A gas-concrete block is a building material with a porous structure. It is produced from cement, water, crushed lime, sand and plaster stone, and aluminum powder is added as a gas-forming component. Aerated concrete is produced only on special equipment in the factory. It is quite possible to build a house from aerated concrete.

Houses from aerated concrete blocks - pluses and cons

Aerated concrete is widely used in various climatic zones in the construction of industrial premises and houses. It has a relatively low weight (less than 30 kg), and 30 bricks can replace 30 bricks. Build a house from aerated concrete blocks and your own hands.

Positive characteristics:

- Thanks to the air-porous structure, the gasoblock has good heat and soundproof properties;

- produced from non-combustible components, fireproof;

- has high frost resistance and long service life;

- on environmental standards, aerated concrete is considered safe material;

- It is not subject to rotting, the formation of mold, as it is made of mineral raw materials;

- It is convenient for processing, it is easy to build a house of any design and make arched door or window loos;

- Due to the low weight, the use of lifting techniques is not required;

- Not subject to destruction from ultraviolet rays and precipitation;

- Heat content - when heated by the Sun, the room inside does not overheat, and in the cold time it does not move;

- Outdoor finish or additional thermal insulation is done depending on the climatic zone and is not mandatory.

The heat-resistant material depends on the wall thickness and the brand of aerated concrete. Thus, the use of the D600 unit with a width of 20 cm has an indicator of 0.71 W / m · K, 30 cm - 0.45 W / m · K, 40 cm - 0.34 W / m · k. If the D400 brand is used: 20 cm - 0.50 W / m · K, 30 cm - 0.31 W / m · K, 40 cm - 0.25 W / m · k.

Negative characteristics:

- hygroscopic - it is not recommended to use blocks for the construction of a sauna, a steam room or a bath without additional vaporizolation;

- Aerated concrete masonry, like any other of a stone material, needs a durable foundation so that deformation does not occur;

- Plaster works are difficult, since the aerated concrete has a smooth surface, which requires adding to the PVA solution;

- For fastening, special fasteners are needed.

With independent construction, the house of aerated concrete can be expanded by architectural plans due to its easy workability. In addition, gas blocks in size are more bricks, therefore, 1 m2 will require no more than 20 minutes.

Set of tools for construction

Before proceeding to the construction of a house of aerated concrete, you should prepare all the necessary tools and building materials. For each construction stage it will be needed:- cord for marking trenches, roulette;

- shovels, scrap, kirk necessary for earthworks;

- Hacksaw for cutting blocks, dosage carriage with glue, scoop, celma, twink, brush, polishing, construction level, rubber hammer, corner. They are used during gasoblock laying;

- Plastering blades and twinks, cuts, rustles, brushes, spatulas, vest - apply for plastering and finishing works;

- Strokesis is designed to dry up the grooves under the laying of reinforcement and wiring;

- Electrical applies to drink deeper grooves;

- Electrode with crown for drilling holes for switches and sockets.

Aerated concrete is well processed by simple tools. As a result, using simple devices, you can quickly and high-qualityly lay blocks. Also with the help of a conventional chisel, you can easily make a decorative finish.

Placement site

Before the start of construction work on the site it is necessary to put the driveway with a large rubble, so that there are no problems with the transportation material and special equipment in the future. The place for the future house is purified by unnecessary materials and garbage.

Article on the topic: Wallpaper Wallpaper Two types: Photo, how to punish different, room options, pasting beautiful, ideas, design stickers, color, examples, video

A plan is drawn up with the boundaries of neighboring sites on which the house and places are planned for economic buildings. With the help of a roulette, peg and cord placed a place under the construction of the building. The pegs are clogged into the ground in the corners of the perimeter, and the rope is stretched between them. The markings for the outer foundation of the house are made by retreating from the stretched cord to the width of the future base, stretch in parallel to his rope. To check the evenness of the perimeter stretch the cords diagonally.

