Modern building materials allow no greater experience in finishing work to people independently create high quality interiors in their housing. Significantly facilitated the life of amateur masters so-called bulk sex, using which many apartment owners solved the problem of an absolutely smooth horizontal surface in the rooms. Filling the floor with new bulk materials is much less time-consuming than its traditional installation, so it gives her an increasing number of developers.

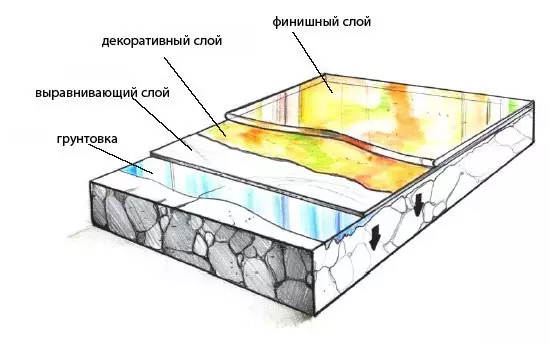

Scheme of a liquid floor device.

The advantages of bulk sex

Choosing a bulk sex for finishing finish is justified by its advantages over other materials. Bulk gender:- durable;

- durable;

- racks to extreme temperature differences;

- moisture constructions;

- has excellent characteristics on resistance to chemical impact;

- fireproof;

- Environmental.

Due to the combination of listed properties, the floor covering this type for many years looks completely new. It does not require careful care. It is not formed by fungus. In addition, the bulk option can be used as a finishing coating for a warm floor, which makes it the main competitor to the tile coating, working with which requires much more experience.

Types of bulk floors

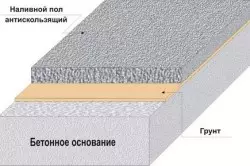

Scheme of liquid anti-slip floor.

There are 2 types of such material - polymeric and mineral.

The 1st are divided into epoxy and epoxy urethane. Both are produced from epoxy resins, but epoxy urethane coatings are used to finish surfaces susceptible to high mechanical loads, and epoxy is operated in rooms with high humidity.

2nd type of bulk floors - mineral. The main components of this material are fillers from minerals, modifiers and cement. High-quality mineral-based mixtures provide high ductility building materials during its fill, the speed of solidification of the layer and long service life. Mineral mixtures have the properties of self-leveling and well spread over the surface being processed. True, these characteristics do not exempt the builder from the obligation of the uniform distribution of the prepared composition on the basis. Mineral materials are often used to align the surface before its finishing finish with other coatings. Mineral-based liquid floors are most often used with the floor of the floor with their own hands in housing.

Article on the topic: How to put iron on the roof with your own hands

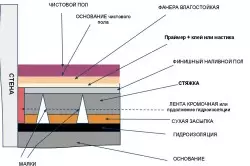

Floor fill steps.

They are used to fill bases with a variety of surface condition. So that work with a bulk coating was carried out more efficiently, mineral mixtures were divided into 3 groups.

- Finish. The compositions relating to it are designed for final finishing. To use the finishing material, it is necessary that the differences in height on the prepared surface are not exceeded 10 mm.

- Average. The mixtures are used to align cement-based screeds, in which the height range does not exceed 30 mm.

- Basic. The compositions of this group align the surfaces with curvature to 80 mm.

Considering the state of the foundation in the residential premises and the conditions for the further operation of the floor, you can choose the material in the store most suitable material.

Preparatory work

Perhaps the main stage in any work is preparatory. It is from how high-quality it will be completed, the final result depends. To prepare the overlap to the fill of the floor it is necessary:

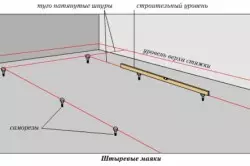

Floor screed device.

- free it from the old screed;

- collect all the garbage, residual solutions and dust;

- save it from any kind of bold spots;

- make a wet home cleaning;

- seal cracks with a solution;

- Align their depressions.

The probability is that you have to do a new screed, because than an even more reason, the easier it is to get it in the future. It is better if the plastic film will be laid under it. For laying a new screed, you need to install beacon profiles. This is done like this:

- You need to find the highest point of the floor.

- On all the walls with the help of the level and painting cord, the horizon is marked with the height of the beacons.

- Between the opposite walls, you can pull the threads that are fastened to the walls by self-draws, which are screwed along the horizontal mark. The threads will determine the plane of the screed.

- Instant beacons are installed. Their mounting to the floor is performed by plaster.

After the gypsum is frozen, the solution is poured and aligned along the lighthouses by the rule, the length of which should be 10-20 cm greater between the profiles. Now it will have to wait for the decay of the solution to continue the filling process of the bulk gender. Immediately it is worth noting that the screed will be finally ready for further work in 4 weeks. During this time, it must be repeatedly watered with water and ensure uniform frozen under the polyethylene film.

Article on the topic: How will it help to transform your interior bamboo and its drawing?

Laying of bulk sex

After complete drying, the base can be processed to the filling process of the finish coating. But before this, the screed must be treated with a primer, which makes microcracks and will create a layer on the surface with high adhesion characteristics. Along the walls and the doorways are stacked by a damper tape. After the end of work on the pouring it will be possible to remove it, because the resulting gap will ensure the compensation of thermal extensions. Running forward, you need to add that the space exempted after the gasket should be embedded with elastic sealant.

Installing pin lights.

It is necessary to provide in the room optimal for filling the floors (15-25 ° C) and the absence of drafts, which prevent uniform frozen mixture. Now you can proceed to cooking. The quality of the floor is influenced by the correctness of its breeding. The mixture should not be excessively liquid. Because of this, the coverage can occur. Insufficiently diluted solution will not be raised. Preparation of the mixture should not be carried out earlier than ½ hours before it is recurring based on the base. During this time, it is advisable to pour and align the floor throughout the room. If you do not have time to do this, achieve the following stamps to match the 1st.

The thickness layer must correspond to ½ cm. If there is a need to make a thicker coating, this can be achieved by filling multiple layers. Work begins on the far from the entrance wall of the room. The solution is recreated with a spatula or ox. The final removal of bubbles from the coating is made by a needle roller. It additionally aligns the surface.

After 2-3 hours, the coating will dry, but complete hardening will occur only after 3 days. You can already pour the thinnest finishing layer, which is covered with varnish after drying.