Pipes for water warm floor have long proved their effectiveness in the heating of the room. They are used as a basic, reserve, alternative or auxiliary means, providing normal conditions for human activity.

Subject to the location of the structure in the region with a mild climate, they may well play the role of the main source, in the middle lane and in the north perform auxiliary function. But when they choose, it is necessary to be extremely attentive and acquire only high-quality and durable materials.

General requirements in materials

The heat-mounted system is mounted only from a whole segment, not allowing connections.

It should be noted that for a warm floor it is better to use special materials intended for these purposes. Only subject to this condition the system will serve for a long time.

It is recommended to refrain from similar analogues, as they are not intended for use in such structures and can burst at any time. Therefore, before buying them, it is recommended to familiarize yourself with the requirements for which pipe is better suitable for a warm floor.

The system must be mounted only from a solid cut pipe, any connections are not allowed. In addition, it is necessary that it is plastic, which will make it possible to fill all the areas of the room without increasing the voltage on its wall.

It should be noted, some photos collected for a warm flooring of polypropylene tubes, cooked in places of bends, are direct violation of technology.

In addition, there is still a number of requirements for the selection of material. Stripping from these characteristics, you can independently choose which pipe is desirable to use your room for a warm floor. Here are the main of them:

- The product must have high mechanical strength. The pipeline in its operation mode is exposed to high physical exertion associated with the system pressure inside it and external from the concrete screed and furniture installed on the floor. Therefore, it must withstand the maximum load of at least 10 bar.

- It is recommended to choose the material only one that is not exposed to thermal deformations under the influence of high temperatures.

- The inner walls of the pipes used for mounting the warm floor should be perfectly smooth without roughness. This will reduce water circulation resistance inside them. In addition, with uneven walls, the fluid movement may be accompanied by a murmur.

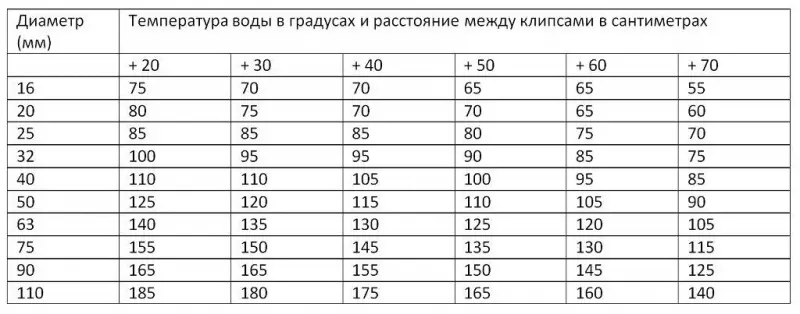

Basically, the pipes for warm floors have a diameter of 16.20 or 25 mm. In this case, it should be noted that the number of mounting elements for the pipeline will depend directly from this value and the average temperature of the fluid inside the system.

Official

In this case, it is possible to repel from the official documentation regulating the characteristics and method of using materials:

- SNiP 2.03.13 - 88, which characterizes the provisions on the use and arrangement of the capital base, flooring and all communications located in the floor.

- GOST SP 41-109-2005, which collected all the revisions of the rules of how polyethylene pipes should be used in heating and plumbing systems.

- GOST SP 41-102-98, similar conditions for metal-polymer products.

- Snip 41-01-2003, which characterizes questions concerning pipes for warm water floor, indicating data from inspections for tightness of systems.

Despite the official arration of rules and standards, you need to do work carefully and carefully. Failure to follow these requirements can lead to depressurization of the system and flooding an apartment or at home.

Independent choice

What pipes are better for the heating device for warm flooring technology: metal or polymeric?

Article on the topic: Pressing the heating and water supply system

Each of the materials has its advantages and disadvantages, so the choice is determined on the basis of the specific characteristics of the room, the region in which the structure is located and the financial sufficiency of the owner.

