The creation of the heating system involves the connection of the boiler and heating devices (radiators, convectors and warm water floors). Also, the system must contain devices that provide security. The procedure for connecting the entire farm and is called the "boiler".

What is a blockage and what makes it

In the heating system, two main parts are boiler and heating radiators or a warm floor. What binds them and ensures security is the binding. Depending on the type of the installed boiler, different elements are used, therefore, it is usually considered separately the strapping of solid fuel units without automation and automated (more often - gas) boilers. They have different algorithms of work, basic - the possibility of heating a TT boiler in the active burning phase to high temperatures and the presence / absence of automation. This imposes a number of restrictions and additional requirements that you have to perform during the strapping of a hard fuel boiler.

Example of the strapping of the boiler - first goes copper, then - polymer pipes

What should be in the strapping

To ensure the safe operation of heating, the boiler should contain a number of devices. Be sure to be:

- Manometer. To control pressure in the system.

- Automatic air vent. To descend the air that has fallen into the system - so that the traffic jams are not formed and the movement of the coolant was not stopped.

- Emergency valve. To reset the excessive pressure (connects to the sewage system, since a certain amount of heat carrier is blended).

- Expansion tank. We are needed to compensate for thermal expansion. In open-type systems, the tank is placed at the upper point of the system and is a conventional container. In closed heating systems (mandatory with circulating pump), a membrane tank is put. Installation location - in the return pipe, before entering the boiler. It can be inside a wall gas boiler or installed separately. When using a boiler for water preparation for DHW, an expansion tank is also needed in this circuit.

- Circulation pump. Mandatory to install in systems with forced circulation. To increase the efficiency of heating can be both in systems with natural circulation (gravitational). It is put on the feed or reverse before the boiler until the first branch.

Approximate blocking of floor boiler

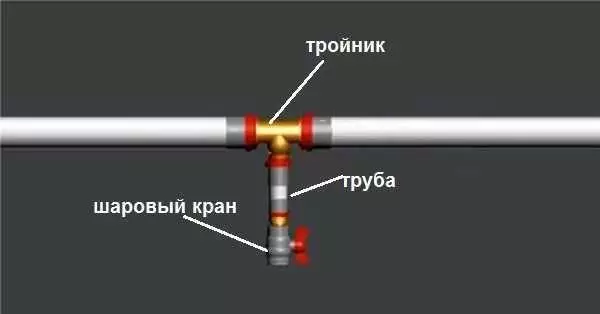

Some of these devices are already installed under the casing of the gas wall boiler. The blockage of such an aggregate is very simple. In order not to complicate the system with a large number of taps, the pressure gauge, the air vent and the emergency valve are collected in one group. There is a special case with three taps. Related devices are screwed on it.

So the security group looks like

Install the security group on the supply pipe immediately at the outlet of the boiler. Put so that it is easy to control the pressure and it was possible to manually inspire pressure if necessary.

What pipes do

Today, metal pipes are rarely used in the heating system. They are increasingly replaced by polypropylene or metalplastic. The binding of the gas boiler or any other automated (pellet, on liquid fuel, electric) is possible at once with these types of pipes.

Wall-mounted gas boiler can be connected by polypropylene tubes immediately from the input of the boiler.

When connecting a solid fuel boiler, at least a meter of the pipe on the supply is impassable to do with a metal pipe and is best copper. Then you can put a transition to metal plastic or polypropylene. But this is not a guarantee that polypropylene will not collapse. It is best to make additional protection against overheating (boiling) TT boiler.

Which of polymer pipes are better? Polypropylene or metal-plastic? There is no definite answer. The blockage of polypropylene is good for the reliability of the compounds - properly welded pipes are a monolith. (How to connect polypropylene pipes here). But the maximum allowable temperature of the coolant in the system is not higher than 80-90 ° C (depending on the type of pipe). And that, the prolonged exposure to high temperatures leads to rapid destruction of polypropylene - it becomes fragile. Therefore, the strapping of the boiler by polypropylene is made only in low-temperature systems based on automated boilers.

In the presence of protection against overheating, the strapping of the boiler can be made by polyropylene tubes

Metal plastic has a higher operating temperature - up to 95 ° C, which is enough for most systems. You can make both the strapping of a solid fuel boiler, but only in the case of the presence of one of the protection against coolant overheating systems (described slightly below). But metal-plastic pipes have two significant drawbacks: a narrowing of the connection site (fittings design) and the need to regularly check compounds, as they flow over time. So the strapping of the boiler with metal-plastic is made under the condition of use as a coolant of water. Immediate fluids are more flowable, because in such systems, crimp fittings are better not to use - they will still flow. Even if we replace the gaskets are chemically resistant.

