For decorative decorative decorative decoration, cement-sand screed is often used. After installation, it sometimes occurs such a trouble: aqueous cracks are formed.

It looks particularly bad when the coating just had to dry, and already crackled hardly all over the surface. At about half of the events, this defect can be corrected. To understand what to do when the cracks occurs, you need to find out the reasons for their appearance.

Causes of cracking

Deformation in the tie of the floor appear for two main reasons:

- Problems with basic floors: It is too thin, inhomogeneous, immature - lead to violations of the integrity of the coating.

- Poor-quality installation of a screed: the composition of the cement mixture, the thickness of the coating, the conditions of frozen, the appearance of shrinking seams.

In the first case, the problems are too serious, and it is possible to fix them only by completely dismantling the screed and bringing the basis for a suitable condition, in the future cementing the floor in the future.

In case of problems in the screed itself, cracks to correct relatively. You can only start repairing that the basis does not have problems, otherwise all actions will not make sense - a poor-quality base will simply spoil the floor again. If there is definitely everything in order with the basis, you can figure out the specific lack of a screed and go to the elimination.

Lack of compensatory seams and damping tape

In the process of drying the screed, its array is experiencing certain loads caused by the voltage from the uneven shrinkage of the cement mortar. The smoothness of this process is influenced by different factors:- Different coating thickness at different points of the floor;

- temperature difference in certain areas of the room;

- Mechanical loads from other elements of the building structure: adjacent rooms and in particular doorway, near which cracks in the screed are formed most often, since the cement in this place dries faster, continuing to test the tension from the adjacent premises.

Article on the topic: Bathroom design with mosaic - discuss pluses and cons

Actually, the screed does not withstand the voltage and is reduced. It is not critical damage and easily smeared with the finish finishing material. However, if there is compensatory seams, this deformation would not appear at all.

The seams are made in the most susceptible to the load of places, for example, in doorways. Thanks to this, the screeds in adjacent rooms dried separately and do not affect each other.

It is also recommended that the absence of a direct connection of the screed with walls is also recommended, since the cement array, expanding, may be damaged and harm the wall. To do this, an exfigging tape is used, sticking to the wall around the perimeter of the room and creating a centimeter gap between the wall and coating.

With a large area of the room, compensation seams are created in a step of five to six meters. It is best to do the seams, duplicating the joints in the main overlap. The seams are sutured with a special tool or a simple grinder, the depth must be 1/3 of the thickness of the floor screed.

Non-compliance with the proportions in the manufacture of a solution

Most often it concerns dry mixes. Despite the indication on the packaging of the accurate ratio of water and the mixture, in inexperienced people there is a desire to dilute the solution more accurate so that it is easier to be applied.

It is impossible to do this, since too liquid mixture will strongly reduce the quality of the coating. The manufacturer accurately determined the necessary percentage of water based on the properties of additives in the mixture, so the instructions should be observed exactly.

It is also important to thoroughly stirrer. Manually do it unacceptable. For mixing, a special mixer or a drill with a suitable nozzle is used.

Non-compliance with the correct layer thickness

- Too small thickness leads to insufficient structural strength and destruction of the coating under the external influence;

- With too much moisture thickness in the screed increases the material resistance, which leads to deformation.

Violation of the process of frost

It is necessary to remember the principle relating to all cement solutions: the more time the mixture will spend in a wet state, the stronger it will become. Violation of this rule and acceleration of springs the screed leads to a significant decrease in its strength, which is why cracks appear.Article on the topic: how to breed the wallpaper glue

That is why it is impossible to allow in the premises of drafts and enter the drying screed of direct sunlight. To increase the duration of the floor, a polyethylene film can be used, which will hold moisture in cement.

Elimination of cracks

If the cracks were formed due to the voltage of the material, they make sense only if the compensation seams are still made. Thus, the floor repair will consist of two parts: the creation of a grid of seams and their sealing, climbing cracks.

It should be remembered that the mixture that stuck the seams should have about the same consistency and the margin of safety as the rest of the screed.

Crack repair technology is as follows:

- In the screed, shrinkage seams are cut at a distance of 5 m from each other, in a third thickness of the coating.

- The seams are sealed with polyurethane sealant.

- Cracks expand by doing shock.

- The shoes are cleaned from dust and concrete fragments, ground.

