The microclimate in the house depends on the compliance with the comfort level of humidity and temperature. The floor in a wooden house is a multi-layered design of boards and thermal insulation material.

In order to protect the building materials from destruction when exposed to humidity, stealing vaporizolation on the floor. In this article, consider the types of moisture preventing materials, and how to correctly perform the installation of the insulating material with your own hands.

What is the insulation from moisture

Parosolation will extend the timeline of wood and insulation

Parosolation of the floor in a wooden house is needed to protect the building and finishing materials from the impact of humidity. In the residential room there is always a humidity, the amount of which depends on many factors.

Wooden buildings perfectly regulate air exchange and humidity level. With increased moisture content, wood is destroyed, a fungus appears and mold appears that negatively affects the health of people living in the house.

The main cause of high humidity in the house is the violation of construction technology and saving on the laying of the waterproofing layer.

The correctly selected insulating material will protect the boards and insulation from moisture, and at the same time will allow the room to breathe.

Types of vapor insulation materials

Materials differ in the magnitude of vapor permeability

There are many different insulating materials. Everyone has their own advantages and disadvantages, so it is important to study all the characteristics and on the basis of the analysis of the analysis of the most appropriate option.

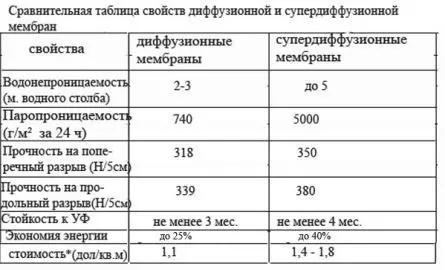

Parosolation materials differ in the structure and coefficient of diffuse resistance (SD, M). The magnitude of vapor permeability is relative and depends on temperature and humidity.

The material that has a diffuse resistance of 0.02 m, forms resistance to water vapor, as a layer of air in 2 cm. The resistance of 0.04 m is the lowest diaphragm threshold with high vapor barrier characteristics.

Note The SD value is a guarantee of the original products of a certain brand.

Polyethylene film

Steam barrier film reinforced with woven threads

Article on the topic: Wiring in a wooden house with your own hands

The most common and economical option that is produced in rolls. To increase the resistance to break the film reinforced with tissue threads. The material is produced with perforation and without such.

