Water warm floor in a wooden house without a screed has a number of important advantages, among which the minimum weight of the design itself and the possibility immediately after installation lay the finishing floor covering, without waiting for that time until the cement screed is dreamed of strength.

In addition, water warm floor without a screed is the most economical heating system, and the filling system is recognized most popular, which does not lead to congestion. The low level of inertia allows for a relatively short time to derive the system to the desired level of heating, spending the minimum amount of energy carrier.

Features of technology

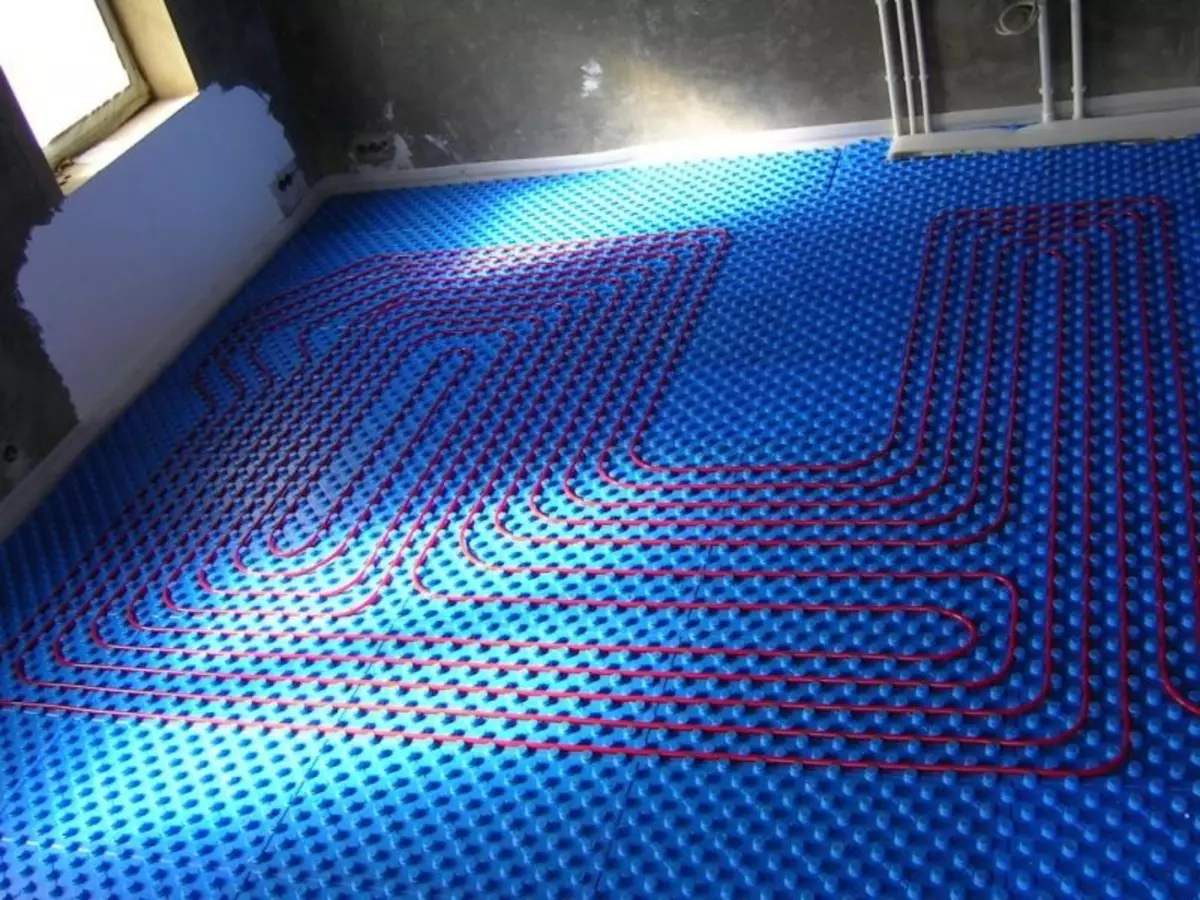

The structure of the dry floor system requires the use of the base to which the contours of the pipes will be laid. Such a base can be made of wood or polystyrene. Another important component is metal stripes intended for uniform heat distribution.

