By its structure, a plasterboard sheet is a rectangular design consisting of a gypsum core, covered on both sides by cardboard. Plasterboard refers to the category of environmentally friendly materials, has good performance, due to which is actively used in "dry construction".

The structure of the leaf of plasterboard: 1- Gypsum base, 2 - sheets of plasterboard.

Thanks to clear geometric sizes, calculate the flow rate of plasterboard per square meter is completely simple. When choosing a material, it is necessary to take into account its purpose for installation under certain conditions.

Of the total mass of this material, the loss of gypsum "gets" 93%, the cardboard takes 6%, another 1% remains on starch, moisture. In the design of the plasterboard sheet, only cardboard is amenable to fire. And that, due to the lack of an air layer between cardboard and plaster, paper does not burn, but tweet. Certain types of sheets have good flexibility; Plasterboard can be a soundproofing material under the condition of appropriate frameworking, proper sealing of seams with high-quality putty. The consumption of building materials when using drywall is associated with its type and application technology. Today, the products of the two largest producers are mainly used, each of which uses its markings to indicate the type of material.

Classification by "Knauf"

Classification of drywall and standard sizes of sheets by Knauf.

- GLC This is a rectangular "piece" of gypsum, from 4 sides by cardboard.

- G Clac. Moisture-resistant plasterboard intended for use in rooms with high humidity. The cardboard used in production is processed, which reduces the possibility of forming mold, fungi and other similar microorganisms. So that you can distinguish moisture-resistant material from the usual, the Cardboard of green is used for pasting.

- GKLO. This plasterboard has increased resistance to high temperatures. Used where there are high safety requirements in the fire plan.

- Globo. Fire-resistant material and at the same time having increased resistance to moisture penetration.

- GVL. Gypsumless sheet, which is a pressed non-combustible mixture of crushed paper and plaster.

- GVLV. Plasterboard with an increased resistance to moisture.

Article on the topic: How to plaster slopes: do it right

The first four types of plasterboard sheets are actively used in construction when frameing frame partitions, wall cladding, ceiling fusion. G Clac can be used as an additional insulation. The two recent types of drywall from the above list use:

- in basements where humidity exceeds 70% (for the flooring of the floor, walls with subsequent laying of tile);

- in plumbing premises;

- in economic premises, storage rooms;

- in attic and in mansard premises;

- In ordinary residential premises.

Making the calculation of the need for drywall, it is necessary to take into account its standard dimensions and the height of the room, in which the installation of HCL is assumed. Knauf manufactures standard sheets:

- 1.2 width; 0.5 m;

- 2.5 m long;

- Thickness 16, 14, 12, 10 mm.

