The advantage of such a compound is its tightness even without the use of additional funds, such as sealants, seals, or adhesive compositions. With a folding compound, there is no need to navigate the metal to the crate, that is, there are no through holes on the canvases that can become a corrosion source. The seams themselves play the role of peculiar ribs of stiffness, increasing the strength of the roof and give it a rather attractive appearance.

How is the folding roof mounted?

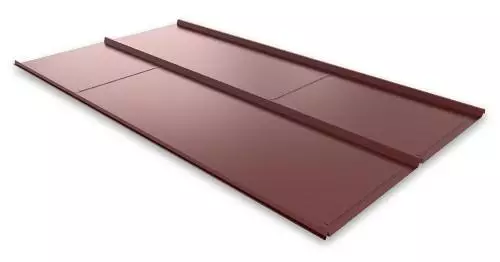

If you look at the folding roof from the side, it seems that solid canvas are attached to the crate along the entire skate, that is, horizontal joints between them are not visible. To achieve such an effect, laying folders are used. The interconnected canvas form a picture. Between themselves, paintings are mounted by side sides with standing folds, which form rigidity ribs. For fastening, special electromechanical sealing machines are used, although you can bore them and manually with the help of wooden bars and hammer. Lying folds are snapped without additional tools. Double standing folding is considered the most durable, reliable and sealed. It is this seam that is most popular when installing folding roofs abroad.

The metal that is used for the roof is quite flexible, which allows it to be used not only on the pitched, but also on conical or arcuate roofs. The height of the fold is usually varies ranging from 30 to 70 mm, which depends on the tilt of the skate, the thickness is 5 mm.

What metal is used for metal roof?

Consider more details on the materials from which the folding roofs are performed. The most common one is Cink Steel - steel sheet, on which a protective layer of zinc is applied on both sides. Among its advantages is relatively low weight, affordable price, ease of installation, the ability to use for roofs of complex forms. The disadvantages include the unreliability of the protective coating, which over time is oxidized under the influence of moisture and destroys.

Article on the topic: Fabric rolets on the windows with their own hands

Polymer coating steel It can serve a longer period. Pural, polyester or plastisol, each of which is responsible for certain blood quality are used as a coating material. For example, Purally reliably protects the metal from precipitation, wind, seasonal temperature drop, polyester makes the roof almost insensitive to ultraviolet, well, the plastisol is responsible for strength. When choosing a coating, you need to determine which material quality is important to you. In addition, polymer coatings give the roof more attractive appearance and have a wide range of colors.

Alucycline - This is a fairly new alternative to galvanized steel sheets. Aluminum alloy (55%), zinc (43.4%) and silicon (1.6%) is applied to the surface of steel instead of zinc. In its protective characteristics, such an alloy is much better than pure zinc, its corrosion resistance increases at least 6 times, which significantly extends the service life of the entire roof. To obtain different colors, aluzink can be covered on top of a layer of polymers.

Coppering It is considered one of the most reliable and beautiful. For such a roof, a ribbon of alloy is used, which contains 99.9% of pure copper. Due to its high plasticity, copper can be used on any surfaces with any form, as well as make various roofing elements from it, such as skates, drains, etc. Waste when installing minimal, and repair is not much difficult, since copper is welded, and it can be soldered with tin. If suddenly, a crack or other mechanical damage appeared on the mounted roof, you need to cut from the sheet to pay on the specified sizes and weld or solder it. The roof, made of copper, greatly simplifies the care of it, unlike other materials requiring certain expenditures on its operation. Over time, the surface of copper begins to be green due to the appearance of a patina, giving the roof a peculiar kind of noble old antique. Some developers, seeking to get such an effect faster, use special compositions that accelerate the appearance of patina.

Article on the topic: Manufacturer Review Profile Dors

Previously, zinc was used for folding roofs, but at present it was decided to refuse it, since it was poorly suitable for the roofs of complex curvilinear forms. Instead of pure zinc, its alloy is used with a number of alloying elements: titanium, copper and aluminum. This alloy is called Titan-zinc , D-zinc or modified zinc. Each of the alloying elements gives the alloy certain qualities: aluminum and copper - plasticity, and titanium is a resistance to corrosion development. Titan-zinc, having a fairly high coefficient of linear expansion, is sensitive to seasonal temperature drops, which you need to remember, leaving the heat gaps between sheets when installing. Alloy, contacting iron or copper elements, forms galvanic pairs with them, which is fraught with the appearance of electrocorrosion at the point of contact. So that this does not happen, it is necessary to isolate iron or copper elements, and when attaching only steel fasteners with a galvanized surface. As the basis for the roof of the titanium zinc, a solid doom is used, and the slope of the skate must be at least 5%.

Aluminum as roofing material has a number of advantages: resistance to natural impacts and sunshine, long service life, low weight and reliability. It is sold in the form of rolls. Perfectly combined with metal siding, which are increasingly used for the exterior decoration of the walls of the house.

Making a conclusion from the above, it can be noted that each of the listed materials is suitable for specific cases. The choice depends on the complexity of the roof design, its shape, operating conditions, as well as the cost of roofing materials. Purchase sheet metal or learn about it in more detail by representatives of manufacturers, on their website or at the points of implementation.

Device metal roof

Now consider the metal roofing device. First you need to choose the materials and the necessary enough items. Please note that the thickness of the steel sheets for soles and drains should be greater than the thickness of the sheets of the main roof, because they experience heavy loads. The thickness of the ordinary sheets is 5 mm, and the sheets for soles and drains are 6 mm.

Article on the topic: Castle replacement on the inlet metal door

Metal roof can be mounted on the roofs, the slope of the skes is at least 10 degrees. Roofing cake under the metal must necessarily have a layer of waterproofing (diffusion membrane) and ventilation gaps so that condensate does not accumulate on the metal surface. As for the crate, it should be solid or fairly frequent (step 250 mm) so that the metal sheets are not saved and not deformed. For crates, wooden bars with a cross section of 50x50 mm are used.

As mentioned at the beginning, the sheets of metal are not nailed to nails to the crate, so the surface does not have through holes. They are attached to the crameset with the help of curmones, while the width of the paintings should be 50-60 cm. The standard sheet size is usually 1x2 m, so before installation it is cut along two parts with scissors or guillotine (can not be used). Sliced sheets can be purchased at once, which will save time and force when installing. Also such roofing sheets will have smooth and neat locks of standard sizes, which is difficult to achieve manually.

The resulting sheets with dimensions of 0.5x2 m are connected to the pictures along the length of the entire skate with the help of lying folds that are bent toward the slope. Clammers are cut separately from the same sheets. In essence, it is metal strips with dimensions of 50x150 mm. Finished coughs are nailed to the crate in 50 cm perpendicular to the shellboards. Pictures climb on the roof, their side lock connects with the end of the beammer and rolled out by double standing fold. You can roll up locks using fasteners and two hammers, or special equipment. Thus, metal sheets are attached to the frame and among themselves.