Before laying a laminate near the doors, you need to make sure that all the rules and requirements for laying this floor covering are compliance. What is particularly worth focusing:

Laminate laying diagram along the wall.

- Check the height of the flooring with a substrate above the floor base level. Between the upper section of the door frame and laminate should form a clearance of at least 1 cm;

- Laying of laminate should be carried out exclusively on a flat, solid and processed primer basis;

- In the room where the new flooring of the laminate is styled, should not be in the air of excess moisture.

Sequence of work

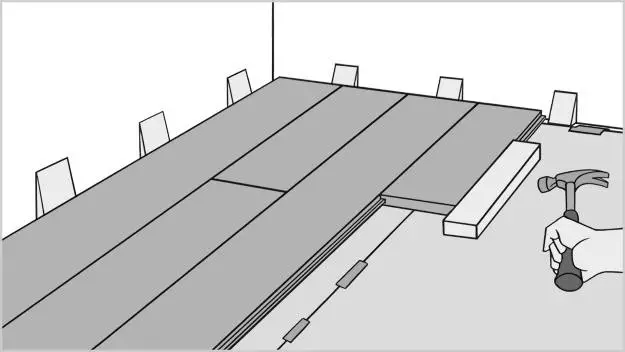

Laminate laying order.

The first action at the beginning of work on the installation or replacement of the floor covering should be an assessment of the state of the basis for which the laminate will be to be laid, as well as how this basis complies with the requirements for the reasons for a multilayer flooring.

High-quality laminate laying is made on the following bases:

- linoleum;

- ceramic tile;

- sex board with a thickness of 30 mm;

- a tie of the cement mortar;

- Plates of fiberboard;

- Concrete slab inter-storey overlap.

The listed bases have a solid surface, which is one of the main conditions for the durability of laminated floor covering.

It is strictly not recommended to lay a laminate for a spinning and soft basis, which can be a carpet, or based on the high content of residual moisture, for example, the xylolite floor, the material for which is a mixture of chemical additives with sawdust of coniferous wood.

Preparation of the foundation for laminate

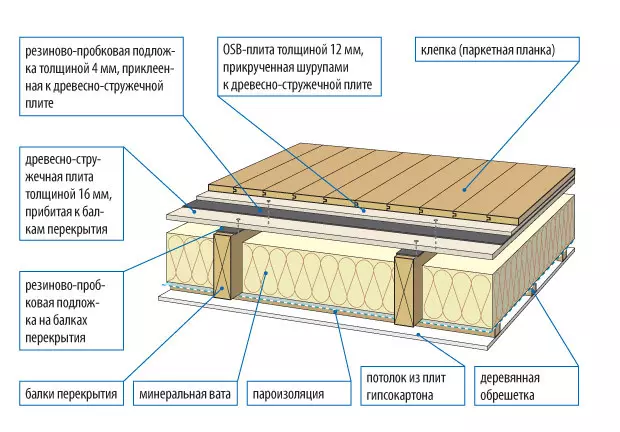

Floor Device Scheme.

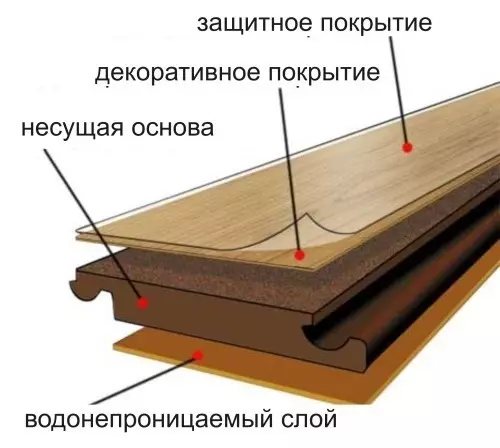

With a high degree of reliability and long-term operation, put laminated (the word "laminate" came to the construction terminology from Latin, where the concept of "lamination") material is possible exclusively on a flat and not contaminated base surface.

Overlooking up to 3 mm thick, which can be compensated by a layer of substrate. All roughness and bulges exceeding this height should be removed by applying a spacion mixture or grinding.

Article on the topic: Simple Curtains do it yourself: manufacturing technology

Old wooden floors scored from convex boards or bars are subject to alignment and grinding. Laminate plates on such surfaces should be laid in the direction as the old coating.

Particular attention should be paid to the state of the base in the zone adjacent to the doorway. This part near the entrance door is more than other sections of the floor will be under constant load.

Application Substrate: Nuances

In which cases are necessary laying of a laminate for a substrate:

- on the basis of mineral materials to protect against moisture and water vapor;

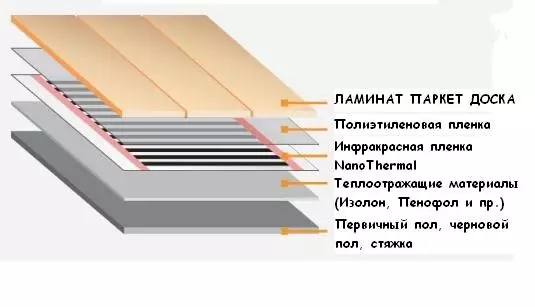

- When the basis is the "warm floor" system;

- with close location of the ground layer;

- In a situation where there is a frequent and sharp change in the temperature of the base material;

- In rooms with basement.

