Photo

Wooden parquet is one of the most reliable and durable flooring. But all over time wear out and loses its former attractiveness. Shoes, heavy furniture, flooding - all this leads to the destruction of even such a stable material as parquet.

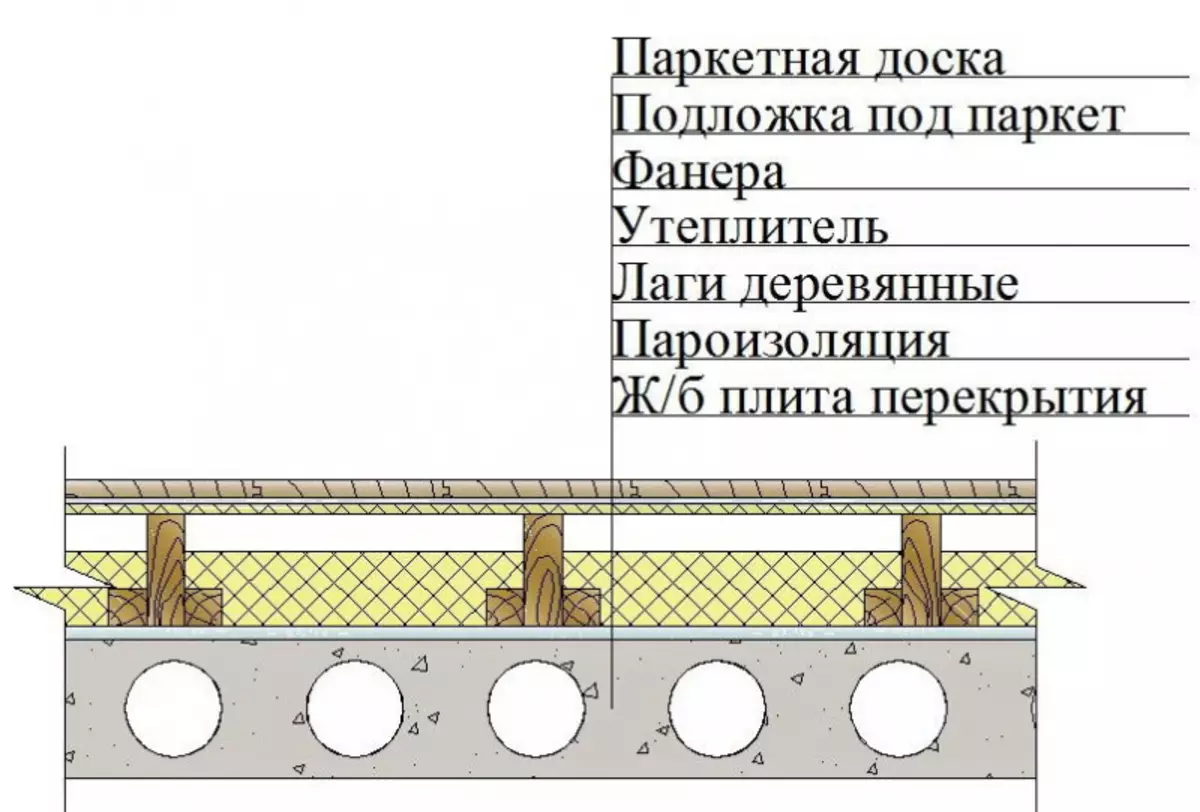

Separation floor with parquet board.

What to do in such a situation? Is it possible to change such expensive coating? There is a simpler exit - the grinding of the parquet with their own hands.

How to polish parquet

Parquet grinding circuit for removing old varnish.

This process includes several stages:

- Dismantling of old varnish.

- Purification of flooring from contamination.

- Floor grinding, in the process of which irregularities and surface defects are removed.

Grinding parquet is carried out before applying a new layer of varnish or toning substance.

If you put a varnish on a non-empty parquet, then all scratches and defects that have appeared as a result of operation will be visible. Therefore, the high-quality grinding of the parquet is the key to the durability and attractiveness of the floor.

But the grinding of parquet also has its own testimony. It makes no sense to restore the old and crashing coating - it's easier to replace it.

Parquet grinding circuit for crack removal and chipping.

When grinding does not save position:

- The material is concerned that the gaps between the plackets of the parquet reach 5 mm;

- Parquet swell due to the flood;

- abrasion of coating in some places and the formation of surface irregularities;

- Wood is amazed by insects;

- appearance in the place of mold;

- Flood wetting due to evaporation from below.

In the latter case, it is necessary to remove the old coating, on the basis of laying a waterproofing film and only then put the new parquet.

All listed problems arise due to improper laying, unreasonable material, severe operating conditions. Grinding of parquet with their own hands eliminates defects in all other cases.

