If the floor is always cold in an apartment or your home, then the only way to get rid of this problem will be his insulation. For this there are a lot of insulation materials, but they all require a clean floor device after themselves. Hearth insulation plywood completely solves this problem, since the plywood itself is a finishing material.

Floor insulation with plywood is a reliable practical and inexpensive way of insulation.

What is insulation and what fane use?

So, depending on which gender is required to inspire, the technology will be special. In general, it is necessary to consider only two options:

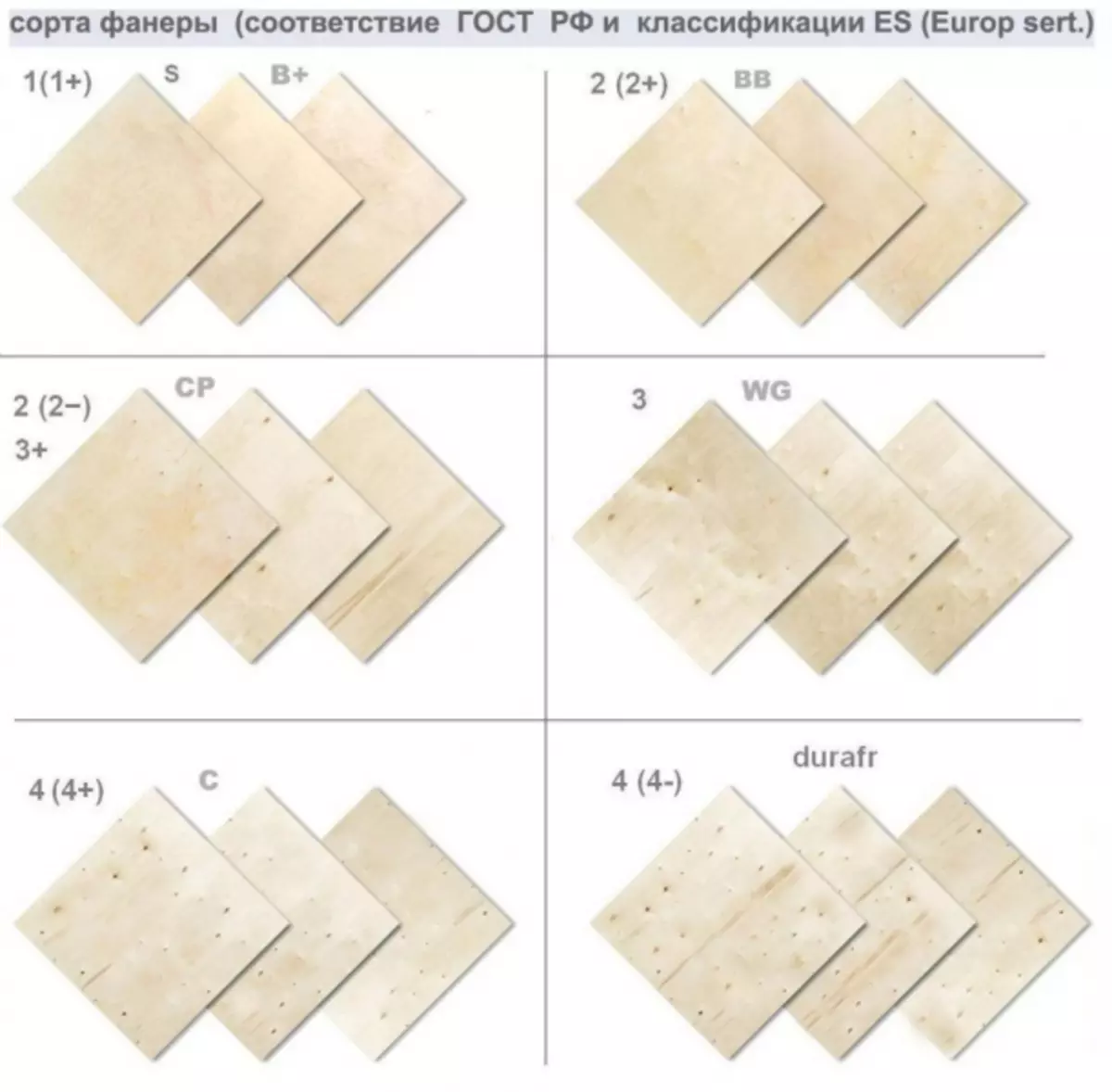

Varieta plywood according to GOST.

- Wood insulation;

- Concrete insulation;

Immediately I must say that there are not all types of plywood for such work.

