The rafter system has two types: hanging and inclined. You choose the form depending on the design features of the building structure. Many know that rafters for roofs of private houses are the main element of the structure. To build the roof with your own hands you will need certain knowledge and skills, as it's a completely difficult thing. The scheme of structures and installation of the roof is in several stages. However, if you are not a specialist, then you should not take responsibility for the design of the roof, as you can easily allow an error. As a rule, the designers are engaged in this.

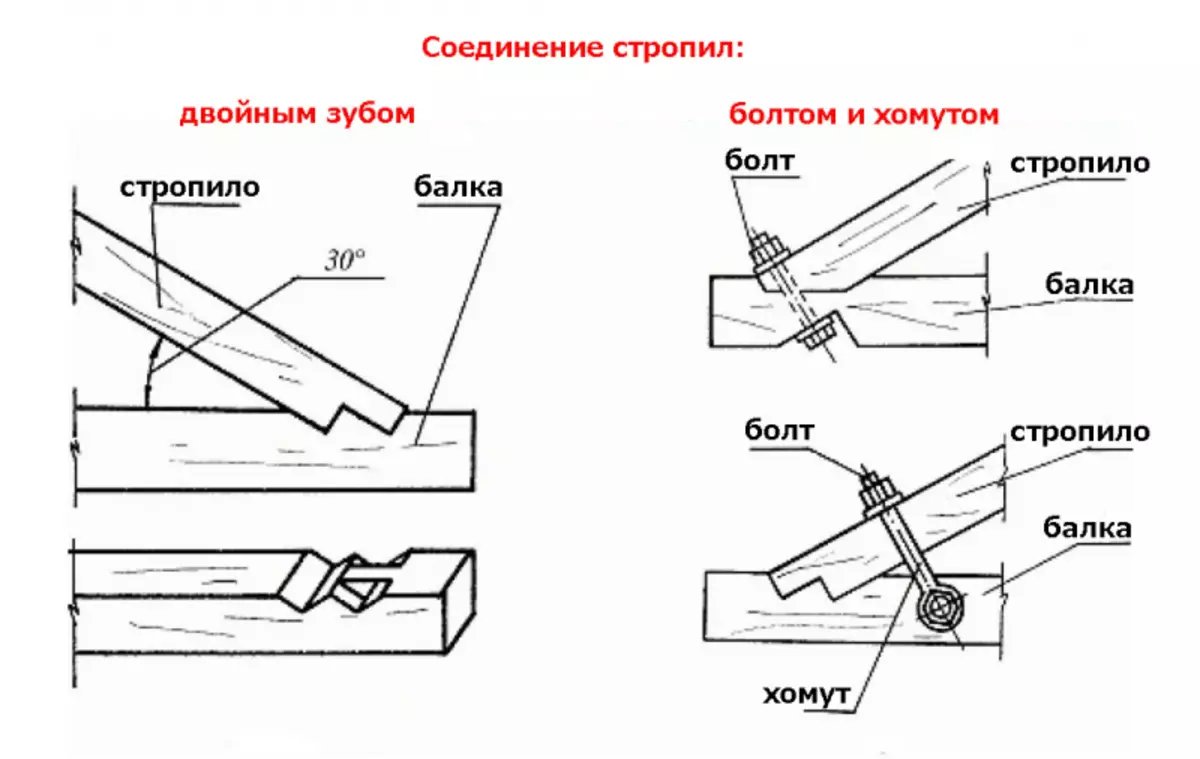

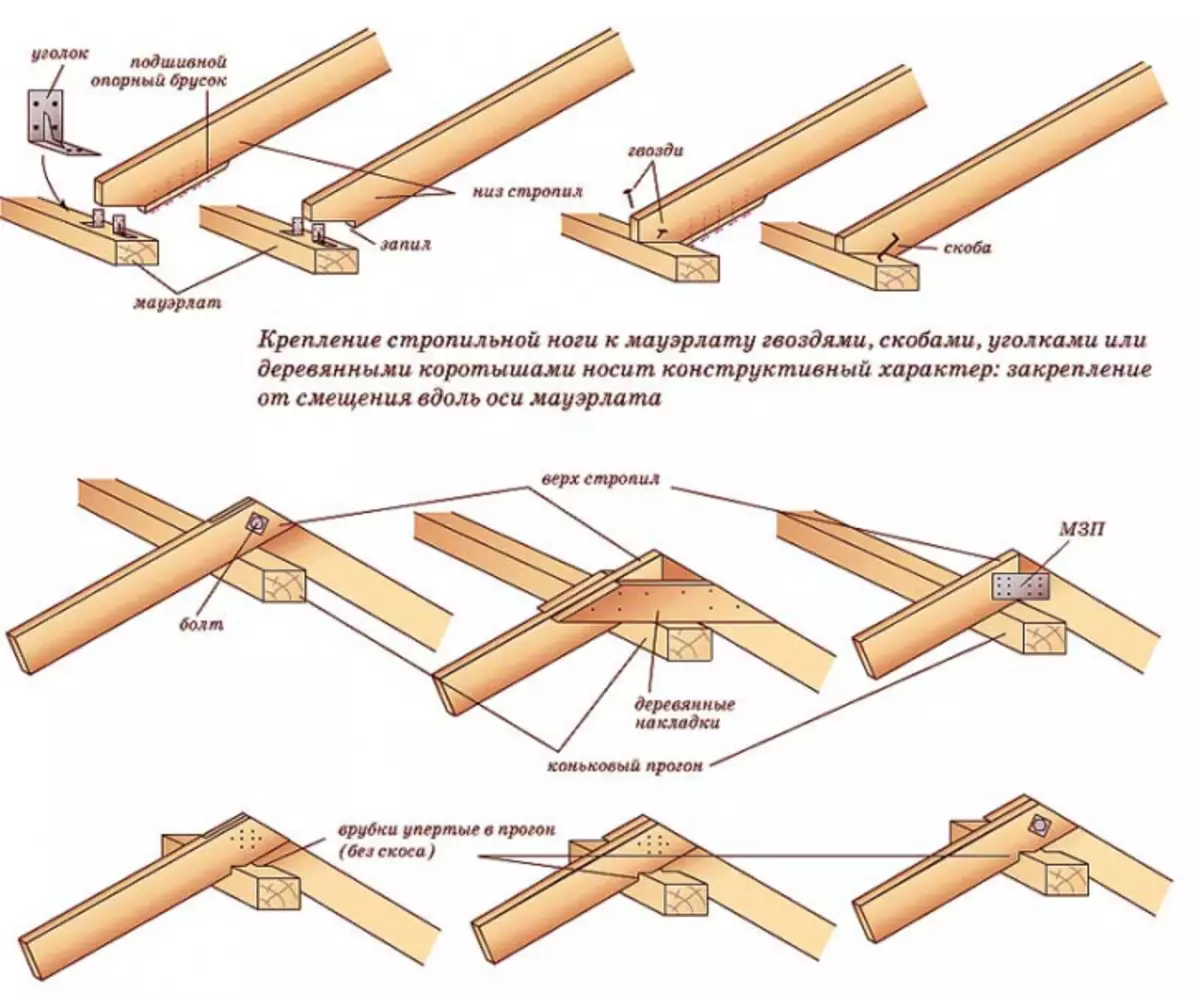

Connection diagram rafters.

What are the types of roof?

Roofs are equipped with any structures in order to protect the inside of the room and the facade from the adverse environmental impacts, including atmospheric precipitation. The roof consists of slopes that have different angles of inclination. The angle is taken on the basis of the climatic conditions of the area and, accordingly, the ideas of the architect. The base of all the roofs - rafters, a doom and roofing coating. However, remember that the rafter system is made only for home, cottage, baths or any other buildings. In the production facilities, the roof design is completely different, therefore it is not worth using one species to all building structures.

