The warm floor is a special system that provides heating and comfort in the house. The basis of such a system is the installation of special electrical heating cables or pipes with a coolant, which are poured by a cement screed after inspection of performance.

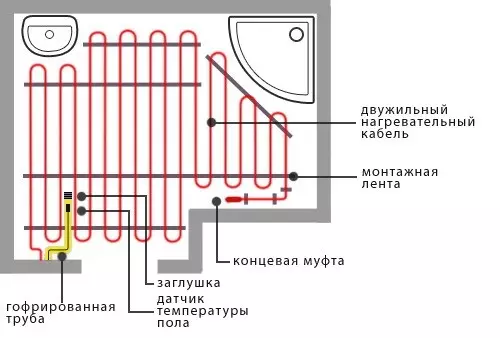

Scheme for mounting electric heating floor.

Pour the floor with your own hands is not as difficult, but it is necessary to accurately comply with all the features of this process, choose a high-quality mixture for fill. Most often an ordinary cement solution is applied, it is laid out in 2 layers - black preparatory and finishing, which is filled after installing the system and its connection.

Warm

Before pouring a warm floor, you must immediately determine how many layers are necessary. It all depends on what state is the base base. Sometimes it is required to provide a rough screed. The thickness of such a layer is only up to 5 cm, the fill itself is necessary in order to align the surface, make it suitable for installing the heating system.

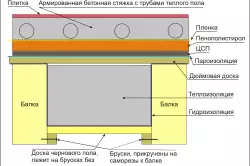

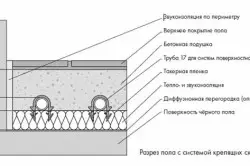

Warm floor diagram with concrete tie.

The second layer of fill is called chistov. It is a thicker screed, which is poured directly to the mounted heating system and is the basis for laying the flooring. The thickness of this layer is greater, it can reach 10 cm, but attention should be paid to choosing a mixture and how heat will be distributed.

Typically, the manufacturers of warm sex systems provide recommendations on the thickness of the screed, since too thin or thick layer will be bad and keep warm. In the first case, the system can be accidentally damaged.

You can use for the fill with a conventional concrete mixture or use semi-dry, which is characterized by quality. It is practical more convenient. Water is required for it much less, and the speed of frozen is fast. The strength of the resulting fill is high.

Not only concrete and explorer, but also fibrovolok, polymers, allowing the work simple and fast, is part of the semi-shrew. The process of laying is no different from the usual, the mixture is exactly distributed over the surface, aligned. Lighthouses and markup are used for work, and the walls around the perimeter must be separated by a damper ribbon.

Article on the topic: Installation of window blocks: Tools, materials, preparation of the opening and installation

Chernovaya Fill and Her features

Schemes of screed.To pour the floor with your own hands, you must first perform a rough finish, i.e. Fill the first leveling layer. This will make the floor not only smooth and suitable for installing heating system, but also provide the necessary conditions for its hardness. Before starting the draft fill, you need to fly the walls around the perimeter, install a special damper tape.

Pouring is performed by a layer of 5 cm maximum, but the floor should turn out perfectly smooth. For this, markup and special lighthouses are applied. You can immediately carry out work on the insulation of the base and its waterproofing, everything depends on the characteristics of the base floor. For the pouring, an ordinary cement-sand mixture is used, but you can buy special semi-dry couplers in stores that have excellent qualities.

Beton for finishing

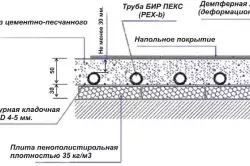

The pure fill of the warm floor is carried out when the system is verified, and for water floors, the coolant is also required. At the finishing fill, special temperature gaps are envisaged, but it is only required for large rooms. Seam is not so difficult, you only need to cut the grooves to a depth of 3-4 cm . This can be done with a diamond disk. The resulting slot is stacked by foam - foamed polyethylene, after which the seam above is closed with a silicone-based sealant.

The pure fill of the warm floor is carried out by a concrete mixture, it must meet all density requirements. It is important to choose the brand of concrete to work correctly, in this case only M150-300 is suitable. At the same time, M150 is used for residential premises, and M300 - for industrial.

Floor screed fixtures.

