Laminate is one of the most sought-after flooring applied today. Externally, it is very similar to a parquet board, and also has a large selection of color palette, anyone can find a suitable option for himself. This material has excellent external signs, successfully imitating natural wood. The process of laying this type of coating is not associated with some difficulties.

The laminated floor is a strong and reliable material that provides a multilayer fiberboard with a high density of glued waterproof woodcipats.

Laminate is a very strong reliable material. It is quite easy to care for him. Therefore, the process of operation is only associated with positive emotions. The floor covering of this type is characterized by special practicality. Unlike parquet board, laminate refers to a low price category. Of course, this type of material has many positive characteristics, but that it does not bring trouble and problems, the main provisions and rules of installation should be clearly followed. The treatment of laminate after laying plays a significant role.

So that work on installation is not associated with difficulties and inconvenience, all the necessary attributes should be prepared:

- respirator for face;

- gloves to protect against contamination;

- spatula with rubber base;

- soft sponge;

- Any ratherone fabric.

Grinding locks and seams

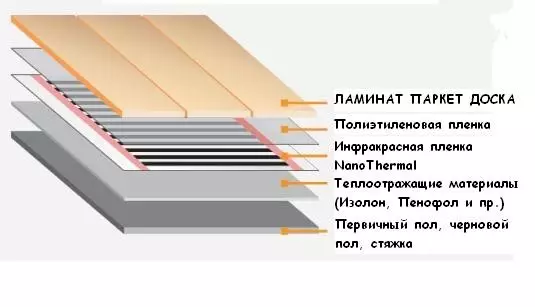

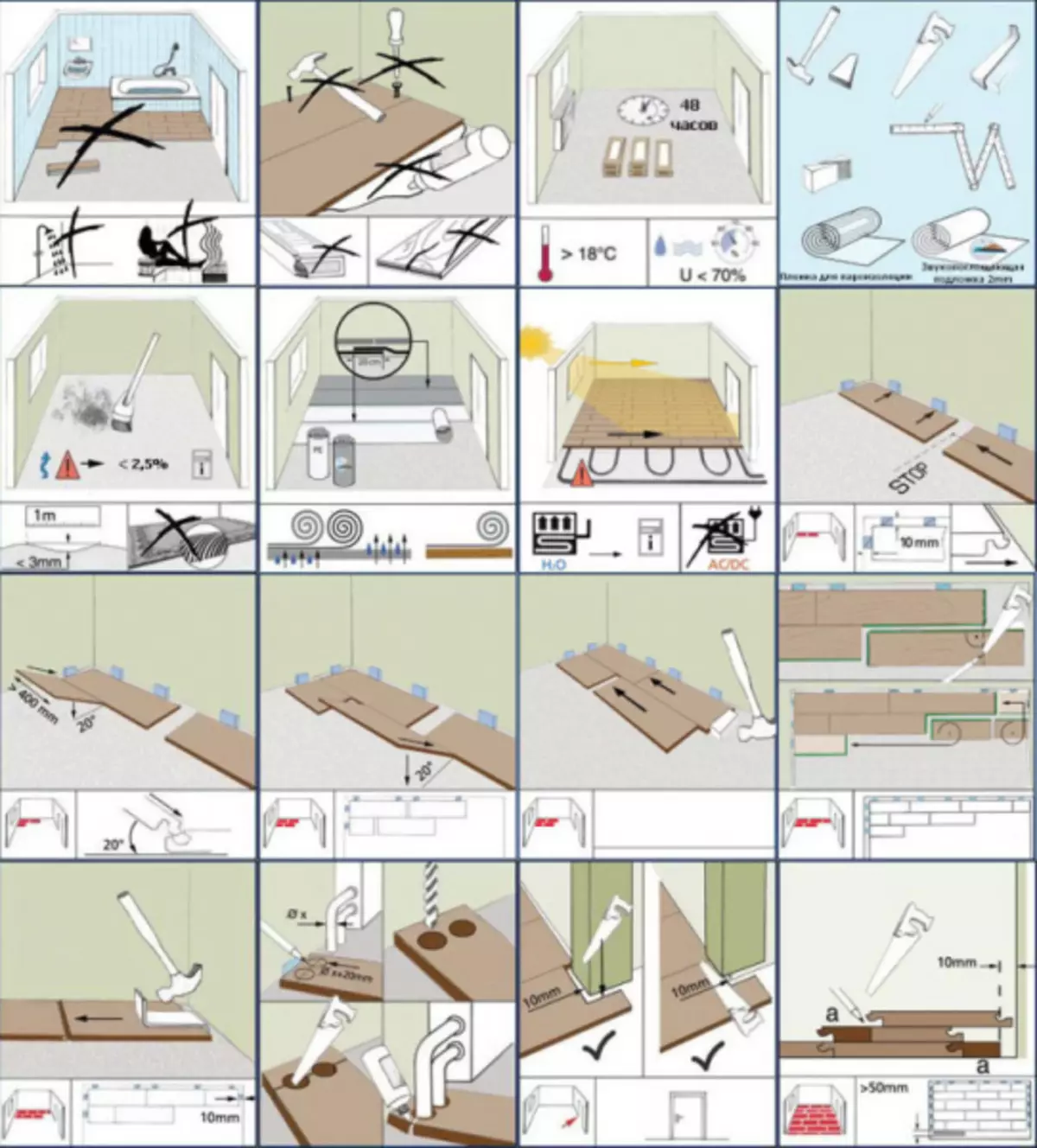

Laminate floor diagram.

The laminate is ranked at the discharge of coatings having a high degree of wear resistance. It is not afraid of increased loads. In order for the laminate to please for a long time with its beauty, in rooms, assumed an increased load on its base, the material corresponding to the elevated class of the fortress should be laid.

And even when complying with such a condition, it is necessary to monitor the condition of castle structures. This should be remembered during installation. Accurate treatment with compounds of such a plan must be a prerequisite.

Sometimes cracks, scratches, chips appear in the panels. In order to return the surface to the original look, you can use putty and wax. The first of these materials is bypassed deep cracks, the second waters the surface to the desired state.

Restoration of outdoor coating wax

Despite the strength of the laminate, the incorrect use can easily derive such a coating from a normal state.

External coating and locks can be protected with special wax.

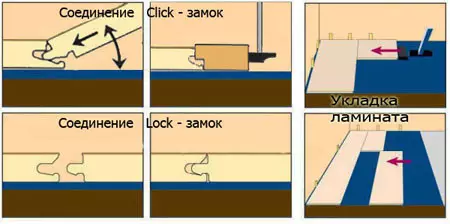

Laminate floor locking circuit.