Camping under laminate warm floors without a screed, low heat transfer should be taken into account. To ensure efficient heat transfer, metal plates made on the basis of aluminum are used.

For more efficient heating of the floor, metal plates are used

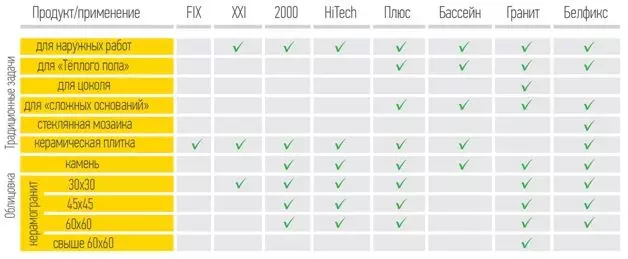

Regardless of the tile or under the laminate, warm floors are equipped, you will have to take care of creating all the conditions for high-quality heat transfer. The most popular today is the Finnish technology, in accordance with which the use of GVL is necessary to create a warm water floor. Such a technology allows you to achieve reliable fastening of all components and not be afraid that the erected basis will "play".

Using a dry screed makes it possible if necessary to carry out the repair of the highway.

The concept and features of the GVL

As the basis under water circuit, hydrococcal

GVL is dry-fiber sheets that are stacked as a basis, serve to fill the voids between pipe contours and are used to create an upper layer under a laminate or any other floor covering.

Article on the topic: Curtains angle and curtains on corner windows - textile decor subtleties

Disassemble such a "pie" in the event of a breakdown and the appearance of leaks, will not be much difficulty, in connection with this, this property can be called the main advantage of this system.

Gvl has many advantages over conventional plasterboard sheets. They are much stronger on deformation and bending, have excellent thermal conductivity. Depending on the diameter of the pipe, the middle layer of the dry screed is created, achieving the desired height and bonding each previous sheet of GVL, followed by tiled glue.

The resulting height should be such that the final layer does not put pressure on the pipes.

The creation of water floor without a screed is possible using aluminum sheets with special recesses for laying pipe contour.

Such plates fit tightly to the pipes and significantly increase the heat transfer, but GVL sheets remain the most demanded due to their technical qualities and acceptable cost.

Their indisputable advantages include:

- affordable price;

- simplicity processing;

- environmental friendliness;

- Fire safety.

Hypox fiber sheets are used to create a base of dry warm floor under laminate or linoleum. GVL belongs to handling materials that are easily cut into segments of the desired length and width when laying the contour of the pipes.

