Requirements for a bunk bed

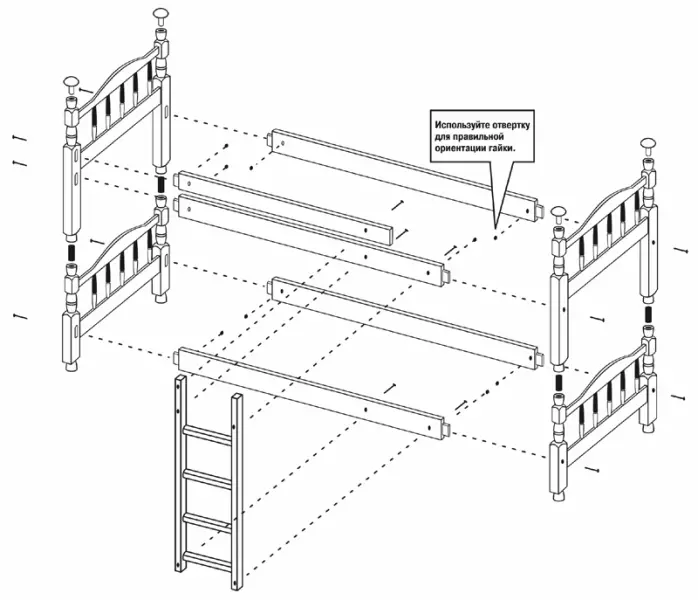

If in the family two children, but not so many square meters, then a double bunk bed will be an excellent option for organizing beds. A similar bed makes it possible to economically use the internal space room. For children, this type of furniture (image 1) will deliver only joy. In most cases, bunk beds are delivered to the house disassembled.

Image 1. Bunk bunk assembly scheme.

To avoid additional expenses, you can try to implement it yourself. This article provides instructions for assembling construction. The bed includes the necessary parts for assembling the bed. If you have basic furniture assembly skills, then the detailed assembly instruction will help save money and assemble a bunk bed yourself.

An inherent condition is that children's furniture must be absolutely safe.

For this reason, the assembly process needs to be suitable with all seriousness. The bed must be strong and carefully assembled. Starting the assembly process is needed from marking places on the main supporting walls of the crib, where wooden bases or cows that are intended for mattresses will be fixed.

Instructions for assembling the bed provides for the presence of such materials and tools:

Bunk bed assembly scheme.

- boards;

- Bar;

- plywood;

- screws;

- Eurovints;

- hacksaw;

- drill;

- chisel;

- a hammer;

- screwdriver;

- electrolovik;

- roulette;

- pencil;

- line;

- level;

- sandpaper.

Back to the category

Build bed

Mattresses are measured, under the size of which plywood substrates are cut. 2 cm should be provided in order to conveniently cover the mattresses of the sheet. After making markup, you can move directly to the implementation of installation work.

First, 2 lateral frames are made. For this, the timber is used with a cross section of 5 * 10 cm, which is fastened with screws. The boards (15 * 2 cm) are screwed to one of the frames. Moreover, the connectors must be both durable and neat. Self-tapping screws should not break through the wooden elements, speaking by pointed ends outward.

Article on the topic: Cross-cross-white embroidery schemes: free contour, download without registration, love pictures with couples

The second frame is similarly equipped with a side. It is made from a board having a section 20 * 2 cm. For a two-tier bed legs, a ram 5 * 10 cm is used. Their length must correspond to the size of the second tier of the structure.

In vertical bars located on the legs, holes are made under the screws. Screwing screws is carried out:

- At the location of both tiers of construction;

- In the side frames.

In the legs, the creation of small recesses is created. They should sit the washers and heads of 6 faces. Screws are screwed into all holes. The deepening with their heads are closed with putty.

Instructions for assembling the bed provides for the correct arrangement of the design in relation to the wall. If the wall is usual, then it is better to use the laser level to align the bed. When plasterboard walls, the drilling of the holes is carried out into vertical profiles.

Under the mattresses it is necessary to install transverse lamellas. This ensures the creation of a reliable and comfortable bottom of the mattress. It is especially important to do it qualitatively on the top tier, so that the mattress does not fall on the child underlying. We carry out this operation by fastening the transverse jagging planks to the longitudinal bars. The mounting step of screws is made up 25-30 cm.

Both design boxes under the mattress need to be laminated by laminated boards. These boards are attached using special screws with countersunk heads. As an additional element, you can use flights. They will prevent the child's fall out of the crib.

The design of the construction assembly of the plywood sheets and stairs is completed. Their high-quality fixation is made with the help of Eurovines.