Article on the topic: What material to make a ceiling in the country with your own hands?

The main factors leading to the sparrel of the outer layer of laminate include various mechanical effects of type of floor walks on heels and, of course, high humidity. The lower the price of such a material, the worse there will be its quality. Even unsuccessfully illuminated item will be left on its surface chip, scratches and dents.

A wax pencil will help to make such damage. As a result of its use, you can not resort to the complete replacement of the panel. Such pencils can be different shades.

In addition, the main advantage of using such a means will protect the surface of the laminate on the possible penetration of moisture in an open place. Wax pencils perform a decorative and protective function. Also, they create a kind of barrier that protects the laminate from shocking, overheating, wetting. Once the lock connections will be processed, follow the laminated board as usual.

Processing joints wax

Laminate laying scheme.

As you know, one of the most sensitive places of laminate are castle structures. They are deprived of a protective base, so they can easily damage due to the regular effect of dampness coming from the outside and from the sexes themselves. Shakes as a result of treatment with wax acquire a protective film, so the moisture is nestric. To use such a pencil should only be in places of castle compounds. As a result of such impacts, you can achieve the following, i.e. Such processing solves other tasks:

- Enhances the castle strength, makes them unchanged due to the impact of heavy items;

- It helps to lay a laminate simply and without much effort;

- Does not make the basis of the floor to creak.

Now you can buy laminate with high locks, but their price will be significantly different. On the one hand, such a purchase will be profitable, because it will not be necessary to spend time on the processing of seams, on the other - such a material should be chosen very carefully, since small defects, production marriage can be hidden under wax impregnation.

Thanks to wax pencils, you can protect the lominal floor from various influences, such as moisture, heating or blows.

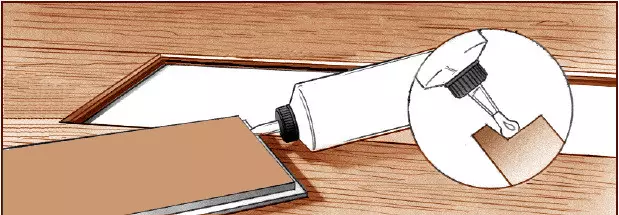

To save substantially, you can buy a sealant, which just consists of wax. Before mounting, handle locks with such a composition. There should be no problems with buying sealant, because most of the producers are engaged in the simultaneous release of laminate care products.