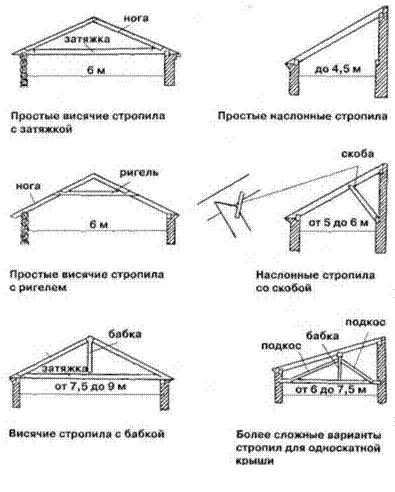

The main types of rafter systems.

Installation and installation work of a similar system is performed with an assistant to simplify and speed up the process. Do not forget about the conjugation of the skates - for each roof it is intended for its type of ribs (formed during the pairing). The pairing is two types: horizontal and inclined. In the first case, this is the top point of the roof, in the second - internal pairing (endands, suspension). By design, the roof can be a single, duplex, four-tie and attic.

- The simplest is a single design. It is a structure based on the bearing walls.

- Duscal roofs refer to more complex structures, which, however, are easy to install. Skates, as a rule, rely on the opposite sides of the walls, which seems to form a triangle. They are called frontons.