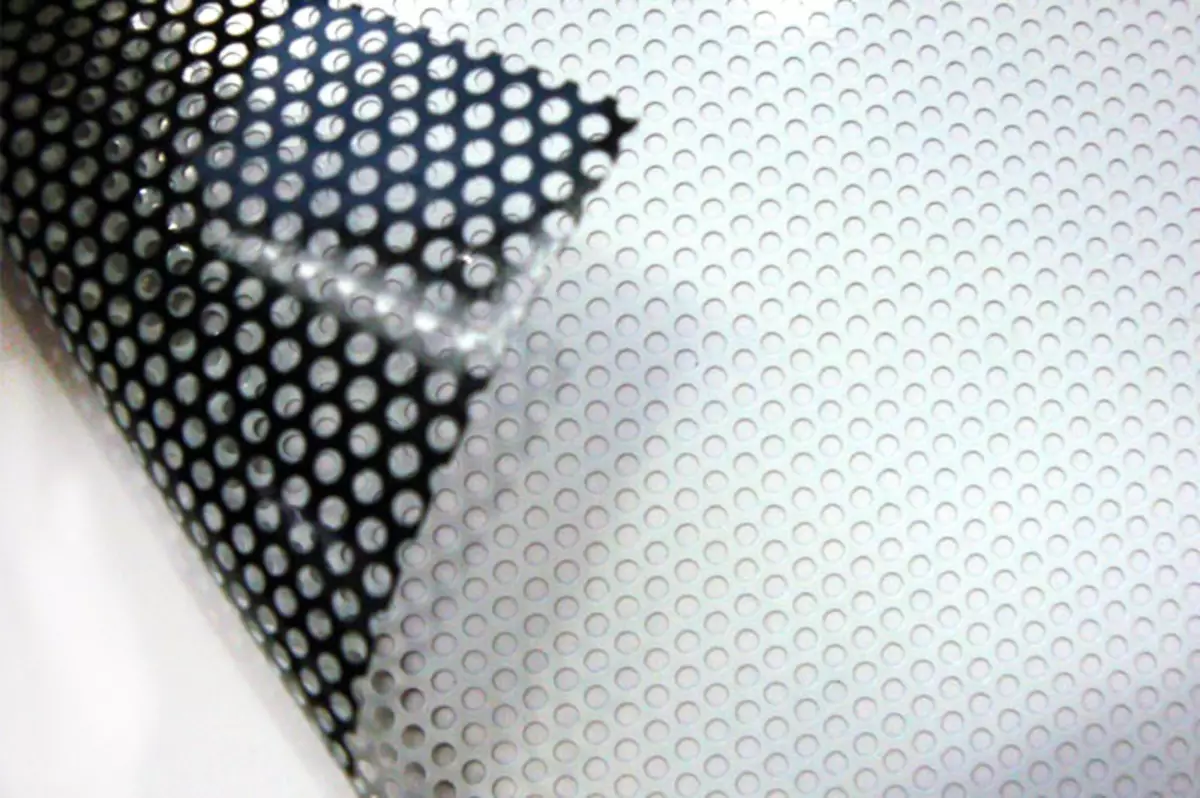

The perforated type has micro-errors in its structure, at the expense of which it has high parameters for vapor barrier, while the diffuse resistance indicator is 1-2 m. It is able to skip a small amount of steam. Most often used as waterproofing.

Non-perforated films have an indicator of resistance of 40-80 m and are a good barrier to the passage of steam, and also protect against condensate formation.

A double-sided film has a smooth surface on one side, and on the other hand, a darning. Roughness hold moisture, do not allow condensate to drain on the insulation. The main minus is that the film does not breathe and is easy to break.

Polyethylene with a reflective layer

The film with aluminum layer is most often used in rooms with high humidity: bathrooms, bathrooms, saunas and kitchens.

It is a good obstacle to the passage of the pair Sd = 200 m.

The aluminum layer reflects infrared rays, due to this maintains heat indoors.

Polypropylene

Polypropylene well withstands temperature differences

Polypropylene films have sufficient strength, withstand temperature differences, while have a higher cost.

The highest quality option is reinforced propylene with cellulose insert or viscose. It has a slight loose matte surface, which is able to keep a sufficient amount of moisture. Thanks to this layer, condensate does not flow to the insulation, and gradually evaporates from the surface of the material.

When laying a vapor barrier with an antioxidant layer, you need to leave a small gap for air exchange.

Foil Material

The combined two-layer material consists of two layers:

- The base (expanded polystyrene, mineral wool, foamed polyethylene) works as insulation;

- Foil aluminum coating reflects the infrared spectrum and has high vapor barrier indicators.

Located with a foil layer in the room. Aluminum coating melts from high temperatures.

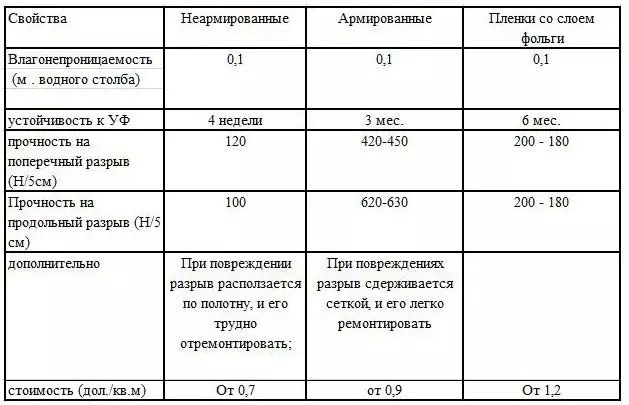

Properties of films depending on the structure:

Article on the topic: Laying of laminate: along or across the room?