To date, there are several plywood brands:

- FC;

- FOF;

- FSF.

All of them differ in each other by one parameter - in terms of moisture resistance. But this level is determined by the following indicators:

- type of glue used;

- The type of coating that is applied to the top layer of each sheet.

The highest moisture resistance is the FSF plywood. However, it is used mainly in very humid premises, such as in the bathrooms, in unheated warehouses and so on. It is not recommended to use it at home, since its individual layers are glued with sufficient toxic adhesives.

Plywood may be brands of FC, FOF, FSF, OSP and DVP.

Mark FC is a golden middle. With its manufacture, glue is used that is not toxic. At the heart of the composition of this glue is carbamide resins, completely harmless to human health.

It must be said that there is another sign that affects the possibility of using plywood in a particular place, this is the material of manufacture. According to this attribute, the Fanur is distinguished:

- from coniferous breeds;

- From hardwood.

The first form can only be used in roofing works, as the coniferous rocks are distinguished by various resins. But for the interior decoration, a material made of hardwood is used.

So, of the foregoing, it can be concluded that the optimal for insulation of a wooden or concrete floor plywood will be the one that is made of birch and has a marking of FC.

Article on the topic: Room decoration in summer

The quality of plywood as a factor affecting her choice

As for quality, four groups distinguish:

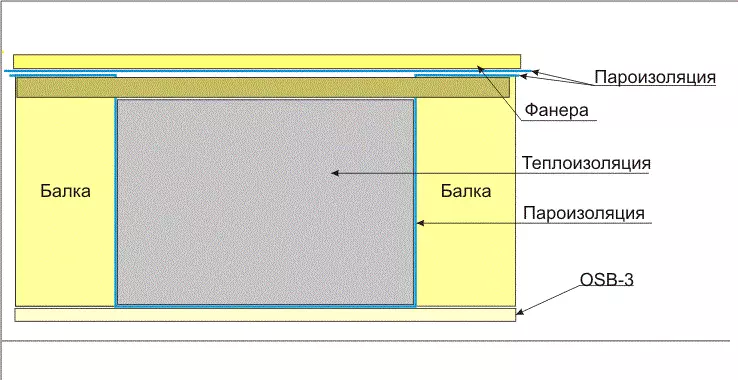

Floor insulation scheme plywood.

- Almost no external flaws.

- There are swirls and inserts from the veneer.

- There are cracks, swirls and other defects.

- There are multi-colored stripes, knots, cracks, inserts from a veneer and so on. Such plywood is the lowest, but the quality of the gluing of individual layers is very high, which allows it to be used as a black floor covering.

It becomes clear that the choice should be based on the purpose of use. If the plywood is needed only for insulation, you can choose the cheapest, if it is used and as a heater, and as an finishing coating, you need to choose the best on the external sign.

Work with concrete floors

Most often, concrete floors are exposed to insulation. This is due to the fact that they are very cold, as very slowly heated and cooled quite quickly.

The easiest way of insulation is to pretend to top Phaneur. As noted earlier, it can also act as a rough, for example, as a basis for laminate, and as a first floor. In the second case, the entire surface of the plywood is covered with varnish or paint.

Sequence of actions for insulation plywood:

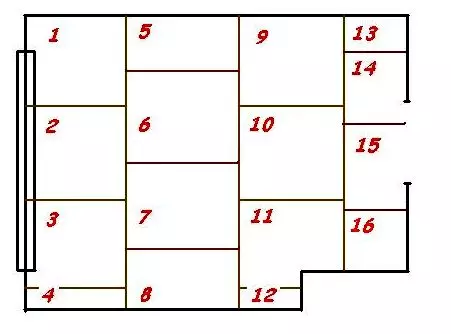

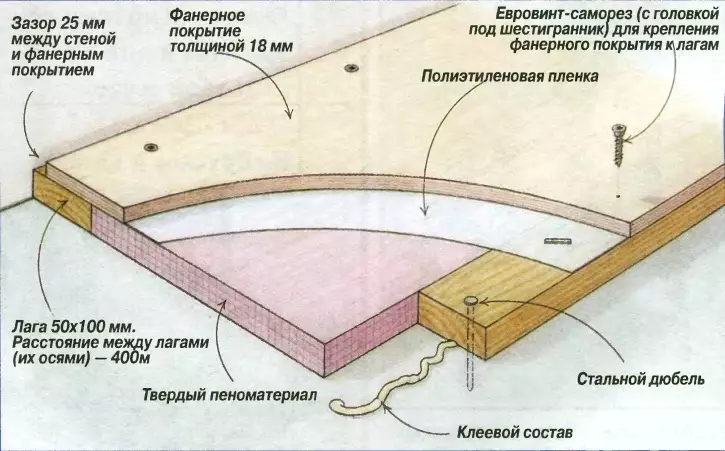

For the strength of the plywood stacked in a checker order.

