The beautiful and functional floor in a private house or apartment plays a big role in the interior design. A qualitatively designed base allows you to create comfort and comfort. Recently, many developers to create a finishing flooring use laminate.

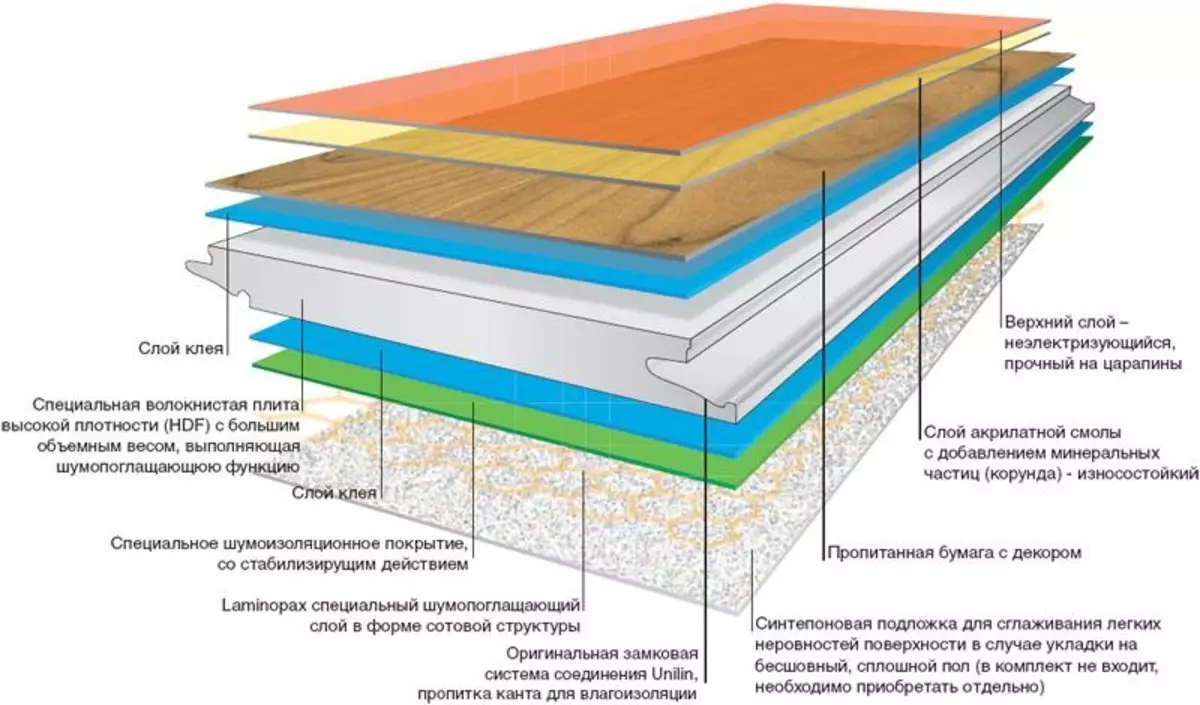

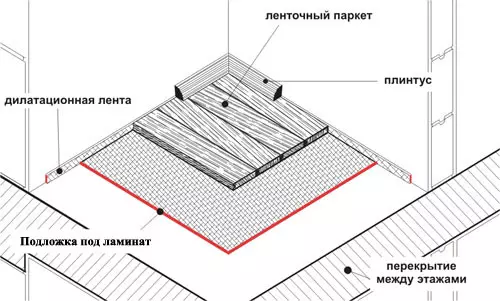

Laminate device diagram.

During the work, you may need various tools and materials. Therefore, it will be further discussed that it is necessary to lay this material.

What do you need to know before laying a laminate?

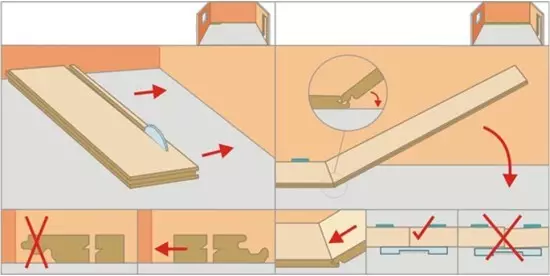

Laminate laying scheme.

