Table of contents: [Hide]

- Historical backgrounds of the appearance of metal beds

- The advantages of metal beds

- Metal bed design and production technology

- What do you need to make a metal bed with your own hands?

- What are there metal beds?

- Some classification information

Metal beds. Many who have heard this phrase do not come to delight, and with horror they imagine the design of a sample of Soviet production, having an unattractive appearance and a grid as a base.

Today, metal beds are very beautiful, and can be a real decoration of any interior.

To date, everything has changed. And metal bed manufacturers enjoy all the capabilities provided to them in order to create true masterpieces. If you want to buy or make a metal bed with your own hands, then you just need to know some information. For example, then where did metal products come from which they are and what you need in order to make such a model yourself.

Historical backgrounds of the appearance of metal beds

Motherland such structures can be called the ancient Egypt with confidence. In those distant times, the value of the metal was at the height, which is why only wealthy citizens and government representatives can afford to have a bed of metal.

Metal beds The Times of the USSR were not very beautiful, so many today are biased to them.

Conventional people had to sleep on wooden devices. Gradually, the value of metal decreased, and such a bed became affordable for ordinary representatives of humanity. The only difference between the beds of the rich and poor was the appearance. Forged beds that have the kind of real masterpieces belonged only to the nobility, and the simplest models were delivered by versions.

After the aluminum production has become available, the metal beds lost their former appearance and became simpler and unattractive. However, their number has grown at times.

European manufacturers of the twentieth century made metal beds for private households. But Russia, more precisely, the Soviet Union, established the production of a serial nature of metal structures intended for accommodation in medical institutions and barracks.

The collapse of the Soviet Union brought a lot of changes in many areas of life, including concerned and furniture production. At this point, the beds made of metal again acquire their deserved popularity, the method of forging and others.

Forged beds are very beautiful, but they are an order of magnitude more expensive than ordinary metal beds.

The difference in the quality and appearance of modern metal beds, compared with the models of the last century, is significant. Improvements concern and process processing, which significantly improves the qualitative characteristics of the metal, and the appearance. Using advanced technologies in the design of the appearance of a metal bed, manufacturers achieve the production of original and very attractive models that can be installed in the highest interior.

Article on the topic: How to drill tiles

Back to the category

The advantages of metal beds

After you have familiarized yourself with the history of the origin of metal beds, you can move to the voicing of their advantages. Here is a list of some of them:

Metal beds are environmentally friendly.

- When used for the manufacture of parts of the hollows, the weight of the lack turns into an advantage;

- Environmental safety of such a design;

- High degree of wear resistance, since any metal is quite durable material;

- hygiene indicators are at a high level;

- resistance to the effects of loads of high degree, both weight and temporary;

- immunity to mechanical impact damage;

- Infertility of deformation.

And now a lyrical digression concerning wrought bed models. This option is very aesthetic and is decorating the interior of the bedroom. Despite the fact that the metal causes association only with something impressive, heavy and unattractive, wrought beds do not have any relationship to this.

Watching a metal bed decorated with wrought elements, you can only admire her beauty. Light ajuras, smooth lines, stylish elements: All this refers to a metal wrought bed. But all these qualities do not reduce its degree of strength.

What caused such a combination? Everything is very simple.

The stability and reliability of the metal bed is due to its design, which has welded elements, allowing very firmly to fix the components: backs and frame.

Production of wrought beds is possible to order according to the individual client project. Forged pattern can be different: from the simplest option to an exclusive one. After purchasing such a bed, you can proudly show it native and familiar as the only and unique copy.

Back to the category

Metal bed design and production technology

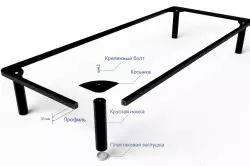

Typical frame for a metal bed.

If we talk about the modern factory production of metal beds, then they are manufactured at the enterprises involved in metal processing, furniture firms, as well as in private shops that have the opportunity to produce forged furniture.

- Material for the manufacture of beds are dirty thin-walled pipes, various rods and wire. They can be made of brass, iron, carbon steel or galvanized metal.

- The methods of making metal structures include two main: welded and wrought. Using the Rooks implies the compound compounds under the influence of the high mode temperature and the use of solder.

- The forging method can be carried out both hot and cold method. Cold manufacture is performed from metal blanks on a special press conveyor under the influence of high pressure. Thus, the desired form of detail is achieved. A hot method implies heating to a certain temperature and subsequent giving the desired form with the help of hammer. This procedure is performed manually either using mechanics.