Article on the topic: Wallpaper photo Design 2019: in the hall trendy, modern design, ideas, how to shove in the apartment, sticking, for walls, what in fashion, video

The scratches arising in the installation process can be treated with a wax pencil that is sold in construction stores. Such a means will help to restore the laminate, eliminate chipping surfaces.

In case of severe damage to the surface of the laminate, the wax must be applied with a thick layer in several layers, each of which should dry, and then need to polish them. Such a pencil based on wax before applied to the surface, it is necessary to melt, then lubricate the hole and dry. Before the processing, you need to apply a degreasing composition on the floor and clear well. Properly selected color of the wax pencil will make scratch invisible.

Treat laminate after laying can be special mastic and emulsion that have asom wax, paraffin, polyurethane. These tools create protection, a kind of barrier on the floor surface. Then the laminate will not be afraid of dampness, clusters of dust on its surface and between the seams.

Scheme of sealing slots and grinding of wooden floor.

After laying the laminate, it is necessary to clean its surface well, you can use the vacuum cleaner. All, even the smallest sorts must be removed. You can not allow dust to enter the space between the panels.

Note such a feature that all materials made on a wax should be used only for the processing of locks, since the wax applied to the laminate leaves a divorce and ugly traces.

The mastic is applied with a rubber spatula on the connection points of the laminate panels. Excess means should be removed, then perform polishing the treated surface.

Throughout the work, take care of the safety of the respiratory system: this tool will actively evaporate during such manipulations. You should wear a respirator. As soon as the surface serves (approximately 4 hours), it is recommended to clean the entire surface of the floor.

Special polyrol for laminate

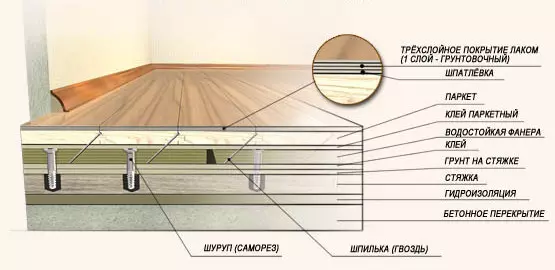

Parquet layout diagram on the screed.

After laying a laminate flooring, you can give a special gloss, freshness and smoothness. This can be done with certain funds.

As soon as the laying is made, the laminated panels are rubbed with a polyrol. Forms of release of these funds may be different. This is a solid mastic, and a liquid substance in the form of a spray. Polyrol do not need to rub very much into the floor surface. Special attention deserves sections with traces of significant damage.

Article on the topic: how to make a cornice for Roman curtains with their own hands

Floor treatment in this variant is very necessary. So that the remedy is smooth, evenly, it is important to use a sponge or soft cloth. A mastic is applied along the line of the lamella, it eliminates the occurrence of ugly divorces and stains. After laying the laminate, the surface treatment of mastic or emulsion is often associated with a significant considerable strength and time. However, the result of applying speaks for itself.

The scheme of applying glue to laminate during restoration.

The base of the laminate can be glossy and matte, so it should be at the processed means. Therefore, it is recommended to choose them based on the properties of the surface of the floor covering. So, the glossy mastic will suit the appropriate type of laminate, the matte here will be superfluous. If the selected material and coating are inconsistent, the floor will look inactively.

As soon as the process of laying a laminate is completed, you should apply any means. It is necessary to do this, as a rule, twice for one year. Such procedures will help maintain laminate in fresh, smooth form. As a result of constant walking over the surface, the effects of sun rays The floor will look impeccable and for a long period to delight beauty, practicality and splendor.

Features of the processing of joints with sealant

After laying laminate, cracks may occur. They are closed with a special sealant solution. It is a peculiar smear for the processing of gaps. Features and application technology are the same as those previously discussed funds.

However, the sealant is more elastic, perfect, moisture-proof material. It has silicone, which is confirmed by its durability and reliability. The sealant is not afraid of high temperatures, ensures the perfect sealing of gaps, seams between laminated panels. Choosing the color form of such a material, it is necessary to take care that its tone coincides with a tint of laminate, then traces of processing will remain invisible.

Laminate is a practical basis for any sex, it remarkably decorates the room, gives it a sophisticated and rich appearance. Successfully selected in the tone room flooring looks luxurious and neat. To maintain it in the initial state, special skills and effort are required. Laminate protection by special means will make it invulnerable, it will be possible to wash it with water without fear, as the joints are securely protected. In order for the floor from laminate for many years, it must be processed.