If you install this floor covering for the first time, before it should be understood in some important points, subject to which the floor will be able to serve you not one year:

- After purchasing panels, it is necessary to carefully check each element for the possible damage. It is not recommended to carry out the material that even the slightest defects.

- When conducting construction work, the humidity in the room must comply with certain criteria. It is impossible to enter the laminated water coating or other liquid.

- Before laying a laminate, it is necessary to make its excerpt in the room in which it will be mounted, at least 48 hours at temperatures above 18 ° C. In this case, the humidity should be 50-65%.

- To hide the slots arising between the adjacent panels, without the use of additional decorative elements, laying the laminate should be carried out in parallel with the sunshine.

What does the developer need to lay a laminate?

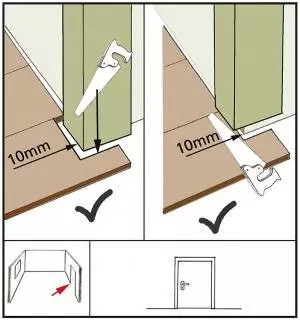

Laying of laminate at the doorway.

To carry out installation works, you must prepare the tools with which the entire process of laying will pass without any difficulties, namely:

- manual saw or grinder, which will allow to trim unnecessary parts of the panels;

- Hammer used to bother board: For these purposes, it is recommended to buy a special hammer that will eliminate possible damage to the laminate during a shotgun, if there is no such possibility, you can wrap the tip of the usual hammer with a rag;

- nails and threads, with which you can draw a parallel with parallel laying or diagonal with a diagonal installation method;

- the level that allows you to check the fatality of the base before carrying out installation work;

- Pencil and line used for measurement and lines, for example, if necessary, trim a specific part of the panel;

- wedges that are inserted between the wall and the coating to create a certain gap in accordance with the laying technology;

- Clamps that are wound up extreme elements of the floor covering.

Article on the topic: Batteries for the gas column

From materials that are used to lay laminate and its subsequent processing, you need to cook:

- insulating substrate;

- laminated panels;

- polyethylene film;

- Adhesive composition.

Next, these materials will be considered in more detail.

What should I use the substrate?

The substrate helps not only make the base to more even, but also protect the laminate from the harmful effects of moisture, temperature drops and noise.

Today there are several types of substrates:

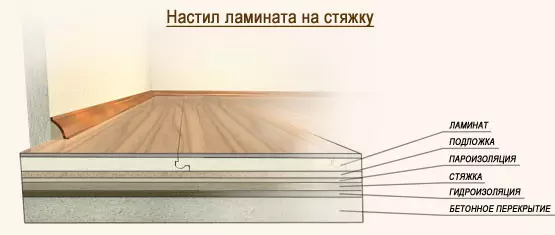

Laminate flooring on the screed.

- The substrate of foamed polyethylene is the most popular insulating material that has such advantages: excellent heat and noise insulating properties, moisture resistance, protection against rotting. Due to its elasticity and lightness, this material is very convenient in operation and is easily processed. In the manufacture of such a substrate, only high-quality materials are used that do not enter the chemical reaction, so it can be used with construction materials such as cement, concrete, lime, plaster and wood.

- The extruded polystyrene substrate has a good resistance to increased pressure, has excellent sound and thermal insulation properties, has a large operational period.

- The cork substrate is made of cortex cortex. Among the main advantages of this material is to highlight: naturalness and environmental purity; excellent sound, heat and waterproofing; the ability to use under any coating; allows you to protect the laminate from the occurrence of mold and fungus; With it, you can hide small irregularities of the foundation.

- Polystyrene substrate in the form of granules between two layers of polyethylene also relates to high-quality insulating materials. The main advantage is in the ability to remove moisture through the side gaps, which are placed around the perimeter of the room.

The installation of the substrate is quite simple, which does not require any special skills and skills. Before starting work, it is necessary to clean the base from dust and dirt, and then process it with primer. After the primer dries, laying the insulating material is made, after which its edges are glued with a wide scotch. At the same time, the distance between the wall and its edge should be at least 10 mm.