Article on the topic: Design and installation of a lady of shower in the floor under the tile

Before polling the parquet, it is necessary to free the room from the furniture and carefully remove the surface. Plinths should also be dismantled.

Parquet Grinding Tools

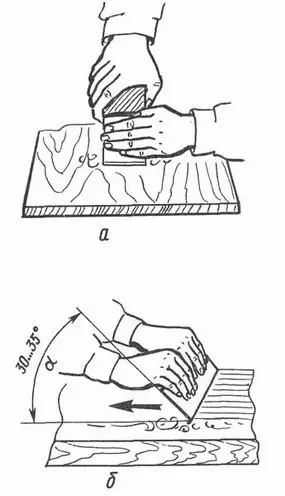

Cyclishing surfaces.

Grinding works can be performed as manually and with special machines. If there is no possibility to rent expensive equipment, then you can use manual cycles. It is a metal plate with a curved and sharpened edge, which is convenient to remove the old varnish.

The cycle allows you to shoot a lacquer to a large depth even in the most hard-to-reach places. But this method of restoration is quite heavy, as you have to do everything manually.

The high-quality method will be the restoration of the parquet coating by means of grinding machines.

The grinding process consists of several stages, for each of which uses its type of equipment;

- Grinding machine for drum type parquet. This mechanism removes the deep layers of the old coating. This machine consists of a reservoir of 200 mm wide and pump, in which the chips are assembled. An abrasive material is attached to the drum, which circles the surface.

- Single-tie and three-discovery plane machine. This equipment is used for thin grinding of parquet in front of tinting or lacquer coating. Such an adaptation is very popular, as it is multifunction and secure. However, not everyone can afford so expensive typewriter.

- Sapochok is a type of grinding equipment designed for grinding hard-to-reach places: under radiators, in the corners. These machines are unified: they are equipped with abrasive circles and a dust collector.

- The industrial vacuum cleaner is designed to remove dust after grinding.

Tools for receiving parquet.

Grinding machines are a comfortable device, but expensive. They are mainly acquired by firms that are engaged in parquet floors. If we are talking about one-time grinding of the house, then it is advisable to take such equipment for rent.

For the surface to be smooth, you will need even additional tools and materials:

- sandpaper;

- putty;

- varnish;

- brushes and rollers;

- rubber spatulas;

- scissors for sandpaper;

- Keys for attaching abrasive by car.

Article on the topic: How to process ends log logs after the construction of the house

Sanding paper will need different grain: No. 40, 60, 80, 100, 120. The area of 20 m² is consumed by one sample, which is refilled.

Spankless fill the seams between the planks of the parquet. This will require about 5 kg of material. Varnish is bought in the calculation of 5 kg per 10 m².

Parpet grinding technology

Grinding works start with coarse processing. To do this, the car is filled with abrasive paper No. 40 and the room is diagonally in two directions.

Drum-type grinding machine moves from the wall to the wall diagonally. In this case, it is necessary to ensure that the processed tracks overlap each other by 5 cm.

Scheme of manual cycle.

The effort with which the machine drum works is regulated by a screw. Performing work, you need to follow the engine load: it should not be overloaded or slowing down.

In country houses, voltage differences occur. If the voltage is low, the engine turnover is reduced. If it happened, it is necessary to reduce the pressure of the drum to the floor, and also turn off the other electrical appliances from the network.

Through the wear of the sandpaper, it should be changed. The coarse abrasive levels the floor and removes pollution. The draft stage should be repeated until the surface is quite clean and smooth. When grinding, a layer of material is 0.5-07 mm is removed. If the parquet board thinner is 2 mm, it is impossible to grind it.

After processing the main area, it is embedded to grinding hard-to-reach places with a special device "boot", the design of which is described above.

When finishing, fine abrasive №120 is used and grinding along the walls. At this stage, small disadvantages are eliminated, after which the surface becomes smooth and brilliant.

When parquet is restored, it can be lacquered. For this material, water-based varnishes are used. This is a mistake, since wood can swell from moisture and stratify.

Therefore, parquet floors should be covered in two layers of solvent-based lacquer, and then water-based coating.

The ideal option will be the applying of primer on the wooden floor, and then the coating of varnishes.

Article on the topic: Distance between pillars of fence

You can also use a solid oil-wax coating for wooden floors. This substance prevents wood swelling. Despite the excellent recommendations regarding this substance, it is difficult to apply it enough and to care for such a coating is much more difficult.

Parquet grinding with their own hands helps to restore the old coating with minimal expenses. This simple, at first glance, the procedure refreshes the floor and gives him former beauty.