Plasterboard is a popular finishing material, characterized by versatility and environmental friendliness. In addition, it is completely non-toxic and does not conduct an electric current. Its installation does not require large financial costs, while the results are stunning.

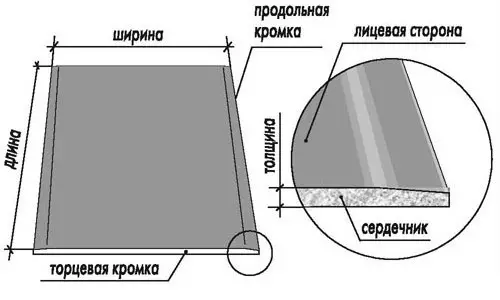

List structure of plasterboard

Anyone who has decided to make repairs using a drywall sheet, wondering how much it will be necessary to prepare self-tapping screws on 1m2 plasterboard panel. As a rule, there is no unambiguous answer to this question, since their number is calculated depending on the step of fastening the plasterboard to metallic or wooden profiles.

Basic rules of calculation

Most often, a sheet of drywall is attached to the profile by self-draws, while the step is equal to 30 cm. If you need to increase the strength of the structure, the step decreases to 10 cm.

Important! Self-tapping screws can not be cast closer than 10 mm from the edge of the sheet to avoid cracking.

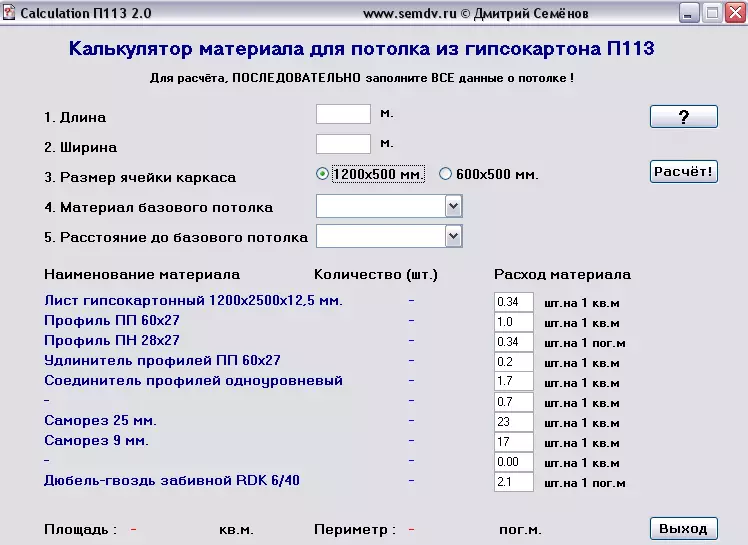

An example of a calculator for calculating plasterboard.

Thus, it turns out that you can only find out the approximate consumption of screws. To determine how much the screws need, you need to consider several parameters:

The size of the plasterboard sheet. GLC is available in standard sizes - 1200x2500 mm. In addition, there are non-standard panels, the size of which is 600x2000 mm. To calculate an approximate number of self-tapping screws, you need to take the first option, as it is more common.

- Fastening step. Experts recommend fixing HCL in 35 cm increments, since this indicator is able to ensure the durability and reliability of the finished design.

- Number of layers of plasterboard. If it was decided to install plasterboard at once in several layers, the screws should be fixed with a different step. For example, the first layer will be attached every 60 cm, and the second - after 35 cm.

Deciding with mandatory indicators, you can correctly calculate the required number of self-tapping screws to attach the sheet of plasterboard. One sheet will go about 70 pieces, and for two layers - at least 110. By selecting a certain step of the attachment and the number of panels for the manufacture of the future design, you can easily calculate the consumption of fasteners.

Article on the topic: Patterns on the wallpaper do it yourself: drawing, applique, accents

Types of self-sustaining

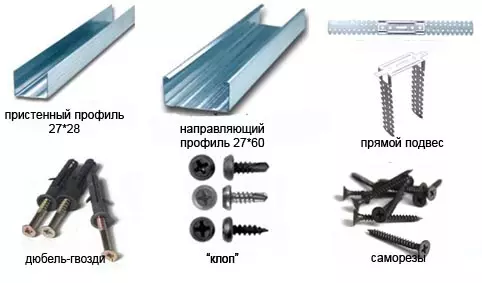

Fasteners for plasterboard have various sizes, types and features of the coating. These include self-tapping screws, on wood, dowel-nails, butterfly dowels and many others. Most often, both wooden and metal profiles are used.

Self-tapes for profiles.