Article on the topic: Reinforcing mesh for a screed, applying the reinforcing grid. How to organize a screed and reinforcement?

What laminate to choose for floor laying?

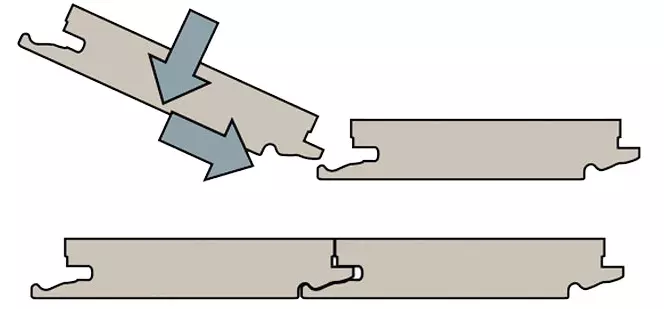

Scheme of a unique castle connection.

Buying this building material, it is necessary to take into account the main purpose of the premises in which it will be mounted. Based on the degree of loads that the floor covering will distinguish the laminated panels for domestic and commercial use.

The quality assessment of the laminate is carried out on the basis of such indicators:

- erased;

- sound insulation;

- impact resistance;

- water resistance;

- Stability to mechanical damage.

The main test that the panel can be called is called a table test, it is carried out with the help of a grinding circle. With it, the number of circle revolutions is calculated before the top layer of laminate starts to stick. In the current market of building materials, laminated floors may have a wear resistance in 7, 9, 11, 15, 17 and 24 thousand revolutions. The more this value, the better the material will be and the price will be more.

Floor Device Scheme.

In household premises, laminate is mounted in such classes:

- 21 - Used for buildings with a small intensity of walking (for example, bedroom);

- 22 - stands in rooms with the average intensity of walking (children);

- 23 - Mounted indoors with a large intensity of walking (kitchen, hallway).

The above types are designed for domestic use. For commercial purposes, the following types of laminate are used: 31, 32 and 33, which are mounted for premises with a small, medium and increased intensity of walking, respectively. The only difference of these species from domestic laminate is their increased service life.

Polyethylene film and glue for laminate laying

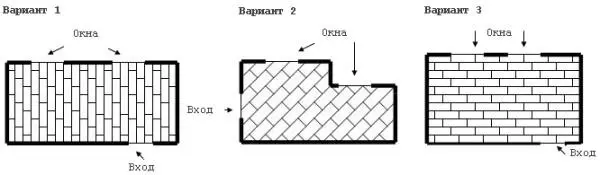

Laminate laying methods.

Polyethylene film is one of the most common and unique polymeric materials. It allows you to ensure excellent coating moisture proof. As a rule, it is placed in a solid layer with a thickness of about 0.2 mm on a dry mineral surface. This measure prevents the penetration of residual moisture inside the laminated panel below.

Article on the topic: Smooth and Relief Flizelin Wallpaper

In its composition, glue for laying laminate can be divided into:

- water-dispersive;

- Composition based on synthetic resins;

- two-component polyurethane glue;

- One-component composition.

The selection of one or another adhesive composition should be carried out after familiarization with its properties and characteristics.

For laying the laminate, it is forbidden to use PVA glue, because it is made on a water basis, which can lead to floors.

The glue composition for laying laminate must have the following characteristics:

- to be resistant to the influence of moisture, this criterion is the main one;

- have excellent adhesion, which allows you to get reliable and high-quality coverage;

- be resistant to low temperatures;

- Environmental safety: It is important that the adhesive does not include volatile essential compounds, dangerous for human health;

- The remnants of the adhesive mixture should not be left on the coating of spots and drills.

Before applying any adhesive mixture, the laminate must be cleaned of dust and dirt, after which degreasing it with special substances.

If only qualitative materials were used when designing a laminated flooring, only qualitative materials without disrupting work technology were used, then you can be sure that such a floor will be high-quality and reliable, as well as to have a large operational period.