Installation

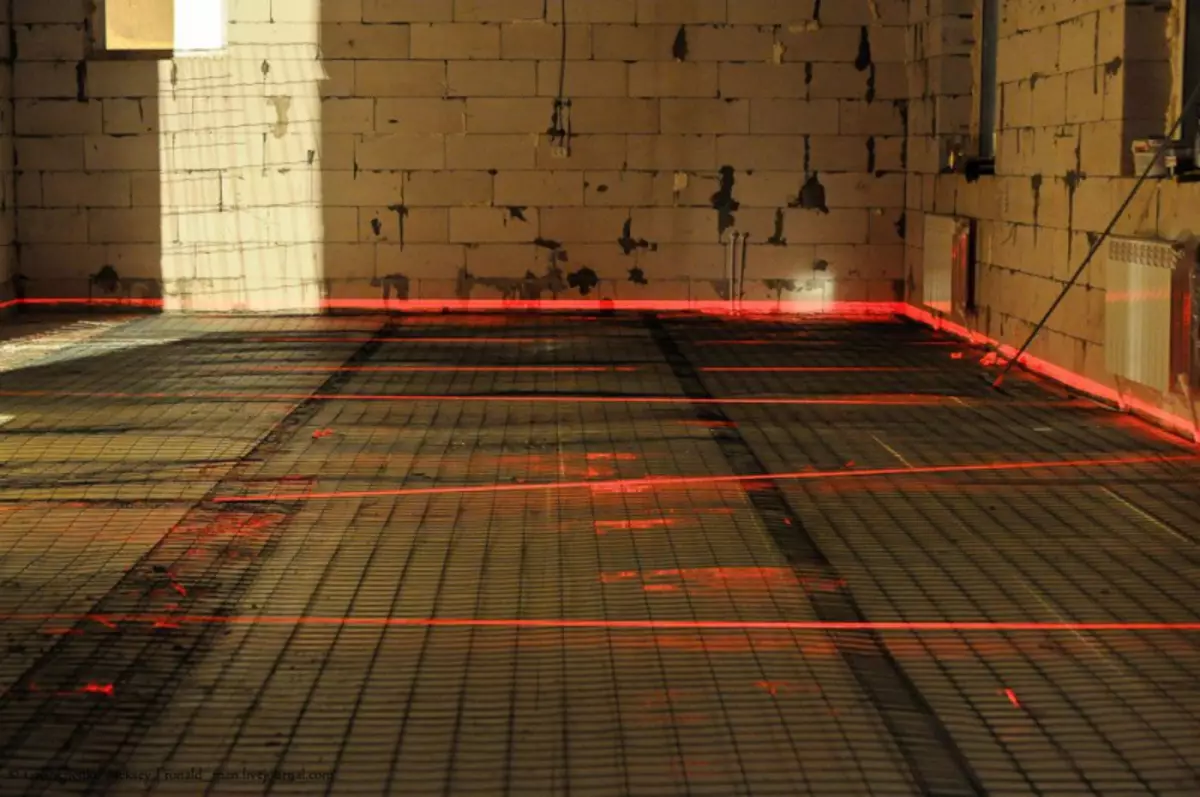

When installing GWL, pair and thermal insulation are also used

There are several ways to fit floors without a screed. One of the most sought-after and popular is the use of gypsum fiber sheets. In any case, the work should be started with the route applying, according to which the loop of the pipeline will be performed.

This scheme is applied to the bottom layer of a dry screed. To create such a basis, it will be necessary between lags to lay such materials as:

- vaporizoation;

- insulation;

- Heat insulation.

Note all the installation places of furniture and household appliances, the corners and the installation points of the thermostat and the temperature sensor, you can start creating a support system.

Heat should rise up, so it is important to pay special attention to thermal insulating materials. It is advisable to use only foil rolled materials during installation, guaranteeing the effective reflection of heat in the right direction.

Between the lags, it is necessary to put the vapor barrier, on top of it the insulation and again a layer of vapor barrier capable of protecting both the wood and the insulation from condensate. To lags, the distance between which does not exceed 60 cm, with the help of self-tapping plates, dry-fiber sheets are fixed.

Article on the topic: Homemade tipper for the repair of the car do it yourself

On the resulting surface, the route of the styling of the pipe loop is drawn, accurately repeating all the turns and bends. Now you can begin to cut the sheets into small strips and screw themselves to attach them to the base of the structure. The distance between the HBL strips should slightly exceed the diameter of the pipes used for the warm floor.

On top of this structure are plaster sheets. They will serve as the basis for the finishing floor covering.

The work of the purchased pipe will depend on:

- area of the room;

- features of the coolant;

- heat loss;

- The capacity of the equipment that will heat the heat carrier.

Features of the installation and selection of pipes

The most in demand remains tubes from cross-linked or heat-resistant polyethylene, which are laid according to the "double snake" or "snail" scheme. This layout allows you to achieve the most uniform heating of the room. What pipes should be chosen for a water circuit, see this video:

The optimal is the diameter of the pipe 16 mm, and the greatest length of such a pipe should not exceed 8 m.

All mounted pipe outlines must be combined and connected to a boiler or central heating.

The system must be equipped with a collector installed for:

- shutdown water supply to separate contours (loops) of pipes;

- adjustment of the consumption of heat carrier depending on the temperature of the floor or indoor floor surface;

- Maintain balanced pressure in all circuits of pipes.

To fulfill all these tasks, the system is equipped with special valves and a thermostat. Maintaining the required level of coolant temperature, ensuring normal circulation of the coolant in pipe circuits in the heat-mall system, the protection of the heated floor from overheating is performed by the pumping unit. For details on the installation of the pipes, see this video:

Dry warm floor is not distinguished by high thermal power and therefore used to create a comfortable heating of residential premises.