floor with a solution. It is clear that in the first version, the costs of the strength and time are justified - the effect of the treatment of the floor with mastic is much better than the simple wash with a water-based emulsion solution.

Article on the topic: How to paint the slopes on the windows in the apartment with your own hands?

The laminate processing agents are matte or glossy (like laminate). It often happens that people fascinated by the glitter of glossy laminate choose such for their premises, and then they are looking for ways to make it matte, but it is impossible. Matte mastic is not suitable for glossy laminate: after processing matte mastic (emulsion), glossy laminate is unevenly covered with divorces and looks untidy.

Means for processing laminate immediately after laying and to maintain a fresh, attractive type of floor covering is enough to be used twice throughout the year. They have high resistance to abrasion and burnout under straight sunshine. To preserve the coating, it is necessary to avoid using funds for general cleaning.

Back to the category

Deep Damage and Restoration of Lamella

To repair chips and deep cracks in the laminate uses wax and wipel. The crack is filled with a crack, and after drying over it is applied wax.

If in the process of laying the laminate due to careless appeal on its surface, scratch was formed, then before processing the entire surface, the scratches should be treated with a special wax pencil. It is possible to use the wax pencil to restore the laminate if chips were formed during operation (for example, from falling on the floor of sharp objects). If the damage is deep, then the wax must be applied in several layers and let it be a good to dry each of them, and then polish well. For the restoration of damage to the solid wax pencil, the wax must be predicted, and then smeared damage and give dry. Before processing damage to wax laminate, you need to carefully clean and degrease. Pencils are of different colors and the effect of painting the color depends on the perfect hit in the color of the scratch will be completely imperceptible.

Laminate is a beautiful and practical floor covering. Laying takes a little time, and the properly selected for the design of the interior on color and texture laminate looks good and expensive. Caring for such a coating does not require special skills. And if after laying to take care of the protection of seams, to treat laminate with protective means, then it is not terrible, neither wet cleaning, nor wet shoes after the rain and snow. In time, handle the laminated floors and will last will serve for a long time without delivering the hassle.

Article on the topic: Toilet finishing with plastic panels: interior design photos