We prepare trenches

In front of the ridge of the trench, it is necessary to determine the type of soil on the place of the future at home. The soil may be very stony, which makes it difficult to ruin the trenches, or vice versa, sandy, then there is a possibility of its squeezing. It should be calculated on which depth and width the trench will be dug. If there are stumps or shrubs with trees that interfere with the construction site, they are uprooted, or move the upcoming build. The removal of a large tree may be very costly and long-term.ROOM trench

You can dig a trench itself - with the help of a shovel, or dig an excavator. When the earth is swollen on the bottom of the ditch, it is cleaned, because even during the coupling it will remain loose. The depth of the trench depends on the level of the freezing, the width is 70-80 cm, or it is equal to the width of the concrete sole (the pit under the monolithic slab). If the soil is loose and appeared, then install shields from boards. At the bottom of the trench make the foundation pillow of sand, thickness 15-20 cm., It is good to tamper.

We do foundation

A tape or monolithic foundation is made under a gas-concrete house. The choice of the desired foundation depends on the technical characteristics of the soil and financial capabilities. The work process can be distributed to the steps:- We make formwork;

- put the reinforcement;

- Pour concrete.

Installing formwork

The formwork is a facility from boards, shields, block elements under the fill of concrete. There are two species: removable - after drying the solution is dismantled, and the unknown - remains as an additional thermal insulation.

The unloading formwork is erected from extruded polystyrene foam, arbolit or ceramzite concrete. Each of the materials has its own both positive and negative properties.

Before laying formwork blocks on the bottom of the trench, the waterproofing material or reinforced film. Work on laying formwork makes from the corner, move around the perimeter, laying them in a checker order. If there are connecting grooves in blocks, then they must be top. Installing the installation is checked on a stretched cord and level.

Stay fittings

Before installing the first row of tape formwork, iron rods fit in the grooves and fasten with a wire. Installed vertical rear reinforcement and attach to horizontal. After the desired height of the formwork is built, the reinforcement is cut off.Fill concrete

The fill of concrete is better in dry and non-fit weather to avoid exemption or evaporation of moisture from the solution. To prepare a concrete solution, it is necessary to use high-quality cement brands M400 or M500. Sand applied without impurities of land and clay, preferably river. Water should be clean, not chlorinated. Large fillers fits crushed stone.

The ratio of cement to the sand - 1: 4, to the rubble - 1: 2, to water - 1: 0.5. If wet sand is used, then the amount of water decreases.

At a minus temperature to eliminate the freezing of the solution, a plasticizer is added. If a small house is built, then it can be used to stir the concrete concrete mixer, and with a larger area of filling the foundation it is better to use the finished concrete mixture. It is necessary in such an area to have enough to fill the entire area at a time. The flooded concrete is necessarily processed by vibrotambovka to remove emptiness and evenly distribute the mixture.

