By the way, a very important point. Before starting to make any bed, you need to know the exact dimensions of the mattress, since the length of the standard mattress can be 1900 mm.

Bed with laundry boxes do it yourself

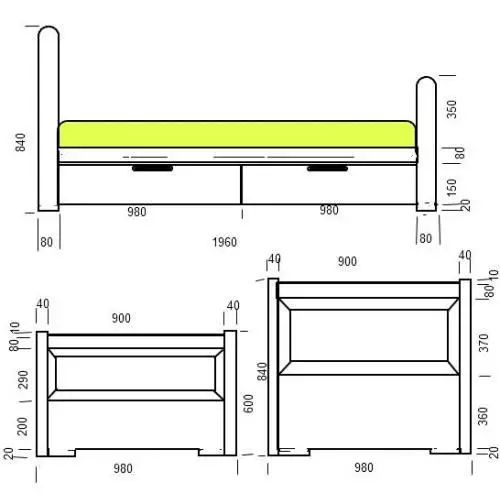

Backrest bed . The big back will have a total width of 980 mm, and the height is 840 mm. If we talk about small, then its dimensions: 600 mm in height and 980 mm wide. The thickness of all parts will be single - 40 mm. For a better understanding and presentation of all parts and size ratios, see the detailed sketch above.

The backs can be issued in two ways:

- Insert the fillets of the classic look.

- If there is a manual milling mill, you can make a backrest from a solid shield, and then make horizontal grooves using an end profile cutter.

Assembly method . At first, on all end parts of the back is done by a manual spike milling mill. If you use a fourth mill with 15 mm depth to the support bearing, then the spike is obtained in size 15x15 mm. You can successfully apply the fourth mill with a 10-millimeter depth.

Vertical bars on backs - 40x80 mm, 840 mm rack in height for a large backrest and 600 mm - for small. The racks are closed on top of the plastic, and in the upper end and the edges are injected.

The bed is furniture for leisure and sleep and therefore, it must be comfortable for use and not have sharp corners to accidentally not be injured. Therefore, the upper facet of the backs and side linings is also injected. In the lower and upper horizontal bars, a groove is done to install Filong. The groove can be made of 15x15 mm. From the end sides, horizontal bars backs and fillets are equal. Do not forget to add two depths of the groove to the altitude and take away 4 mm.

Article on the topic: Wallpaper with trees on the wall will create an amazing atmosphere of rest and rest

Probably the most difficult point from a technical point of view, will pass on the backrest racks, which should be as a result of a depth of 17 mm and a width of 15 mm. From the bottom of the shields it is necessary to install the legs with a height of 20 mm, a length of 150 mm and thick, as the back. After completing the assembly, they can be placed on glue and tighten with self-drawing.

If we talk about the grooves, it is better not to make them through, and retreat from the ends of the struts of both backs of 30 mm, therefore, the spikes on horizontal bars must be made in the dark.

The grooves can be done on a stationary freser and on hand, there is almost no difference. When the groove is selected, then use the end milling mill "barrel", the standard guide milling is leveling.

The following sequence of work is recommended:

- Go through the cutter on the central part of the bar of the back.

- Shifting on the guide mill, that is, reducing its length, slowly pass the groove on both sides of the bar until the required width of the grooves is obtained.

There is another method that consists in passing the groove on the circular saw, when the saw was in 17 mm in the exhibited height.

It is necessary to act in this case as it is more convenient to you:

- To set the circular guide in such a way to go first in the center of the bar, and then, the guide to gradually move and pass it from both sides.

- Immediately set exactly the guide and make extreme cuts strictly in the width of the groove. Of course, the second method is more difficult, but maybe it is right for you, here is a matter of taste. According to the experience, it can be said that for a conventional saw with a width of 5-4 mm, the guide will need to be rearranged about 3-4 times, which is not much.

After the spikes are made, you can glue the grooves of the back, only be sure to squeeze the product in the bats. If the spike made, due to the size, does not cause big trust, you can strengthen the collected parts by self-draws - two below and two at the top of each back. Hats of self-tapping screws need to drown and close with wooden plugs. On each back in the end, the eight sams are fixed. Conveniently in this case, apply the screws with a diameter of 5 mm and a long 70 mm having large caps.