For the manufacture of thermal insulation substrate apply foamed polyethylene.

Laminate structure.

The same material has good sound-absorbing characteristics, reinforce which can a moisture-regulating cardboard rug.

Laying the laminate near the door should take into account another feature of this floor covering. It is made with the use of natural raw material - a tree, which can change its original volume when the temperature changes can change, or, as construction workers, "breathe". Therefore, near the walls and doorways it is necessary to put laminate with gaps from 10 to 15 mm.

In rooms with a large area and several doorways, laminate laying is carried out with the formation of compensating seams at the rate of 1.5 mm seam on 1 p. Coatings. In this case, the "floating floor" system is used when the floor covering does not have fastening with the base, and the plinth is attached exclusively to the walls.

Features of the "floating floor"

In caseless laying, a laminate made by HDF technology is used, which provides high resistance to loads and increased moisture resistance without impregnation.

However, for manual installation, such a coating is not suitable, since the proper docking density is not ensured. Special ties are used for docking, as well as fixing locks mounted directly on the panels. The use of locks allows you to avoid "swelling" or discrepancies of the floor covering.

Article on the topic: How to glue the linoleum online at home: to be allowed to be allowed, adhesive for joints and docking

Outdoor coating at the door

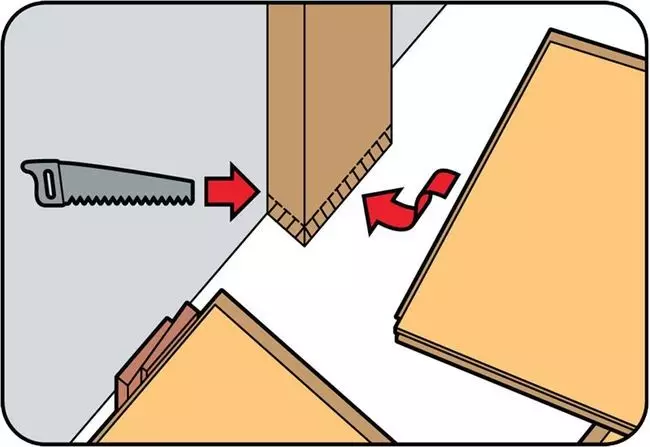

Laying of laminate under the door frame.

According to the builders - finishing, laying of the floor covering, especially such as laminate or parquet, in the doorway and near it is one of the most difficult stages of work with the floor finish.

Laying the laminate around the doorway is performed by 2 methods. According to one method, fitting (trimming) of the laminate element of the laminate is carried out, and in another method, it is drunk in the doorway of the plant under the laminate sheet.

The second method is more professional, since it does not leave unnecessary seams. But he also has his own minuses. The most important minus lies in the fact that when replacing the floor covering to a thinner, making a pipe box under a laminate with a height of 8 mm, the slot will remain, which will require a curly seal. The question and the financial side also arises. If the door frame refers to the VIP-class price category, then you should not hurry with the doorway of the door frame.

The fitting of the laminate under the configuration of the door frame of the above minuses does not have, but when it is executed, the gaps are formed in the places of interfacing of the floor covering and the door frame. They must be embedded, picking up color sealant.

For trimming the door frame, a saw with small teeth. To determine the height of the height, it is necessary to apply the sample of the coating along with the substrate installed. More than 3 mm input should not be given. Tubes before shear is better dismantled.

Then the measurement of the seating and cutting of the boards of the laminate is made. Cropped board should go under a box of 5-10 mm, but at the same time it should not be restricted into the concrete wall of the partition.

The laminate board with the resulting configuration is first fixed along the longitudinal lock (long side), and then with the help of a rubber hammer and a wooden bar, gently drive into transverse locks. With a high board length, constant control of the lack of longitudinal skew, which can damage the locks.

Article on the topic: Curtains of two colors in modern interior design

When driving the doorway, you must first make a template. The template is made of dense cardboard and only after its fit is transferred to the floor covering. The clearance near the door box is required, in order to avoid voltage points. Subsequently, it is supposed to with elastic means for decor.

Laying of laminate: selection and tool features

For fruitful and high-quality work, careful selection and preparation of all necessary tools are needed. Otherwise, a third time spent on performing any operation will be given to the search for the desired device or tool.

If a sequence of operations on laying a laminated coating is known, then according to this sequence and it is necessary to select a tool and auxiliary equipment or devices.

- The first point in any set of builder tools, regardless of the alleged work, is the roulette.

- Then there is a pencil, preferably the construction, but for the absence of it is suitable and simple. But with the hardness not higher than the "TM", and how it will be softer, the more convenient to make them markings. Just in case, you can add a black marker to the pencil.

- For marking panels, you will need a square, preferably wooden to avoid possible scratches by negligence.

- Cutting panels will accelerate the presence of an electric bike or circular saw on a massive bed. Saw even preferable, especially with large volumes of cutting indoors with a complex configuration.

- Wood-hacksaw will be useful for small sleeps.

- Rubber hammer for fitting panels;

- Sliding lump.

- Drill with a set of "Feathers" type nozzles with a diameter of 5-6 mm to create holes on the pipe.

- Metal hacksaw.

- The bracket for tightening the sheets of laminate in the locks.

- Wedges are spacer to control the gap between the walls and edge of the floor covering.

There are no expensive or supervises in the use of tools.