Many believe that the additives for the mixture will help increase the strength, improve the characteristics, but in fact, such ingredients are not always needed for the fill of the warm floor. Without them, it is quite possible to do, it will save on the tie device, but it will not affect quality. Pouring can be made of cement-sandy composition, but this option is not the best.

For finishing fill, it is best to apply a special concrete with a small screening, it turns out much stronger and more durable, the floor after drying is not cracking.

Article on the topic: Flooring knot for a warm floor with your own hands

To pour the floor, it is necessary to use special compositions for the preparation of the mixture:

- Open-up concrete solution: 1 part of cement on 6 parts of cooked rubble drops.

- Concrete solution based on rubble and sand. To do this, you need to take 1 part of the cement, 3.5 parts of sainted sand, 4 parts of rubble.

You can use ready-made mixtures that are sold in a dry form, they are simply pouring them enough. A building mixer is used to stirring, plasticizers are included in the composition to facilitate the stirring.

Floor fill conditions

Pouring water warm floor.

For a warm floor, the fill is performed in compliance with certain conditions that have a certain impact on quality. For the black first fill, the thickness of the screed should be up to 5 cm. This is enough to ensure the alignment of the floor, the necessary strength of the heating system itself.

For finishing finish fill, the thickness can already be completely different, usually it corresponds to 5-10 cm. Parameters depend on the purpose of the room. For example, for residential premises, 5-7 cm is enough, but for industrial facilities, where the load on the system will be large, the fill thickness requires 10 cm.

When performing such work it is necessary to remember that the proper heat distribution is important for the underfloor, accumulation, i.e. Saving for quite a long time. Too thin layer is unfavorable.

Saving on a concrete solution, you can only get high heating costs, since the heat of such a floor will keep badly, the system will have to be included much more often, and the energy consumption for it will increase.

It is impossible to do too thick layer of fill, as it will take more time for heating, and the surface itself will warm up not so good. Specialists for warm sex are advised to observe the optimal value of 5-8 cm.

It is important during the work not to forget about external conditions. For example, the temperature should only be the plus. In no case cannot be launched at minus temperatures, even if you plan to use additives and other additives.

When you can not spend the screed?

Scheme of a warm floor with a system of fastening brackets.

While working on a warm floor device, you must carefully ensure that all steps are respected in the order that is necessary. It is impossible to start pouring the surface of the floor in such cases:

- If there are no markups on the walls, according to which the thickness of the screed is adjusted.

- In the absence of a damper tape or if it is posted extremely poorly, lagging behind the surface of the walls, has breaks.

- You can not pour the finishing layer before the performance of the entire system is not checked, since it will not be possible to correct the problems. You will have to remove all concrete coating and perform the screed again.

- It is impossible to fill the water warm floor if the water in the pipe is not running, as the weight of the concrete is simply a doubt.

Article on the topic: how to make the shelves on the loggia and the balcony

General conclusions on the warm floor

To correctly pour a warm floor, you need to perform such simple rules:

Warm floor laying schemes.

- First, all plaster works are required. When the plaster is dry, you can start working on the pouring screed.

- A damper ribbon is necessarily attached to the walls around the perimeter of the floor, it will help to avoid many troubles at a temperature expansion.

- It is impossible to start the fill before the markup will be performed and the lighthouses are not installed. Only when using them, the floor will be perfectly smooth and beautiful, suitable for the installation of the heating system itself and for laying outdoor decorative coating.

- It is important to make a mixture properly for filling. Even if a ready-made dry mixture is used, which is divorced by water, it is required to accurately comply with all the proportions, since the strength, the reliability of the floor, its durability, the correct distribution of heat depends on this. The same applies to the fill itself. The use of warm floors will not be effective if the layer do too thick or thin, in the latter case there is a risk of damaging the system.

- If the area is large, then it is necessary to arrange special temperature seams on the surface.

For filling of a warm floor, you can use a variety of cement-based mixtures. This can already be a ready-made dry mixture, which is simply divorced by water, a solution that is sacrificed independently from the necessary ingredients (cement, sand, gravel, and so on). You can apply special semihow ties that are distinguished by high quality. During the use of the fill, it is necessary to clearly follow all the requirements and stages, attention to the observance of proportions.