Bind of gas boilers

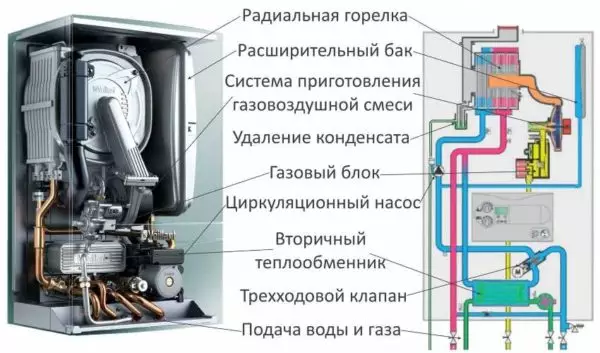

Modern gas boilers have a good automation that controls all the parameters of the equipment: gas pressure, the presence of a flame on the burner, the level of pressure and the temperature of the coolant in the heating system. There is even an automation that can adjust the work under the weather. In addition, wall gas boilers in most cases contain such necessary devices as:

- security group (pressure gauge, air boom valve, emergency valve);

- expansion tank;

- circulation pump.

In the wall gas boilers, the expansion membrane tank and the security group already installed

The parameters of all these devices are indicated in the technical data of gas cats. When choosing a model, you need to pay attention to them and choose a model not only by power, but also by volume of the expansion tank and the maximum volume of the coolant.

Wall gas boiler strapping scheme

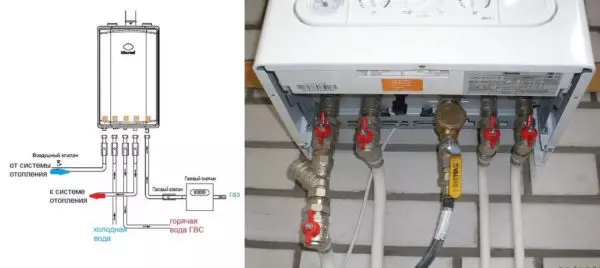

In the simplest case, the boiler's strapping contains only shut-off cranes at the inlet of the boiler - so that it is possible to carry out repair work if necessary. More on the return pipe, coming from the heating system, they put a filter-mud - to remove possible contaminants. That's all the binding.

An example of a wall-mounted gas boiler strapping (dual circuit)

In the photo above there are angular ball valves, but this is how you understand, it is not necessary - it is quite possible to put ordinary models, and the pipes unfold closer to the wall with the help of the corners. Also note that from both sides of the mud face cranes are in order to be able to remove it and clean without draining the system.

In the case of connecting a single-circuit wall gas boiler, it is still easier - only gas is applied (gas supplies are connected), the supply of hot water to radiators or water heat and the return on them.

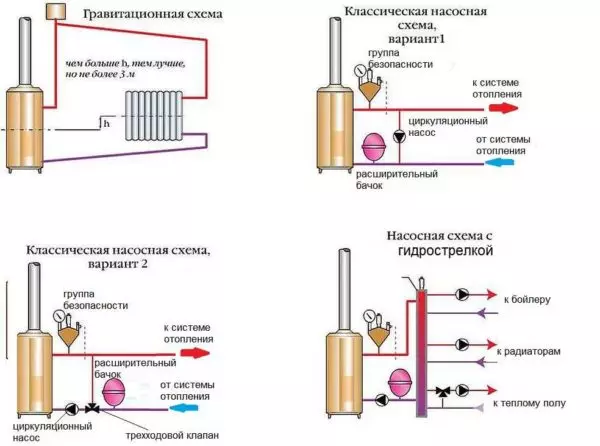

Schemes of the strapping of floor gas boilers

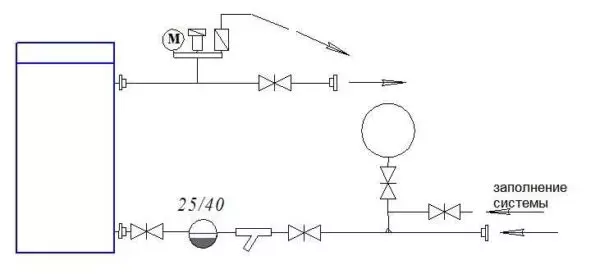

Outdoor models of gas heating boilers are also equipped with automation, but do not have a security group nor an expansion tank, nor the circulation pump. All these devices have to be installed additionally. The scheme of the strapping because of this looks a bit more complicated.