Self-tapping screws

When forming a frame of a metal profile, special self-tapping screws are used for metal. Their sizes are: length 9.5 and 11 mm, diameter 3.5 and 9.5 mm. They are produced with two types of protective coating, namely phosphate and zinc. Their head has a hemispherical or half-cylindrical shape. It is supplied with a Philips Slot No. 2, designed for cross-shaped bits.The base of the heads of the thread is equipped with notches. This allows you to protect fastening from possible self-deduction. The step of the thread in such self-tapping screws is very frequent, this is exactly what distinguishes them from other representatives of fastening elements intended for fastening of plasterboard. Such a fastener is also called the name of the bugs. It belongs to the most sought-after fastening elements, which are presented in the modern construction market.

There are several types of such products:

- Self-tapping-bugs with a drill are used to attach a profile whose thickness reaches 2 mm. With their help, the mount is made without any serious problems. The most important thing is to adjust the scorpovet twist force. This is required to exclude the breakdown of the thread in the profile. To obtain the best result, it is recommended to use a high-quality nozzle-bit, which perfectly combines its own axis with the axis of self-press. In addition, it firmly holds the fastening element when spinning the profile, without deforming the fastener slot. For each type of self-tapping screws used for fastening both for metal and for a wooden profile, the documentation from manufacturers is set out the information described about the recommended twisting efforts.

- Self-tapping screws with an acute end provide the ability to drill holes in metal sheets with a thickness of up to 1.2 mm. When using such elements, the profile material is not destroyed, which helps to preserve its structure. Recommendations for the choice of the appropriate tool and the choice of nozzles are the same as in the first case.

Article on the topic: Vinyl wallpaper from Ukraine: Status, Versailles, Lanita

To better fix the sheet of plasterboard, in some cases an additional magnetic nozzle is used, which goes in combination with a bat. This will ensure a more reliable retention of self-press on the axis of the tool used.

Requirements for plasterboard fasteners

- To attach drywall with self-tapping screws, a large tool kit is required:

- screwdriver;

- Special magnetic nozzles;

- bit;

- Self-tapping screws and wood.

To secure a plasterboard sheet into one layer to a frame, which can be made of two materials, you need to take the screws for metal, the length of which reaches 25 mm, or by wood - 32 mm.

The head of such a fastening element is a hidden horn type. When screwing down, such a self-tapping screw does not break the top layer of plasterboard, as it presses the edges of the cardboard inside the hole. If when working it is not possible to twist the self-tapping screw or it will bend, it must be turned out and replaced with a new one. It is important to remember that in the same hole it is impossible to twice the screws twice. It will be necessary to make an indent of at least 50 mm.

Self-samples: metal, wood.

A number of required requirements are presented to the installation of fasteners for drywall:

- Self-tapping screws should be included in the frame strictly at right angles. At the same time, it should deepen at least one third of its length. In the frame of the metal profile to a depth of at least 10 mm, from wooden - 20 mm.

- The distance from the edge of the drywall to fasteners should be at least 10 mm.

- The screw of the self-press should be recessed into a sheet of 1 mm.

- Between the frame from any profile should not be any extraneous inclusions. If you neglect this rule, the sheet is quite quickly deformed.

TN 25 self-tapping screws are designed to attach a plasterboard to one layer to a frame made with a metal profile. In this case, the thickness of the plasterboard should not exceed 12.5 mm.

Article on the topic: How to make a gazebo of polycarbonate: photos, video, drawings

TN 35 Self-tapping screws are used to clamp the walls of plasterboard. In this case, the number of layers is two.

Important! Suts of the lower and upper layers should not coincide. Otherwise, the design will be strongly weakened.

TN screws are used for profile, the thickness of which does not exceed 0.7 mm.

Self-tapping screws have a step and angle of a thread profile more than that of fasteners designed to work with the metal. Their design contributes to a stronger mounting of the plasterboard leaf to wooden bars. Tree self-tapping screws cannot be replaced by metal screws, as it will weaken the finished design. TN 35 fasteners are trimmed with one layer, TN 45 is two layers.

Sheet of drywall can also be attached using TB screws. Their design is similar to metal screws. The difference lies only in the fact that instead of the acute end, they are equipped with a drill, with which the holes in the profile are drilled up to 2.2 mm. It is ideal for those cases when TN for the profile does not cope with its work. Such a self-sufficiency is perfectly held in the profile made from various materials.

Types of plasterboard

Before resolving the question of how much the screws need it, it is necessary to determine the type of drywall sheet used to build the structure.

Plasterboard is divided into several species depending on properties and destination:

- Normal drywall (GLC) is used only for interior decoration. With the help of such materials, walls, ceilings are facing and mounted partitions in the room in which dry or normal moisture mode prevails.

- Moisture-resistant sheet of drywall (HCCV) has water absorption less than 10%. With the help of such materials, rooms with dry or humidity modes are separated.

- Plasterboard leaf fire-resistant (marked as GKLO). Such plasterboard is designed for facing rooms in which fires may occur. This is possible due to the fact that this plasterboard is characterized by increased resistance to the effects of open fire.

- Plasterboard Glevo combines the properties of moisture-resistant and light-resistant material.