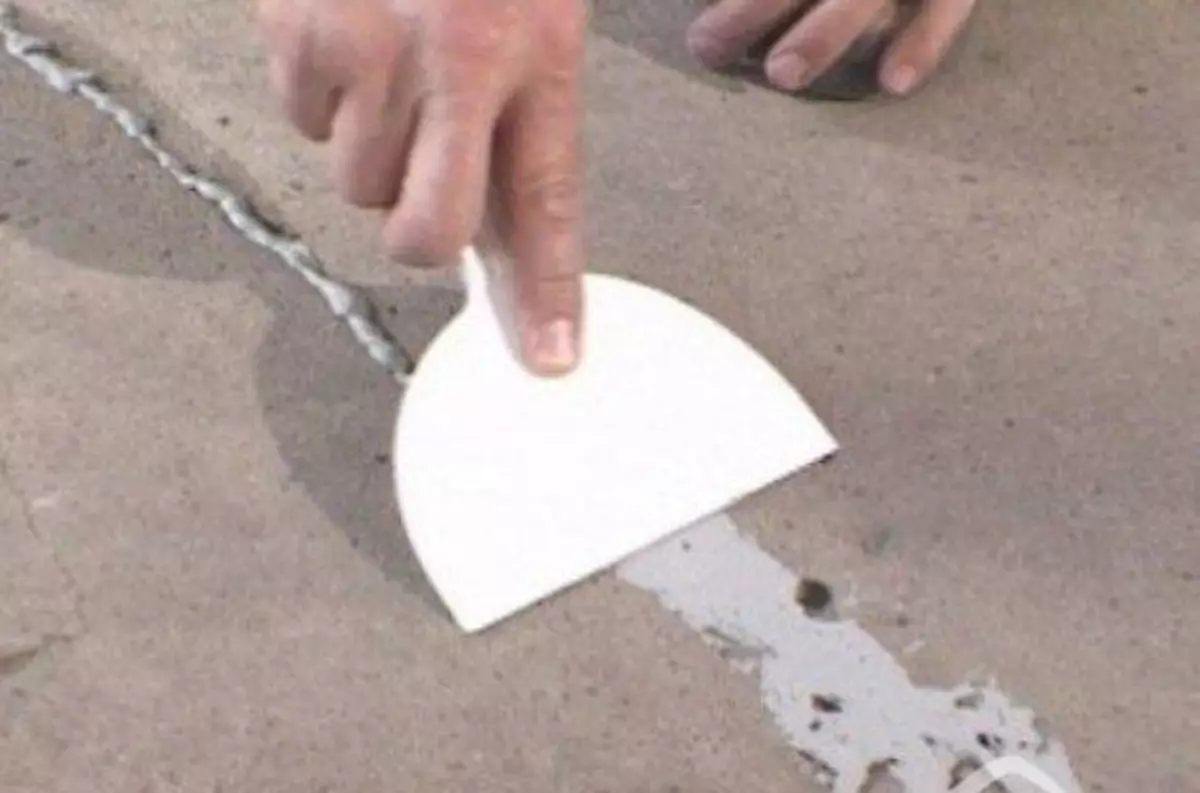

- The gaps are embarrassed by a non-shrinkable substance with a spatula and climb the surface of the screed.

Well suitable for sealing cracks from cement M-400, PVA and water glue. The first two ingredients are mixed in proportions 2: 1, to be in moderation - so that the solution can leak into the slot, but did not grow.

In the case of other types of violations, you need to resort to the help of a specialist to estimate the overall state of the screed - whether it is capable of withstanding the load, whether an acceptable strength is eligible on the base.

If shortcomings are insignificant, deformations can be ignored. It is possible to do this in the case when a tile is chosen as a decorative coating, the glue of which the edges of the cracks will sprink down quite well. In addition, individual elements of the tile coating can be easily replaced if the cracks spread to the upper coating layer.

If the finish finish is another, the cracking of the crack is made in the same way as in the case of seams.

Article on the topic: Proper cabinet manufacture with your own hands

If the structural flaws are significant - the cement layer is too thin or in the solution too much water, and the coating is intended for serious mechanical influences, it will have to remake all the operation from scratch.

Thus, it is fairly easy to close the cracks that appeared in the screed is quite easy if there are no serious disorders in the construction of the base or the cement coating itself. However, the best way to avoid cracks is to prevent their appearance initially. To do this, you can rein the floor screed, and, of course, you need to pay the maximum attention to the installation process and do it with all accuracy.