Article on the topic: how to make decorative bulk floors do it yourself

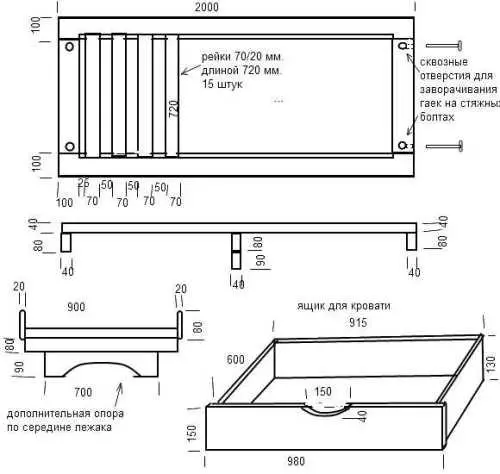

Sunbed bed . It is assembled from bars of 40x100 mm on the spikes and has dimensions: 900x2000 mm and a thickness of 40 mm. On the inside of the long bars is made by a 10 mm manual milling mill in depth. The rails of 70x20 mm and a long 720 mm are stacked in a quarter. The interval when laying the plates is 50 mm. By the way, a quarter can be made without the use of a millingrer, and to apply the bars of 20x20 mm, which should be fixed by self-pressing from the inside of the edge. All connections should be missed in advance by glue.

Side strips 20x80 mm are installed on the outer edges of the sun bed. At the top should form a side who holds the mattress. Side strips are obtained 1960 mm in length, their upper edge is injected. In principle, the planks simply plant on the glue, but for durability it is better to apply the self-tapping screws, and the hats hide under wooden tubes.

Bed assembly with linen boxes

To assemble a bed with linen boxes, 3 brus 40x80 mm and 900 mm in length are necessary. Two bars are installed on the inside of the backs, glued and secured with a long-term 70 mm. The installed reference bars has a height along the top edge of 170 mm. If you add a lounger of 40 mm, then the bed without a mattress turns out a height of 210 mm, and with it - 410 mm. The third bar is installed below, in the middle of the lounger, and is attached by self-drawing through the sun bed.

To build a sun bed with backs there are several ways, but the most reliable, perhaps, is the assembly on bolts having flat hats. The bolts are used with a diameter of 10 mm and a long 100 mm, and their hats at the end of the work are toned under the color of the product. To twist the nuts, it is necessary to drill at a distance of 60 mm from the shelter's ends of the through holes with a diameter of 35 mm. Spin the nuts with a convenient key.

Article on the topic: How to fix chalks for curtains: detailed instructions

Internal horizontal bars have two functions:

- Support for sun bed;

- Place fasteners guides for drawers.

It is better to use telescopic guides, they, in contrast to roller, do not thunder. It is possible to do without guides at all, but make the drawers just roll-in on the rollers.

When the sun bed and the back are finally ready, the bed can be collected by tightening it on the bolts. It is very important to measure the distance between the supporting bars accurately before starting the assembly of the boxes. It is necessary to withstand the size of the width of the planned boxes in order to properly install telescopic guides. It is necessary to measure the thickness of the guides and take two of these thicknesses from the distance between the bars.

The bottom of the box is made of 4 mm thick plywood, which is installed in the grooves on the walls having a height of 15 mm from the bottom edge of the box. The bottom must be strengthened. For this purpose, a transverse rail of 15x80 mm is applied, which is fixed through the walls on the tapping screw. Covers of boxes have a thickness of 20 mm and dimensions of 150x980 mm. Instead of repellent sticks, for which it can sometimes cling to the foot when walking, it is convenient to make in the drawer cutting for hand.

With the opposite side of the bed side boxes, it is necessary to fix the additional bar with a thickness of 20 mm and the size of 150x1960 mm. You can put it on metal corners, although it is possible to do without it, if the bed is moved to the wall.

In order for the bed with time, the bed did not turn around in the middle, and the boxes did not give distortion, you need to put wooden supports with a height of 88 mm, which are screwed from below to the central bruster on the tapping screw.

That's the whole process of how to collect a bed with linen boxes. We wish you success!