Floor waterproofing in the bath - the process is very important for the further operation of the room without harm to health.

Putting wooden floors, owners of their own spa try to surround themselves with the most eco-friendly materials.

Increase the service life of a tree in a complex medium of high humidity and modern impregnation will help a constant temperature difference. But before choosing a liquid to protect wood from rotting, water or fire, it is worth carefully learning the composition of the primer.

Necessity processing

When building a bath, it is worth avoiding the use of chemically active materials, they can all lead to undesirable consequences. But at the same time, everyone wants to build for a long time, so wooden surfaces are still worth protecting available for use in active media.

Wooden designs must be treated with protective solutions

It is especially important to limit the influence of high humidity on the tree, since it is precisely under the influence of water that the wood is quickly deformed, its structure is fried and exposed to fungus.

The most vulnerable area is the floor. For flooring in steam or washer used wood that has undergone heat treatment. It helps to avoid strain and drying the bar during operation. But even specially prepared wood requires additional protection.

Ceramic floors are longer than wooden

It is likely that the choice of material for the floor every owner will do it yourself. The pros and cons have all the options. We will look at what is worth paying attention if wood is still used for overlapping.

How to process floors in a bath to increase service life? Are there eco-friendly and harmless means of impregnation of wood?

We read the inscriptions on the package

Before purchasing and handled by any means by the bath, you need to carefully examine its properties. All parameters manufacturers are prescribed on the label, it is important to understand what you must look for.

Article on the topic: Tile in the kitchen on the wall: Advantages and varieties of finishes

| Characteristic | Possible options | The value required for the use for the floor in the bath |

|---|---|---|

| Scope of application | For external or internal works | Used for internal works in hot and wet rooms |

| State of the treated tree | Fresh sawn timber; with unreleased wood; partially affected; strongly amazed | It is recommended to use material without damage |

| Fire protection | It is necessary to process the floor in a close furnace | |

| Antibacterial treatment | water-soluble; Oil; Organic; Combined | Oil impregnation will save a tree from the risk of reproduction of bacteria and give additional protection from water |

| Water-repellent impregnation | Small, medium and deep penetration | It is preferable to choose the primer of deep penetration, but without harmful chemistry. |

It is also worth mentioning that all impregnations are divided into preventive and therapeutic. The choice depends on the state of the wood at the time of processing. The first are applied to fresh wood, more often at the construction stage. The second option is suitable for use in repair work.

It is recommended to use therapeutic impregnations at the construction stage, if it is just known that the operating conditions will be unfavorable, as in the case of a bathroom.

Choose waterproofing for rooms with high humidity

For waterproofing of the wooden floor in the bath, it is necessary to choose an impregnation for internal work in rooms with high humidity, with a minimum content of harmful (toxic) substances, deep penetration, water-soluble or oil.

The main manufacturers of building chemistry have a line of materials for wood processing.

Water soluble protection

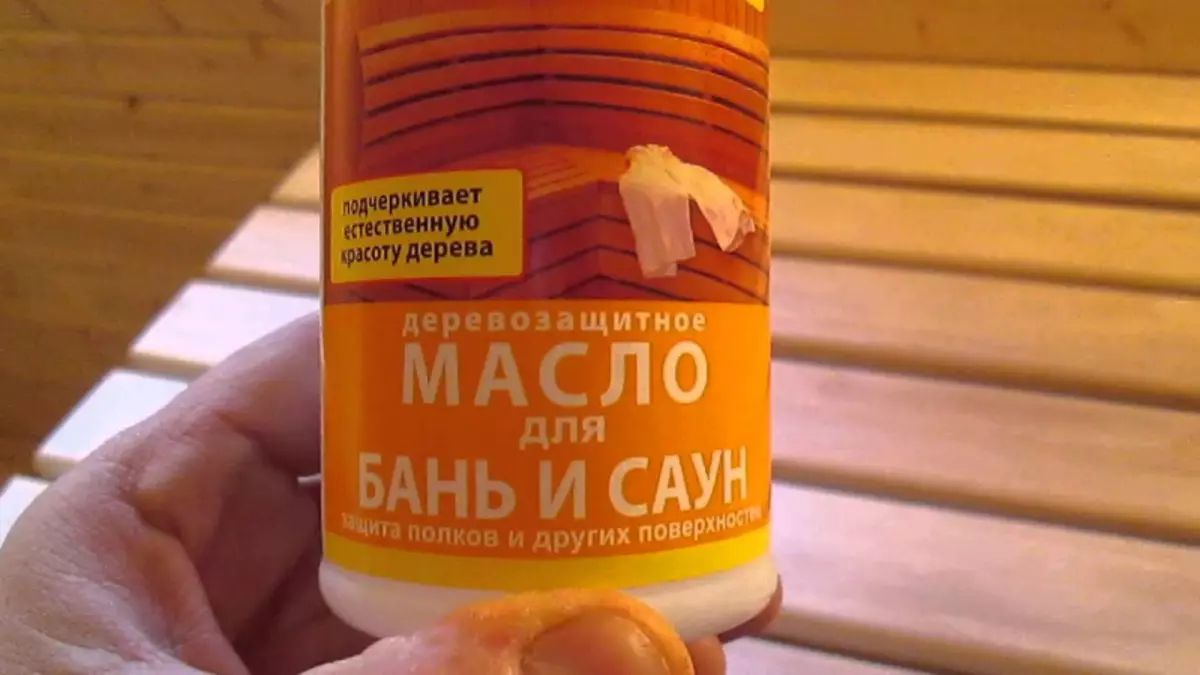

Oil impregnation will also show the structure of the tree, which will give it additional decorative qualities

Water-soluble impregnation on an acrylic basis will create a water-repellent polymer layer on the surface of the tree, resistant to elevated temperature. Such processing will not give the opportunity to absorb dirt and will not miss the air.

Among other things, the impregnation has an antiseptic property, not allowing the reproduction of any bacteria on the surface of the tree. The sex antiseptic of deep penetration will not only protect the wood from the effects of pathogenic microorganisms, but also give an appearance of some nobility, emphasizing the structure of natural material.

Article on the topic: Bath Decor do it yourself

Apply to the surface is worth a thin layer for 2 reasons:

- very long absorbed;

- The thick layer will quickly lose the integrity (cracks), which means its water-repellent properties.

Materials of various brands have additional characteristics, but all one is minus - a fairly high price tag.

Oil material

The composition for impregnation should not be heated and burn legs

Waterproofing of the floor in the bath can be made by an oil-based means.

And it is important to choose the composition that, absorbing in the board, will not heat and burn the skin.

Surely it is unpleasant to enter the pair with heated oils. Formulations with similar properties are developed by Tikkurila, Teknos, Rogned.

The compositions are applied on dry and clean boards, drier about a day, after which the room should be carefully protruded.

If, after a long warm-up on the floor, oil spots were detected, they must be wiped with a clean cloth dry.

Folk advice

If the question is how to process the floor in the bath is relevant, and the funds are very limited, use the Dedovsky method. Soak several times with Olife boards. After the first time, wait for a complete drying and soak again. Then, as in the situation with oil for the floor, the bath is worth it to protrud. For details on how to treat wood baths, see this video:

Choosing to seal a bath floor waste production of vegetable oil (Olif), you save material tools and use guaranteed eco-friendly material.

And as already mentioned, it can not be impregnated for the floor boards. To protect them, it is enough to undergo thermal processing. Such wood is less susceptible to hot air and humidity, has some resistance to insects and microorganisms.