- Laying on the entire concrete surface of an additional insulation - polyethylene agent. In this case, the thickness of such a heater can reach 8 mm. This material does not allow dampness from concrete to get on the surface of plywood. It has a double insulation effect, since its one side is covered with foil. She puts it up, that is, to the plywood, thereby returning penetrating heat back to the room. Before laying even such a material as Polynevenient, the entire surface of the concrete must be cleaned of dirt, dust and garbage, so as not to damage the insulation.

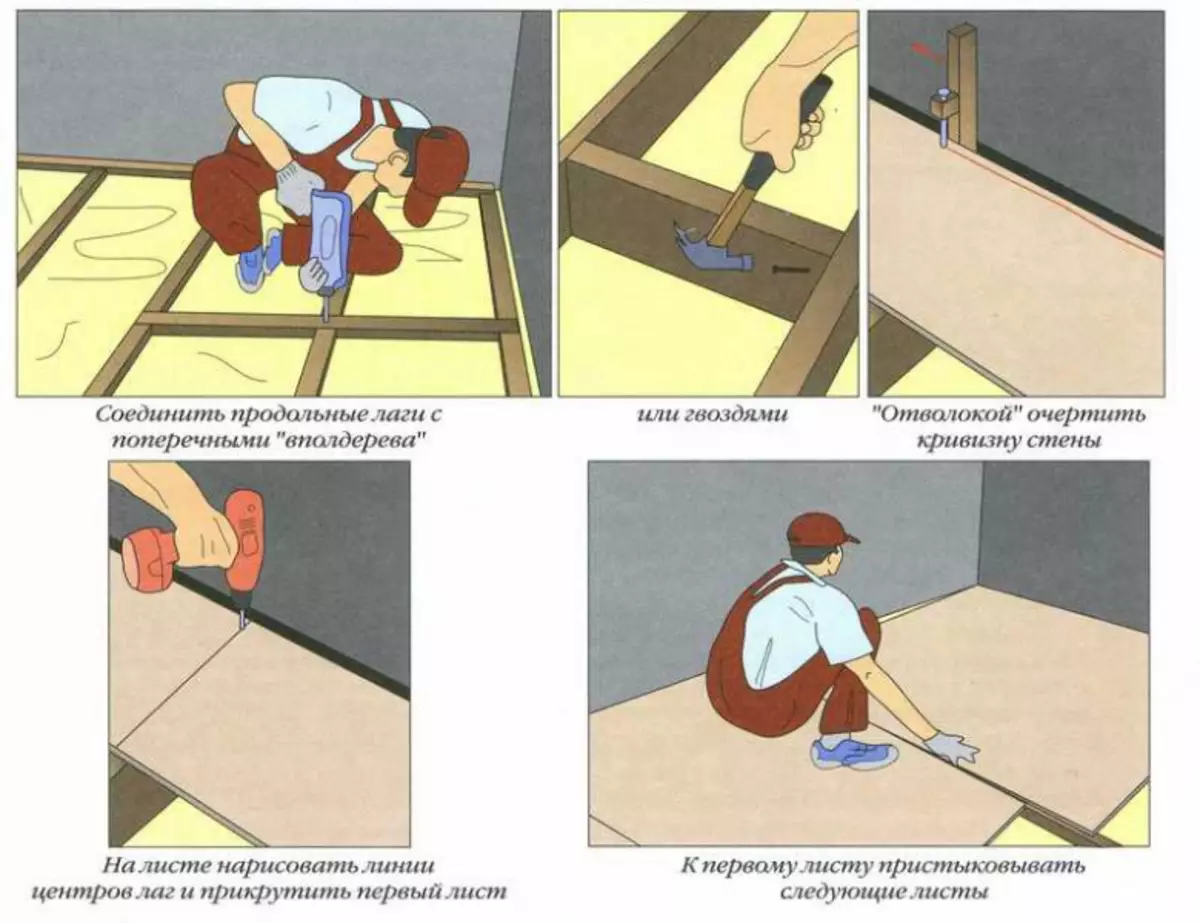

- For the laid insulation, the bars are put on, which will perform the role of the frame of the crate. For this, the materials of the second or even third grades made of deciduous or coniferous rocks are best. Thickness should be at least 4 cm. They are located at a distance from each other at 30-40 cm. At the same time, an indentation of the walls in 1 cm should be maintained.