Article on the topic: how to install an overhead lock on a wooden door

We build walls

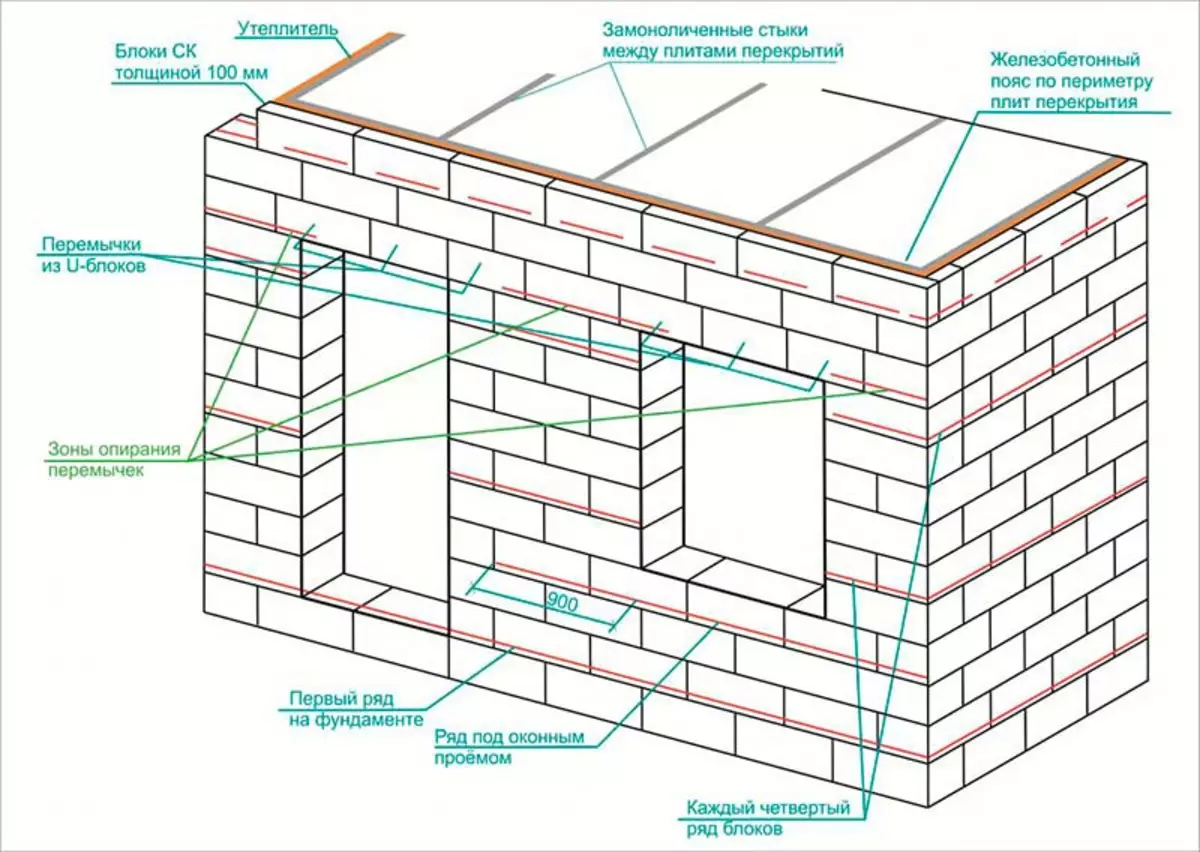

The use of aerated concrete as a material for the construction of the walls allows you to achieve good indicators in strength and thermal building. Blocks are lightweight and have large sizes, which allows you to build the walls of the house with an area of 150-200 m2 only 1-1.5 months. The construction work can be divided into several stages:- lay out the first row;

- put the 2nd and 3rd rows;

- Preparation for window sills and windows;

- jumpers on windows and window sills;

- Armopoyas inter-storey.

We put the first row

We remove garbage, dust and water waterproofing from the top of the foundation. We laid it throughout the perimeter and domestic walls. To lay insulation is better not docile, but a mustle.

For the calculation of the first row, cement mortar is used, since the top of the foundation does not happen quite smooth. The use of the mixture will help align all the irregularities, smoothly lay fuel-concrete blocks.

The minimum thickness of the cement mortar layer is 1 cm, so it is necessary to determine the highest angle on the foundation using the level. From him and begin to lay gas blocks, constantly referring to level testimony. Do it after each laid block.

The masonry is carried out throughout the perimeter of the house and on the walls inside it, not forgetting to adjust even the level. It is convenient to use gas blocks with fastening "groove-ridge" - they are easier to put and transfer them. Also for convenience and saving time pallets with blocks are placed inside the construction.

Make the 2nd and 3rd rows

Before laying a new row of gas blocks, the surface of the previous one must be polished with polishing. This is done for a better adhesion of glue between blocks, as it is applied in just 0.5-0.7 cm.

The second row is laid from an angle with a shift on a half block (at least 8 cm) so that the seam from the laid gasoblocks does not coincide with the previous ranks. The glue is applied using a dosage carriage or a special bucket with cloths. Gas blocks are put as close as possible to each other, if necessary, use a rubber hammer. Work should be done as quickly as possible, as the glue is seized after 15 minutes. At a minus temperature to -15 ° C use glue with special additives.

Also put blocks of the third and subsequent rows. It is necessary to regularly monitor the evenness of the laid gas blocks. Decavoring aerated concrete to the place of future doors or windows, it is not always possible to put them so that they do not speak in the pereg. With this problem, it is easy to cope with the help of an ordinary hacksaw with long teeth. For smooth sleep, a special corner is used.

Preparation of walls under the windowsill and windows

Doing the reinforcement of window openings need one row below the future windowsill. It is necessary to strengthen the walls where the window will be. For this, there are 2 longitudinal grooves along the length of the wall. The furrows should be greater on each side by 30 cm windows width. The reinforcement is stacked and poured with cement mortar. Further installation of aerated concrete blocks is done on glue, in the right order, taking into account window and doorways.Making jumpers for windows and doors

Over the door and window processes it is necessary to install jumpers so that wall collapsing occurred. You can do this in several ways:

- A simple option is to purchase ready.