Outdoor gas boiler strapping scheme

On two schemes of classical strapping of the boiler installed an additional jumper. This is the so-called "anti-condense" loop. It is needed in large systems if the water temperature in the return pipe is too low, it can cause condensate formation. To eliminate this phenomenon and arrange this jumper. With its help, hot water from the supply is mixed to the reverse pipeline, the temperature above the dew point (usually 40 ° C). There are two main ways to implement:

- With the installation in the jumper of the circulation pump with a remote temperature sensor (and the photo at the top of the right);

- Using the three-way valve (in the photo below left).

In the circuit with a circulation on the jumper (condensation pump), it makes a pipe on a step of smaller diameter than the highway. The sensor is attached to the feed pipe. When the temperature decreases, the pump power supply circuit is turned on, hot water is added. When the temperature becomes above the threshold, the pump is turned off. The second pump is the heating system itself, it works all the time while the boiler works.

In the second scheme with a three-way valve, it opens up hot water to lowered temperatures (exhibited on the valve). The pump in this case is on the return pipeline.

Cutting a solid fuel boiler

Any owner of TT Boiler knows that during the active burning phase there is a lot of heat. Since its experience comes from time to time - when and how to cover the damper, at what time interval, etc. But it is worth a little distract, and the water in the system will overheat and can even boil. To prevent such a phenomenon, the strapping of the boiler without automation should contain several devices that prevent the boiling system. Only in this case can be wiring through the house to make polymer pipes. Otherwise, sooner or later, the superheated heat carrier softens the material, the pipes will break through with all the ensuing consequences. Therefore, the blockage of a solid fuel boiler In addition to traditional elements - security groups, expansion tank and circulation pump - contains a solid number of additional devices and usually requires rather solid funds.

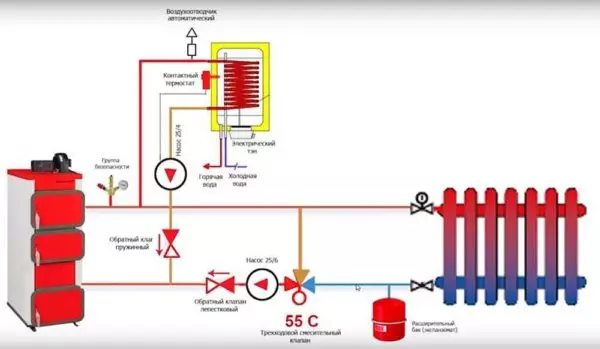

One of the simple straps of a solid fuel boiler

The cyclic nature of the work of boilers on solid fuel leads not only to the boiling system, but also to the fact that it is very hot in the house (when the fuel is actively burning), then cold - when everything burned. To eliminate these phenomena there is a solution: to establish an indirect heating boiler or a heat accelerator. Both are water tanks, they simply perform different functions and, accordingly, are connected in different ways.

Distribution with an indirect heating boiler

The boiler of indirect heating warms the water for the DHW and connects on one side to the heating system, and on the other - to the comb of hot water distribution. Thus, the temperature differences are softened, and water is heated for technical needs. A good solution.

Schema of the strapping of a solid fuel boiler with an indirect heating boiler

How does this scheme work? If the temperature of the water in the water heater is below the specified, the boiler connects to the heat of water in the tank. The heating system at this time turns out to be disconnected and cool down slightly. After the water heating to the required temperature, the boiler switches to work with the heating circuit. When warm water is spent, the temperature in the tank falls again, the connection is connected again for heating.

It is easy, but with such a scheme, overheating is still possible - not always the consumption of hot water coincides with the phase of active burning of fuel. In this case, overheating is possible.

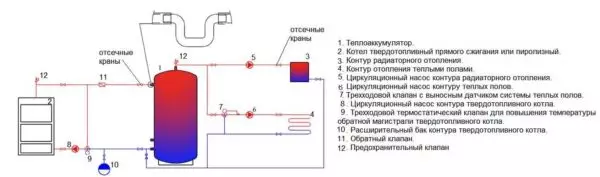

Scheme with heat accumulator

The second way is to establish a heat accelerator. This is also a water container, but it is connected only to the heating system. Used to mitigate the temperature differences in the system.

This method is more reliable, but requires a device of several separate contours. The boiler warms the water in the heat accumulator - it is connected to the entrances of that. This is one closed outline. The second outline goes to heating - from the exit of the heat accumulator (in the upper part of the tank), hot water enters the heating system, and the cooled water from the reverse pipeline enters the lower part of the same tank. If necessary, you can connect the water warm floor system.

Scheme of strapping TT boiler with heat accumulator

With such a construction, there is no usual for a solid fuel boiler a sharp increase in temperature during active burning. All because the volume of the tank is added, therefore the overheating of the water is practically no happening. Then, when the fuel burned down and in the usual system, the house begins to cool, the heat in the heating phase continues to be spent in the system. In this way, the temperature background is aligned and the time between the firebox increases.