Gypsum Classification of Gyproc

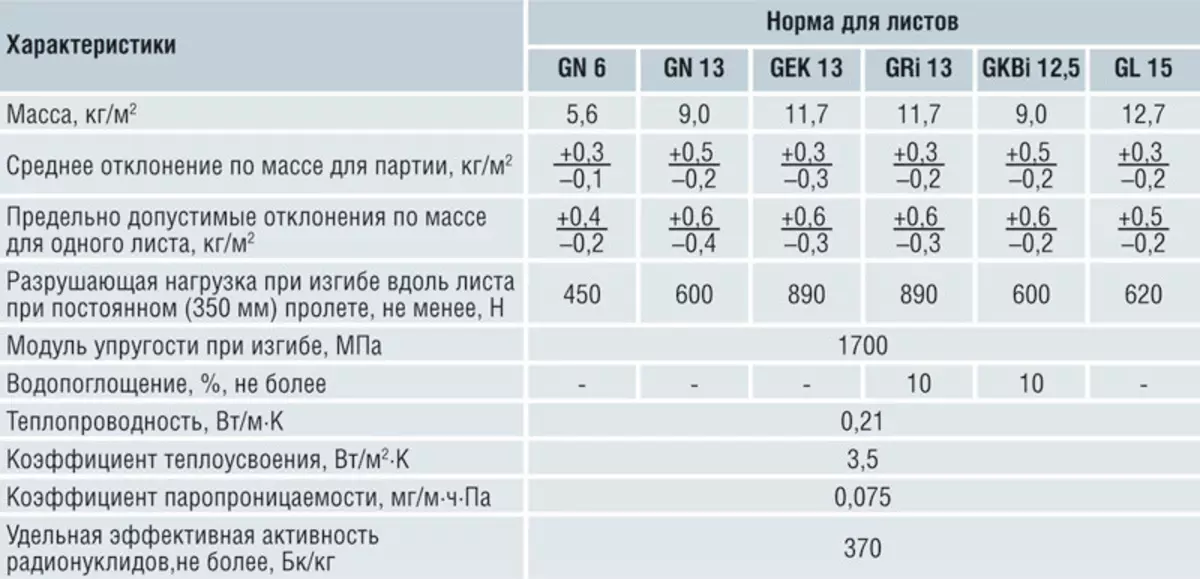

The physico-technical characteristics of the sheets of hypina.

The company produces sheets of 3.6, 3.3, 3, 2.7, 2.6, 2.52, 2.4 m and width 1.2, 0.9, 0.6 m. The company specification in the designation takes into account the special properties of the drywall sheet and its thickness:

- GH13: Normal;

- GNI: moisture resistant;

- GTS9: Waterproof and windproof;

- GEK13: with increased strength;

- GF15: fire-resistant;

- GN6: Recovery (restoration) or repair.

Calculation of the total mass of 1m2 plasterboard partitions

It is usually produced not only to find out the estimated consumption of the material, but also to find out the level of the load that the design will create. The following approximate calculation is fair for standard sheets of GLCs having a thickness of 12.5 mm and used to cover a partition having a metal frame.