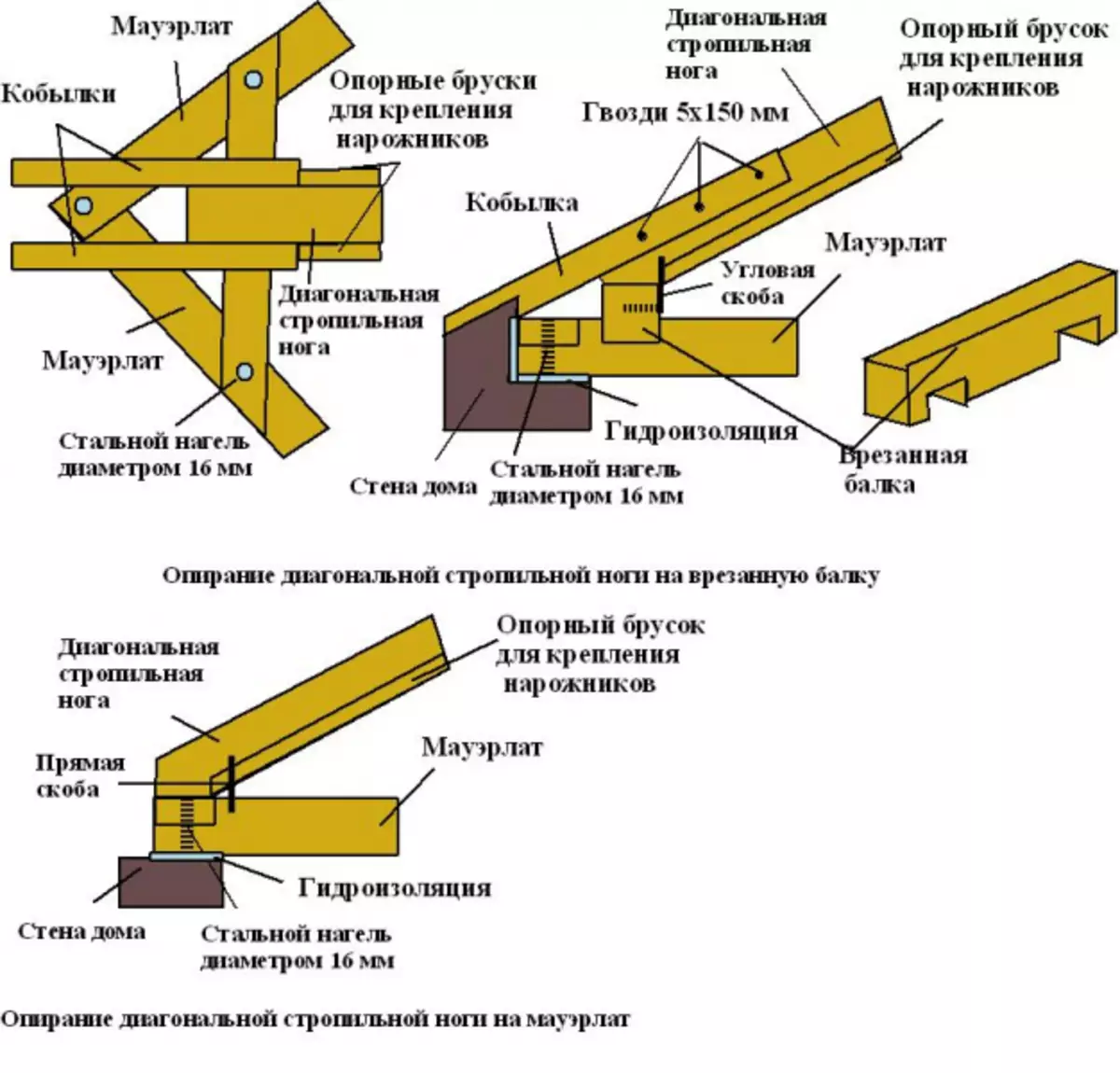

- The third type of construction is a hip (four-tight), represents two skates, but instead of front-line rods are installed triangular, holm.

- As for the attic roofs, here the design is similar to duplex roofs. In a different way, they are called broken roofs. Such a rafter system contains several sections with different angles of inclination.

Article on the topic: Interior of the veranda in a private house and in the country (58 photos)

What is a rafter system?

Device of spots.

The rafting system, with their own hands made, consists of a roofing structure, which has a variety of parameters and features of installation. What is this system? The basis of any roof is rafting legs. They form the rods. In addition, vertical supports are needed in this system together with racks. These elements will transmit any part of the load on the columns or walls for the support.

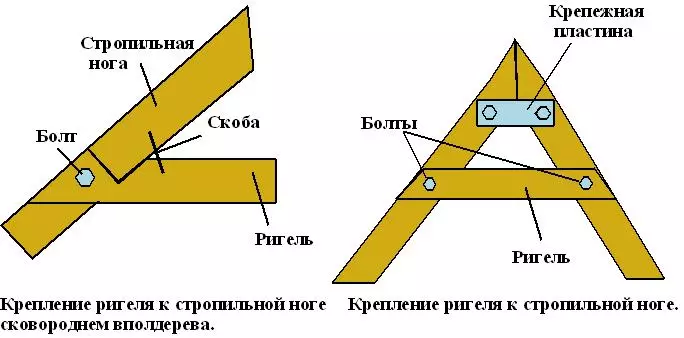

You will need more additional details such as sawmills and inclined elements. They also serve to support and strengthen the design. The tightening in the rafter system is used exclusively to reduce the effort during space. Such a part serves to connect rafting legs with each other. As for the form, the most preferred option is triangular, as it is distinguished by durability and reliability.

Preparatory work on the device of the rafter system

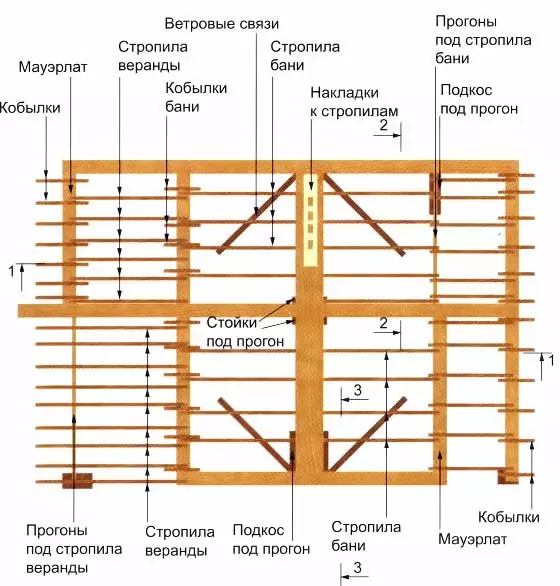

Installation of the rafter system of a four-page roof.