Membrane materials

Breathable diffuse membranes are made of artificial fibers.

These are the highest quality, but at the same time expensive materials.

Have a long service life, high steam barlasting and strength.

Produced:

- one-sided types that are dismisted in one direction;

- Double-sided capable of diverting pairs on both sides.

Each of these species may be single-layer or multi-layered. The more layers, the greater the amount of moisture can hold the material.

Before laying a one-sided membrane, it is necessary to be guided by the instruction, it is important not to confuse which side to lay the material.

Intellectual membranes

Intelligent membrane materials are capable of adjusting the humidity and temperature and simultaneously perform the function of waterproofing.

Do not require the device of the ventilation gap and light in the laying.

There are the highest cost models, but justify themselves with a long service life and combining multiple functions.

Floor vaporizoation with their own hands

In a wooden house, the floor is placed from several layers:

- Between the soil and black floor there is an air layer. The subfield is independently ventilated.

- Lagges are arranged from a thick bar.

- Waterproofing, insulation, vapor insulation is stacked.

The optimal option is to lay insulation at the construction phase. In this case, less labor costs. It happens that during operation or repair it is necessary to lay outdoor waterproofing. On how to put vapor barrier when installing the draft floor, see this video:

Preparatory work

During the construction of the house, all wooden materials process with antibacterial compositions against fungal lesions and pests.

Most exposed to the impact of the draft of the blackboard and lags.

We put the vapor layer on the draft boards and put heat insulation on it.

If vaporizolation needs to be laid during operation, we disassemble the floor to draft boards. Check the condition of the flooring. Deformed, damaged by mold or pests of the board change. Lags and the first layer of the floor process protective compositions.

Laying isolation

Stacking vapor insulation material is easy to perform with your own hands. To do this, follow the instructions for installing the selected material and know the sequence of actions.

Article on the topic: Answers of specialists: Is it possible to glue wallpaper on the OSB plate

Stages of laying a vapor insulating layer:

- On the black flooring floor, we settle the selected insulating material so that it lay freely. Strips must be located on 150 mm. Mounted models can be attached to galvanized nails, brackets, adhesive tape. Shakes are sicking bilateral scotch.

- Mount the lags strictly in the horizontal plane.

- We are placing thermal insulation (mineral wool, polystyrene foam, foam). Watch that there is no gaps between lags and insulation. If there is still a space formed, fill it with a mounting foam.

- The insulation is placed on a layer of vapor barrier material, it will be an obstacle to the penetration of the pair from the room. The film is placed so that a small ventilation gap remains. When laying the membrane, the gap is not needed.

- Mount the boards with a gap 2 cm between the vapor insulation layer and the flooring.

- We put the finish coating.

When laying a vapor insulation material, it is important to put it with the right side.

Which side to lay vaporizolation

So that the material used protects the insulation from the penetration of moisture, it must be put according to the instructions for the material. Read more about styling subtleties See this video:

Rules for laying vapor insulation:

- The foil layer is placed to the aluminum coating outward;

- Polypropylene with one-sided lamination decay the smooth side to the thermal insulation layer, a wicker side - to the room;

- Two-way polypropylene can be stacked by any side;

- Bilateral film put on a smooth side to the insulation, Schellus side - to the room; Condensate will accumulate on a rough surface and will not be able to leak to thermal insulation.

These rules are universal when laying a vapor barrier, but we first look at the instructions. For example, the Isyospan-B manufacturer recommends stamping the material with a rough side to thermal insulation, and a smooth surface to the room.

Laying vaporizolation for the floor in a wooden house is necessary, since the bottom layer of the boards is in contact with the soil, from which moisture penetrates to the wood.

The vapor barrier function is to prevent moisture penetration to insulation and boards. The material is properly selected and laid according to the instructions will extend the service life of the floor and promotes the creation of a healthy microclimate indoor.