- U-shaped aerated concrete blocks can be used. Over the door or window opening is made from the backup board. The required number of U-shaped gasoblocks glue together and laid into the desired location. Inside the blocks are placed on the reinforcement and poured with cement mortar.

- Simple fuel-concrete blocks glue and stroke 3 longitudinal furrows in them. Put the reinforcement and poured the cement-sandy mixture. They give dry about 24 hours. They put such jumpers on the outlook not wider than 1 meter and the reinforcement down.

The gaps between the wall and jumpers are laid by gas blocks of the desired dimensions.

Armopoyas Marketing

Armopois is a layer of reinforced concrete, filled between blocks. We are necessary to impart the strength of the entire wall design and installation of Mauerlat.

Article on the topic: Curtains in the bedroom interior: color, design, species, fabric, styles, 90 photos

On the edges of the outer walls, gas blocks are put, 10 cm wide, forming a formwork. In the resulting space between blocks fit the reinforcement and poured with a solution.

For mounting Mauerlat in Armopoyas vertically concrete reinforcement rods with thread sliced on them. Studs are set at a distance of 1-1.5 m from each other.

Roof

On armopoyas walls, the waterproofing material is spilled and Mauerlat (support timber) is stacked. It is attached to the hairpins with nuts. At the corners of the design, the support bars fasten with steel brackets. A tightening is done, that is, in the width of the construction stacked the transverse bars. Further along the length of the house, 2 rows of Bruusyev (Lezhenny) are fixed so that they are at the same distance from each other and from the edges. For example, if the width of the house is 10 m, then this distance will be 3.3 m.

On the layers with the help of brackets, corners or nails are mounted vertical wooden racks at a distance of 2-2.5 m. They are installed opposite each other on both sides. For better bond, over the racks parallel to the width of the roof are tightened. Then stacked on the wooden rack from both sides along the roof length of the longitudinal beams - run. They are needed for support rafters.

The installation of the rafter starts from the edge of the roof, making an equal distance between them. The lower part of them is fixed to Mauerlat, and the top is attached to standing opposite the rapid bruus. For the strength of the entire attic construction of the rafters, fasten with running bars.

Before laying a roofing material, a doomle is made. It is rooted on it, making it right left and bottom-up. For each type of material requires their fasteners.

Finishing work

Fuel dispense walls are leaving siding or sandwich panels. When they are installed, it is necessary to leave the gap between gas blocks and finishing materials. It is needed to remove moisture that can get through various slots.The interior decoration of walls from aerated concrete is carried out at a temperature not lower than + 10 ° C. If there are chips, shot down edges, holes on the surface of the blocks, they are filled with a masonry mixture. The protruding parts on the walls are rubbed with a grinding cooker.

Inside, aerated concrete walls are separated by plaster or plasterboard. After that, they can be painted, wicked or lined with other materials.

Plastering the walls with a special mixture for gas-blocks, which is bred in accordance with the manufacturer's instructions.

Approximate estimate for construction

The construction of the house begins with the creation of a project and work to determine the characteristics of the soil. The cost depends on the rates of organizations.

Further determine the cost of manufacturing the foundation. For a house of 10 × 10 m in size:

- Monolithic base (stove) - 500-700 thousand rubles;

- Ribbon - 300-500 thousand rubles.

If you do a monolithic foundation yourself, the price will be almost half less.

At the cost of blocks in 3 thousand rubles. For M3, 210 thousand rubles should be spent on the construction of all walls. For masonry, about 105 bags of glue will also need. The average value of one is 250 p. Total amount - 250 × 105 = 26250 rubles. Armature is added here. It will be needed with a stock of about 1 km, and it will cost 15 thousand rubles. Armopois will cost 75 thousand rubles.

The cost of overlappings depends on the type of material. It starts from 50 thousand rubles. The roof price also changes from filling. The arrangement of the rafting system costs about 100 thousand, roofing coatings start from 70 thousand, insulation of mineral wool - 20-50 thousand rubles. The house of aerated concrete without decoration, an area of 100 m2, built by their own hands, will cost about 1 million 200 thousand rubles.