Such a lining of the boiler on solid fuel is more reliable and the wiring from that can be made by polypropylene tubes, but the contour from the boiler to the tank must be made by metal pipes. In this case, it is possible to use steel, but better after all copper.

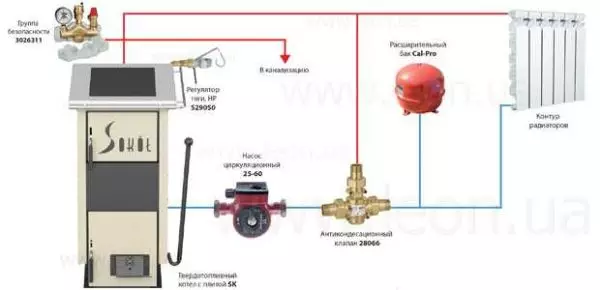

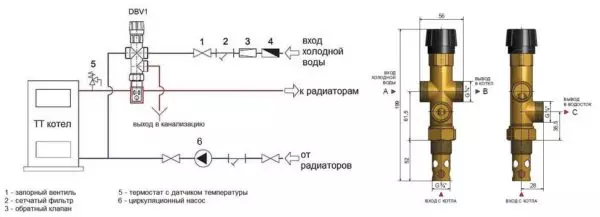

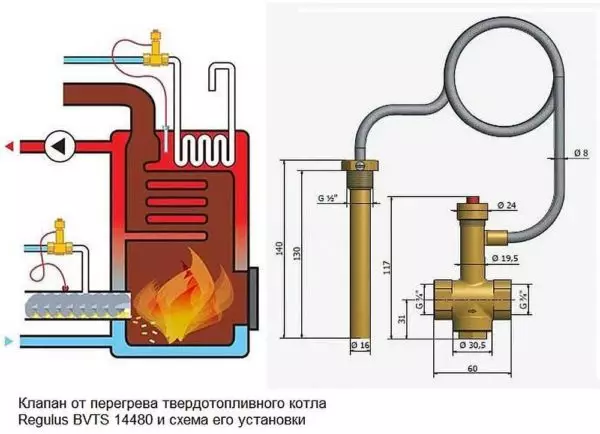

Venting TT boiler with overheating valve

The third way to protect against overheating of a solid fuel boiler is to establish an automatic overheating device. This is a special valve with a temperature sensor. The principle of operation is simple: when a certain temperature is exceeded (usually 95-97 ° C), the valve opens the inlet of cold water from the water pipeline, and overheated overheated to the sewer. So works, for example, REGULUS DBV 1-02, REGULUS BVTS 14480.

Protection of solid fuel boiler from overheating using valve regulus DBV

Valve although they are manufactured by one company, have a different structure and installation scheme. So REGULUS DBV is installed at the outlet of the boiler, has a built-in temperature sensor (installation scheme - above). The overheating valve of the overheating TT boiler Regulus BVTS 14480 has a remote sensor, can be mounted both at the input and at the output (installation scheme at the bottom). What is good this option? The fact that it can work in systems with natural circulation - it does not need pressure for work.

Recovering the heating boiler with the protection valve from the boiling of heat carrier

Their estimated cost is 40-60 € - it is much smaller than the cost of mounting the heat accumulator or the boiler of indirect heating, but this method does not solve the problem of fluctuations. These valves, by the way, can be used to improve the reliability of the circuit with the established indirence and the accurate to eliminate the possibility of boiling the system.

What else is needed in the system

The binding of the boiler will be incomplete if there is no crane for draining and filling the system. And better if they are separate. The specific installation site depends on the structure of the system, but there are certain rules:

- Crane for plum makes at the lowest point. This is very important if the heating system needs to be preserved for the winter - it is necessary that it remains as little as possible coolant. If the system will work in winter, it is always possible to use a crane (with or without or without a nozzle) to one of the radiators, it will be a suspension of the system.

Such a crane for a drain system can be installed in any convenient place (on the return pipe)

- If water is used in the heating system, the input from the water supply is usually connected. In the case of a wall-mounted gas boiler for this there is a special nozzle with a stationary crane. Cold water is connected to this entry, if necessary, the faucet is discovered for a short time. If the boiler is used without a special nozzle, in the feed pipe (preferably higher) also set the crane. As an option - on the segment of the pipe that goes to the expansion tank.

One of the options for installing the crane to fill the heating system

In some systems, the plums and the bay of the system are made from one crane. This is possible if there is a pump, which pumps the coolant and there is a pressure gauge, which can be controlled by the pressure being created. If there is a separate crane for the bay of the system at a high point, you can fill it with gravity.

Article on the topic: Choose fashionable wallpapers for the 2019 hall: photos and 7 varieties