- The final front of the manufacture includes finishing processing. This is the application of a polymer coating that gives the surface of the product color and performing protection function. Usually, powder paint is used for these purposes. What does this processing give? First, resistance to corrosive processes, secondly, prevents the appearance of fungal infections, thirdly, the metal acquires an attractive appearance.

Article on the topic: A few options for eliminating the edge of the floor from the chipboard

What parts are part of the metal construction? It:

The bunk metal bed will become an excellent option for the nursery.

- framework;

- backs;

- frame and base;

- legs;

- Fasteners.

The frame for the metal bed is most often made in the form of a rectangle, but sometimes, however, it is quite rare, you can meet a round option. Filling the frame (base) is: a grid made by weaving from steel wire, lamellas (again from metal), springs and lats of wood.

The legs of the bed (supports) are placed in the corners of the base. As for the back of the bed, then options may be different. Sometimes it is one back, and sometimes two. The back, located in the headboard, usually exceeds the height of the back in the legs.

Back to the category

What do you need to make a metal bed with your own hands?

Someone, reading the title, can say that this is a rather stupid and useless idea, make a bed with your own hands. After all, today's furniture market in great abundance offers various bed options. Size, design, material manufacturing - All this can be chosen to your taste. And the price categories are very diverse.What is the reason for choosing self-making? Most often this desire to have a bed, unlike everyone else. Well, the second factor, despite the large variety, is still the price of high-quality metal beds.

Make a bed with your own hands is simple enough, either wooden material or metal is most often used as material. Working with the tree is definitely easier, but metal beds have a special style and sophistication, which, of course, cannot be said about wooden structures.

Please note that for independent manufacture of a metal bed can not do without special equipment. With the acquisition of materials, there are most often no difficulties, since they are all commercially available. But as for the equipment, it is not for everyone in the house there is such a way, and the skills of working with welding are not available for each wizard.

Start need from welding frame design bed. When this operation comes to an end, you can make the back of the backs. The backs can also be made independently, but can be ordered in a special workshop, especially if it is a forged option. Homemade workshop to make such exactly will not allow. As noted above, the beds with forged elements look especially elegantly and exquisitely. Simply put, having a huge desire and opportunities, you can easily handle such a task as the manufacture of a metal bed.

Back to the category

What are there metal beds?

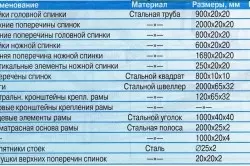

Materials that are needed to build a conventional metal bed.

Article on the topic: How to paint the fridge with your own hands?

The production of metal products of this species stepped far ahead compared to the past century. Types of systems are very diverse and differ in both their intended and in the number of beds (tiers), and the size of the design and design also have many differences.

Factory metal beds are most often intended for two categories of people: children and adults. Depending on which the design is intended, it has its own characteristics and characteristics.

- For example, the difference between the children's bed from adult primarily consists in size. Its length and width are few instances for adults. Most often, the length and width indicators correspond to the following values, respectively - 1.5 and 1 m.

- Modern manufacturers offer products even for newborns. Naturally, the device of such models is characterized by special safety and has higher sides, legs and other features. However, at the moment they are not very popular.

- The variant of the children's system can have one or two floors. Bunk devices love all kids very much, and if you have two children, then such a bed from metal with your own hands will become a welcome gift for them. The appearance of the bunk metallic design can be very attractive, and everything knows about its strength. For convenient lifting to the second tier, the device is equipped with a special safe ladder.

- The dimensions of metal structures for adults are much more diverse children's. These can be single-sized systems having a size of 2x1 m, half-band, the size of which is already 2x1.4 m, and the double, length and width of which varies from 2-2.2x1.8 m. Choose the desired will not be difficult.

- One person is easily located on the single-sighted one, a large adult man or an adult medium size with a child will fit on the space. The double option is able to provide a comfortable sleep with two adults. If you want to get a non-standard size, then it is best to choose custom-made manufacturing on an individual project.

Back to the category

Some classification information

Another classification of metal beds implies the difference in the type of construction. These are elements of a prefabricated nature and welded manufacturing. The bed, with their own hands, made using welding, has a monolithic design, in the inner space of which is placed specially made frame. You can buy a mattress separately or order it according to your standards.

The system of a prefabricated nature consists of separate parts: sideboards, backs, legs, fasteners. This option is considered more convenient in terms of transportation and movement in the apartment. But in strength, it can give up a little by the option described above.

Now you know a lot about metal beds, and choose the appropriate option for you will not be difficult. Maybe you will decide on an independent manufacture of a metal model and as a result you will acquire the subject of pride in the bedroom interior.