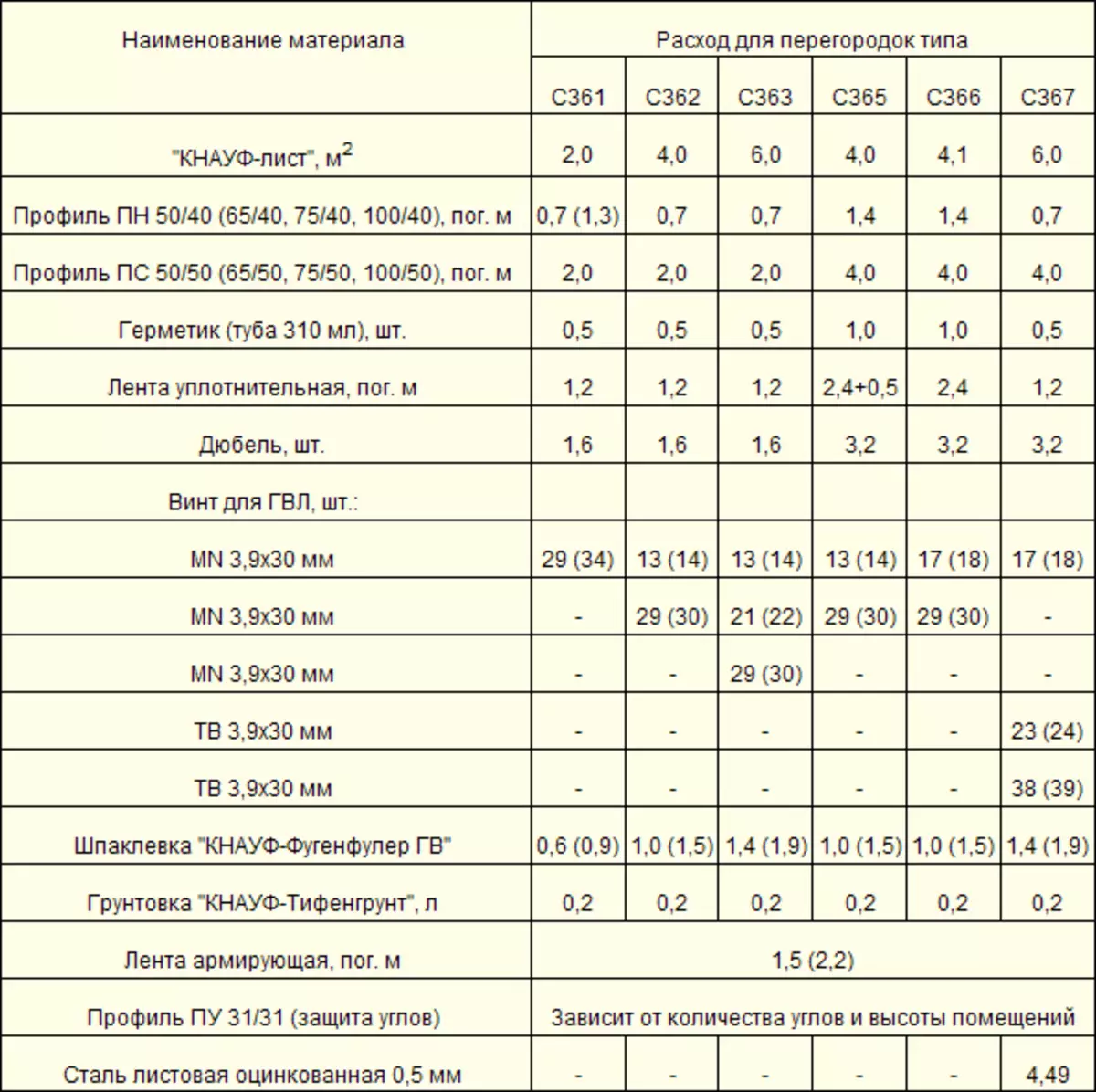

An example of calculating materials for partitions.

- The weight of the 1st "square" partitions with a height of up to 5 m, the framework of which is covered with only one layer of GLC on both sides, is about 25 kg. With the arrangement of the larger height partitions, a thicker profile is used, so the weight of 1 square meters. m will be higher.

- If the partition with a single frame is covered with two layers of drywall, the weight of 1 sq. M at an altitude of up to 6.5 m will be approximately 45 kg.

- When building a double frame and a clamping of GLC in 2 layers, the weight of 1 square. M increases to 48 kg.

- If it is supposed to build a double frame with space for laying communications, then mass of 1 square meters. m will be 49 kg (with a height of up to 6 m).

Article on the topic: What wallpaper options are suitable for a dark room

When building a frame of a tree mass of 1 square. M decreases. But when using wooden bars, the partition height usually does not exceed 4 meters. When building a construction with one layer of drywall, fixed on both sides, a mass of 1 square meters. m will be less than 30 kg. If the frame is covered by two layers of GLC, the weight of the 1st "square" will be 50.5 kg. Knowing the overall mass of partitions, you can calculate the load on the overlap, which is relevant, for example, with the arrangement of the attic. Preparing plasterboard to further finish, any homeowner will be forced to calculate the flow and other materials, in particular, primers, putty. They are the main finishing material when using drywall.

Fighter consumption, putty when finishing the ceiling, walls

- The main purpose of the primer when applied to the surface of the suspended ceiling or the wall is to strengthen the base and increase the adhesion to improve the adhesion of the finishing material with the surface of the plasterboard. Most often, plasterboard is treated with alkyd primer. Her consumption per 1 square. M is 100 ml. For applying primer, the facade soil is best suited for a putty, whose consumption per 1 square meter. M is 130-150 ml.

- In putty, its flow rates depending on the thickness of the layer of the superimposed layer. The calculation shows that on average, 1 sq. M is less than 1 kg of material. For example, "Wetonite" will be suitable for the processing of the suspended ceiling in a dry room - consumption will be 1.15 kg per "Square". For sealing cracks, other small defects are used material based on plaster. The consumption of such a putty - 0.85 kg per "square". At the finish stage for finishing the ceiling it is possible to use adhesive putty. Then consumption will be 0.5 kg per square.

Article on the topic: How the ball crane is arranged

General calculation of materials on 1m2 for walls and suspended ceiling

This is an approximate consumption when using a 12.5 mm thickness on a metal frame (if the partition is, then a height up to 4 m):

- PN guide profile: 0.7 m;

- PS rack profile: 2.2 m;

- Direct suspensions: at least 2 pcs;

- Tape sealing (under profiles): 3.2 m;

- Reinforcing tape (serpent, for example): 1 m;

- Self-timber 9 mm: 3-4 pieces;

- 25 mm screw: 20 pieces - for suspended ceiling, 12 pieces - for the wall;

- Dowels and relevant screws: 6 pcs.

The correct calculation of the number of materials will allow you to protect your wallet from unnecessary spending. However, more accurate primer consumption, putty can only be determined on the site of the construction of the suspended ceiling, partitions or walls.