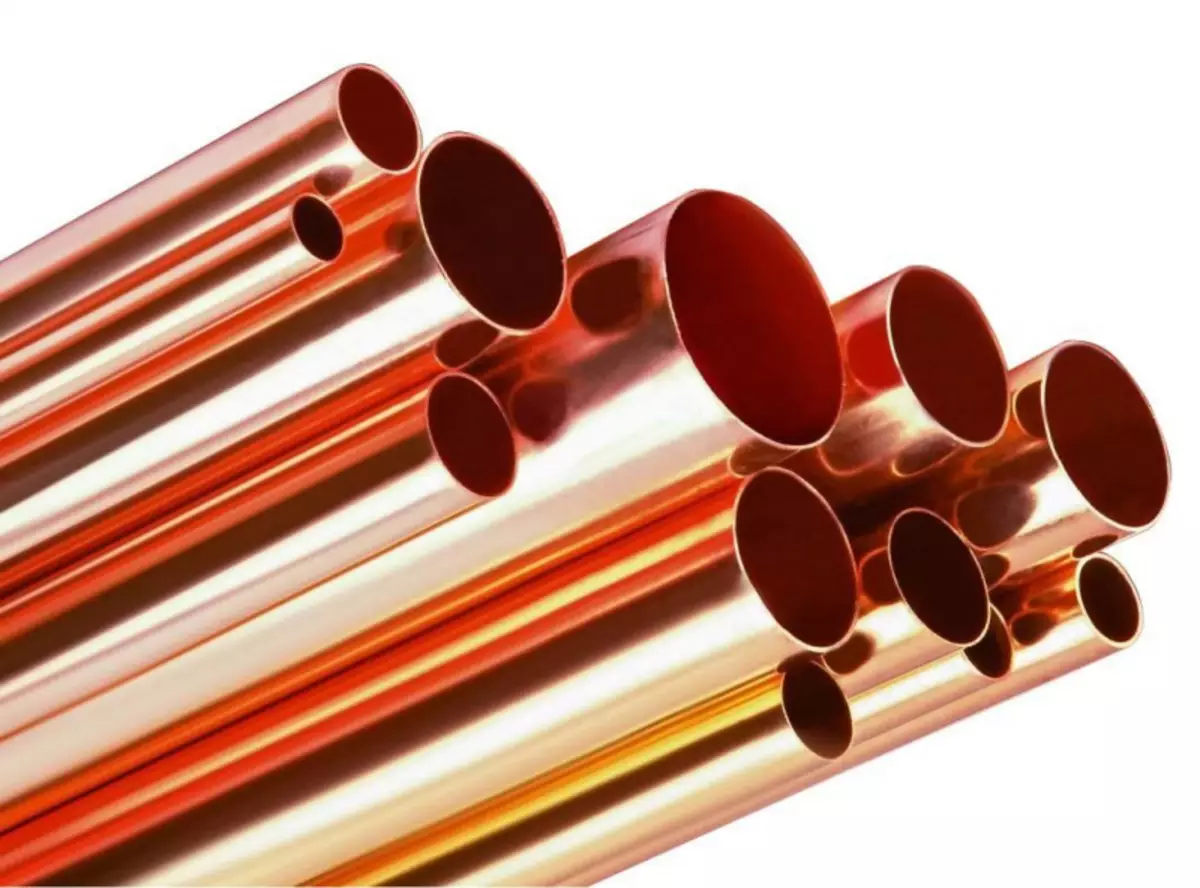

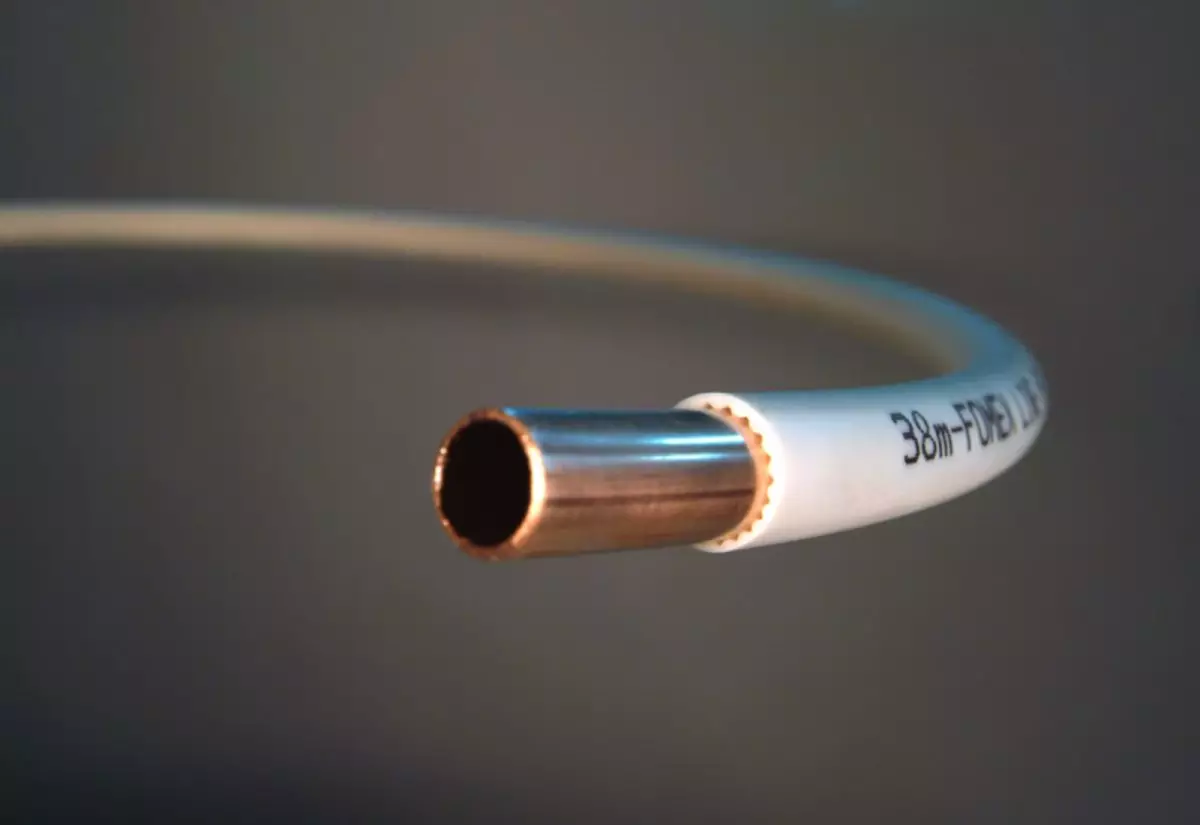

Copper

Copper pipes have a high cost

An overview of the properties of the copper pipeline characterizes it as the optimal option for mounting such systems.

The only thing that does not allow massively to use them is the high cost of the material and the complex installation technology, which again affects the cost.

But the advantages characteristic of copper pipes allow you to confirm the above statement about their advantage among the analogues:

- The metal has high rates of corrosion resistance, it can be concluded from this that the system will last long time.

- Pipes are plastic, so if all the conditions of technological installation were observed, they can be curved in various angles.

- Copper has a good thermal conductivity indicator, which ensures maximum heat transfer.

- The density of the material allows us to talk about its resistance to pressure and drops of temperature fluid temperature in the system.