- Any insulating material between bars is laid on. Mineral wool can be used, and foam.

- On the top on the bars nourishes the draft floor, that is, the boards with a thickness of no more than 30 mm.

- Plywood feels on the board.

Tip! If the floor is not very cold, that is, insteading initially, it is possible to put anything at all between the bars, since the air itself is a good insulator.

Floor insulation with plywood.

Article on the topic: Stand for a TV from drywall

There is a number of subtleties in such a work, for example, the laying of BRUSEV should be carried out with such a calculation so that the edges of the sheets are located exactly in the center. It is necessary so that no edge is over the air.

Since the concrete floor itself is originally uneven, then under the bars it is recommended to put thin rails or sins. Even the slightest irregularity over time can lead to the deflection of the entire design.

As for laying boards, they can not be knit tightly to each other. On the contrary, it is better to leave the gaps between them in 1-2 cm. At the same time, to first lay the boards across the bars, and then, the second layer along them.

For such a floor, it is necessary to use a fairly thick phanener. The optimal thickness is considered 12 mm. Such plywood slightly bends, it will not behave even with high humidity.

Alternative can be considered sheets of 6-8 mm. But when using them, you need to put, as in the case of boards, in two rows. At the same time, the seams should not coincide as in the brickwork.

Work with wooden floors

So, if thermal insulation is carried out using wooden plywood, then the first thing you need to pay attention to the old floor. It is necessary to inspect it for the presence of discussed and fascinating boards, as well as deflection.

In the case when there are rotten boards, they must be replaced with mandatory. If there is a deflection and they are not connected with the state of the lag, then you can install Phaneur.

Plywood flooring stages.

True, there is one condition here - it is impossible to use Phaneur in highly humid rooms. Above the explanations of this.

To check the moisture with your own hands, a simple sheet of polyethylene is needed with about 100 per 100 cm. It is simply put on the floor and tightly pressed around the edges, while the center is left free. In this position, polyethylene is left for 2-3 days. After looking at the inside. If there are moisture drops, then the humidity is high, if it is simply a spirgin, then the moisture is average if the polyethylene remains dry, then the humidity is low.

Article on the topic: Decorative plaster options in the bedroom with photos

If all the conditions are completed, you can start laying. I must say that under the Fanora on the wooden floor, no other insulation is required.

So, plywood sheets are stacked. As in the case of concrete floor, there is a gap of 1-2 cm between the walls and plywood. In addition, the sheets themselves must also be located at a distance from each other.

In this case, it is recommended to the Phaneur with the same thickness as in the previous one, that is, 12 mm.

However, if the base is sufficiently uneven, it is best to use the sheets of a material with a thickness of 15 mm. If the floors are smooth, for the purpose of saving it is allowed to use sheets with a thickness of only 8-10 mm.

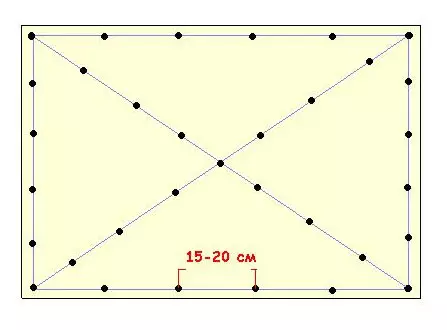

The fastening of plywood self-drawers is produced at a distance of 15-20 cm.

As for the material itself, it is better not to lay it with whole sheets. They are cut into squares with a side of 50-60 cm. Putting them at a distance of 1-2 mm, each other, the optimal supply of damper seams is created. In addition, with small sheets it is much easier to work.

There are some recommendations and on the preparation of the floor. It must be cleaned of dust, garbage and foreign objects. The optimal option will cover the entire surface with the primer composition.

The fastening of plywood can be carried out in two ways:

- with glue;

- on self-tapping screws.

The second option is natural, simpler and fast. Self-tapping screws are screwed into every corner and diagonally. The distance between them should be about 15-20 cm. At the same time, screw them up so that the hats are slightly recessed.

Self-tapping screws should not be closer to the edge than 2 cm. Their length is taken at the calculation of 3 sheet thicknesses.

After complete laying of the sheets, the whole surface is grouped. Then removes and shit. You only need to fasten the fastening sites by self-draws. At the same time, it is necessary to use a special putty on the tree.

After all these procedures, the entire surface is covered with varnish.

In the case when Plywood acts as a draft floor, grind, putty and cover it not necessarily.