Production and installation of the rafter system begins with your own hands from the necessary calculations and preparatory work. To work, you will need special tools and devices, as well as building material. Experts recommend first to think about the plan of the process of manufacturing rafters. To correctly calculate the settings of the rafting legs, you can refer to the architect. If you want to install yourself on your own, then you should choose the size of the established standards or calculate, based on your knowledge. What should be considered when calculating the parameters of the rafted?

- Roof type.

- View of the coating for it.

- Corner skate.

- Climatic loads (design must withstand them).

What material to choose for the manufacture of rafters? Most often for this case, the wood of the coniferous breed is chosen. Experts prefer wood, as it is easily amenable to any processing and has an affordable price. However, one should not forget that such a material needs careful care with antiseptic drugs from mold and rot. The optimal solution for the manufacture of the rafter - the timber bar with parameters 10x5 or 15x5. That is, the first size is the width of the bar, and the second is its thickness.

Article on the topic: how to make lighting in the dressing room

Why wood is preferable to metal? As a rule, wooden rafters are easy to install and the quality of such a rafter system will be good. Strength is one of the basic requirements for constructing roofs, and this material is distinguished by the strength and reliability of the structure. In addition, the arrangement of the roof with their own metal-based hands will provide you with considerable troubles. Installation is not easy, there are many nuances, and with the wrong installation will have to redo.

You also need to purchase a good anti-corrosion coating to protect the roof from rusting.

When you do rafters yourself, do not forget that their parameters depend on the roof covering, the length of the rafter and, accordingly, the angle of their conjugation.

Tools for mounting a rafter system

Mounting nodes of the rafter system.

To get started, you should be armed with the necessary tool. For the manufacture of the roof you will need:

- hammers (several varieties);

- nail holder;

- marker for applying marks, pencil;

- ax;

- kerner;

- hacksaw;

- roulette;

- drill.

You still come in handy drill (set), Bulgarian and level. Now that you have purchased all devices and building tools, you can start work. The first stage of mounting the rafter system is to prepare the surface of the wall and overlap. The material on the basis of which the walls are made, it does not always differ in the surface. In any case, there is a discrepancy, even if you visually you will not notice. At the same time, the size of the discrepancy increases with each nearby, and it is not suitable for building a rafter system. To find out the exact discrepancies parameters, you should apply a level or plumb. Thus, you will verify that the walls are really above a few cm, and the angles are far from 90 °. Therefore, before installing the roof, you need to make measurements that will detect discrepancies. Your task is to correct surface irregularities with a special device.

Article on the topic: Balcony glazing options (Photo)

Installation of the rafter system with your own hands

Installation of the rafting roof system.

As a rule, there are many ways to build a rafter system. For example, rafters of hanging structures are installed using finished farms. Specialists recommend to make an attic overlap. What for? The bottom line is that, by collecting the design on Earth, you will be hard to raise it on the roof, as it is too cumbersome. To make the installation, you need to take a ready-made template that is made of lightweight material. You can assemble the rafter farms, they will correspond to these rafted parameters. The main advantages of this method are simplicity of installation and aesthetics. The roof is flat and beautiful.

The rafter to make the inclined design is much easier. However, the template will also be appropriate here, so take care of its creation. Typically, the installation is made by collecting individual elements. Work is performed in several stages.

First you need to set extreme elements, front-line. They should be placed on a plunder and level around the entire perimeter. Next, between them install the twine. His fortress provides a good stretch, which is very important in this work. Then set all the elements, the farm of the rafter system. When the system is installed, make reinforcement racks (swelling), mount the tightening. It is recommended to pull the rafted until the installation of the crate.

So, the rafter system must contain rafting farms, side and skate runs, mauelalat and diagonal elements. Mauerlat is a part of the roofing system, which is a bar or log. Corners are aligned with it.

The main stage in the installation of the roof is the design of farms. It usually includes rafters and farms. Remember that the best variant of the solo system is a triangular design. To do this, you need to apply rafters and a bar (binding). Such a system is the most reliable and durable.

Now you know how the rafting roof system is done with their own hands. In fact, there are no special difficulties in this paper, the main thing is to accurately follow the installation instructions.