Stainless steel

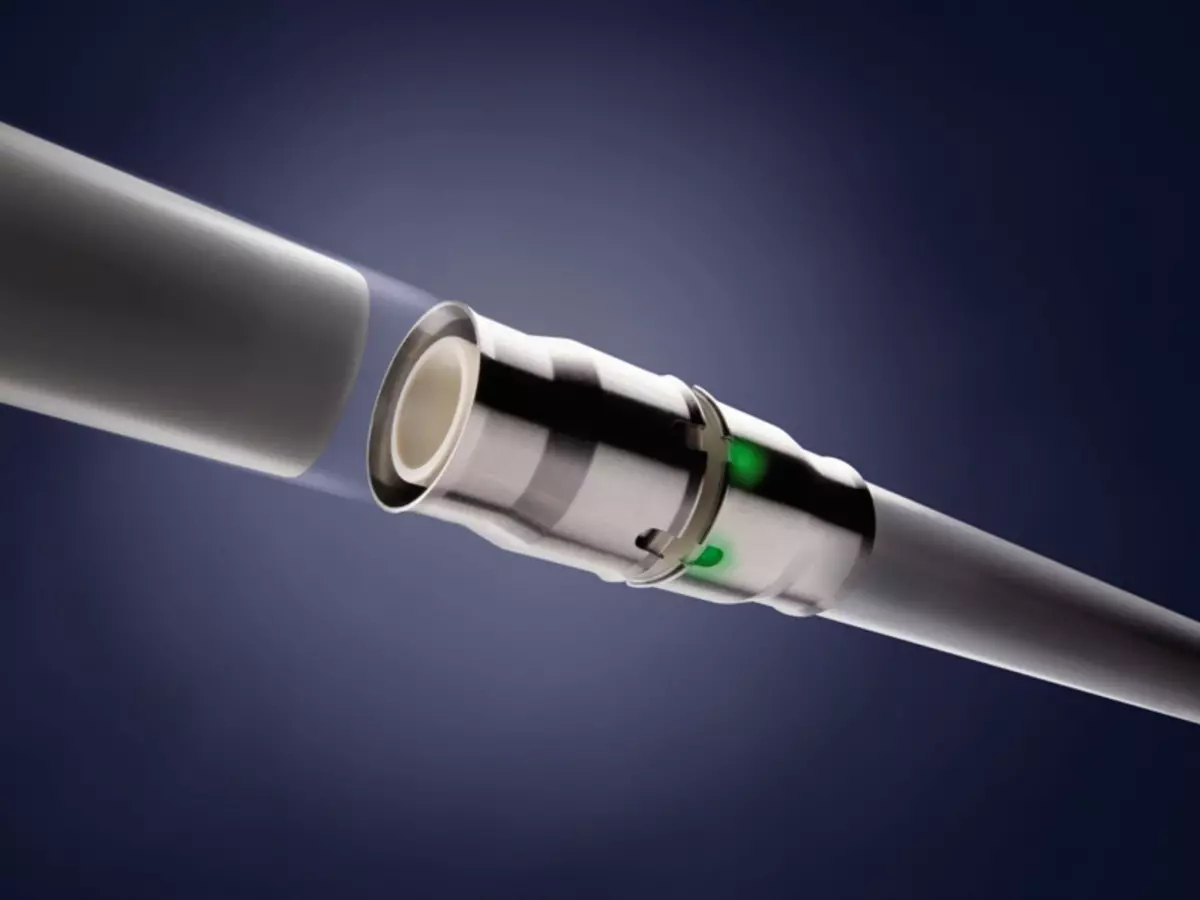

Stainless steel pipes are not corrosion

The disadvantage of special corrugated stainless steel pipes, as in the case of copper, is the high cost of the material. Despite the fact that the water heated floor from such a material appeared relatively recently, he has already established himself from a positive side.

Moreover, the metal eliminates the possibility of forming corrosion, it is covered with an additional polymer coating on top. The advantages of the material are similar to the previous one, the difference lies only in the fact that the stainless steel does not have such good thermal conductivity indicators like copper. But, unlike her, it is much easier than and confidently keeps this bend.

Stainless pipes for warm floor are allowed to use with the use of numerous fittings intended for compounds and wiring of individual segments.

In this situation, this is the only material for which mounting connections in the floor under the tie. His quality gives 100% guarantee from possible leaks.

Article on the topic: Niche in the bathroom: photo assembly Shelves from drywall

Metal Plast

Metalplastic has good efficiency and wear resistance

Metal-plastic pipes for warm floors are the most acceptable option for mounting the system by price indicator. Compared to metal structures, polyethylene is several times cheaper, which allows you to talk about its wide popularity.

In addition, the material has good efficiency of efficiency and durability. Good thermal constant abilities, primarily expressed due to the aluminum layer inside the pipe, which is protected by a polymer layer that protects against mechanical exposure and insulsion. For details on how to choose Pipes for the floor, see this video:

Advantages are as follows:

- long life, not inferior to copper, up to 50 years;

- corrosion resistant;

- environmental friendliness;

- The small weight of the whole design has a considerable value for some types of buildings;

- Excellent sound insulation characteristics, allow us to say that when the fluid moves inside the pipeline, it will not be heard.

Check the quality of the metal plastic can be as follows. When heated to 90 - 100 ° C tube must save its appearance. If layers become visible, of which it consists, it is recommended to refrain from the use of such material and use another manufacturer.

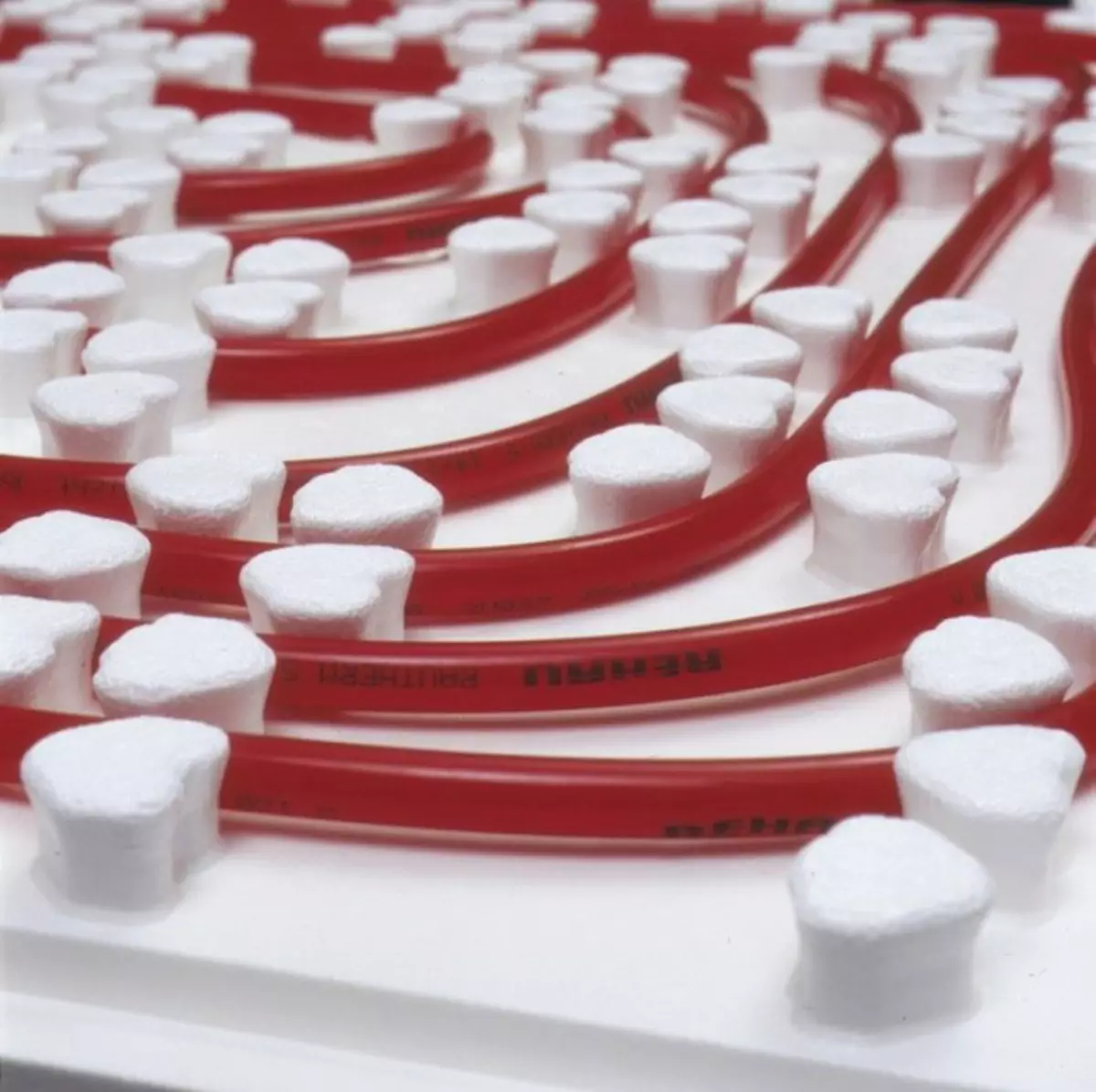

Stitched polyethylene

RSh resistant to high temperatures

The stitched polyethylene tube for a warm floor consists of hydrocarbon molecules unrelated. They are connected under the influence of hydrogen and carbon atoms. This material was called pex.

It has good indicators for use in this technology. It is sufficiently durable, resistant to mechanical exposure and high temperatures.

It should be noted that stitched polyethylene pipes exist several species. The classification is carried out on the basis of the crosslinking processes of molecules, which affects operational indicators and durability.

Materials with a low degree of stitching are susceptible to cracking, and when mechanically exposeds from the side may be damaged.

Article on the topic: Gabions do it yourself in landscape design (35 photos)

Four methods of connection are known:

- peroxide;

- silane;

- radiation;

- nitrogen.

It is better to use for a warm floor pipes stitched in two in the first ways, as they are the most durable in their indicators.

Despite the fact that the material is somewhat more expensive than metal plast, it is significantly cheaper to mount it than metallic systems.

The advantages that will be characteristic of the design in case the installation of pipes for a warm floor of stitched polyethylene will be as follows:

- Perfectly operates in the operating temperature range from 0 to 96⁰.

- Used for laying using warm floor technology it has molecular memory. When heated can be slightly deformed, after cooling takes the former shape.

- It has a good response rate to the chemical components contained in water. Not subject to corrosion and does not contribute to the formation of mold.

- Perfectly holds internal and outdoor pressure up to 10 bar.

- It turns well and restored.

- The selection of a polyethylene tube for a warm floor, stitched according to this technology, allows you to install yourself. The procedure is quite simple.

To a greater extent, being in front of the question of which pipe for a warm floor to use for your home or apartment, the advantage is given to the metalplastic or polyethylene sewn items. This is due to good performance indicators, a small cost and possibility to perform styling on its own or with access to specialists, but with minimal installation costs (work on metal pipelines is much more expensive). On the intricacies of the installation of polyethylene warm floor, see this useful video:

But, despite the amount into which the installation process costs, costs will pay off due to the additional source of heating of the room connected from the main one. In addition, accommodation in such an apartment will become more comfortable, because to step on a warm floor is much more pleasant than cold.