At the moment, the beams for alignment of the floor are rightfully considered to be a key element to create an ideal level. As a rule, the slabs of overlaps in modern apartment buildings are characterized by various irregularities, depressions and influx, as a result of which the functional outdoor material is practically impossible for them. Using the mentioned product, you can quickly correct the defects of the structure by performing a high-quality screed for the lowest possible period of time.

Types of lighthouses and the features of their use

At the moment there are several options for beacons to equalize the base, each of which has its own unique specifics of application. The list of current species of the considered products includes:

- Lighthouses from wooden bars;

- Beacons made of steel rolling pipes;

- Lighthouses from the slide of the solution for a screed;

- Lighthouses from industrial P-shaped or T-shaped profiles, etc.

Perhaps the most commonly used products for alignment of the floor with their own hands became wooden bars, the thickness of which should be at least 3 cm. The installation of such products will require large physical costs, since wooden wedges fixed with screws are put on the bottom of the bars under the bars. With this method you need to pre-wet wood, otherwise it will negatively affect the concrete solution. At the end of the fill and frozen the mixture, the bars are necessarily taken out of the screed, closeing the emptiness by the remaining solution.

High-strength lighthouses from steel rolling pipes are indispensable when the heavy screed is arranged in huge premises. Standard products simply do not withstand tons of solution, because the thickness of the base here can reach tens of centimeters. The height of the pipes is adjustable with the pressure in the screed or lining the mixture in places where the level of the product is slightly underestimated.

Article on the topic: Wall cladding panels from DVP - 3 ways

How to put lighthouses from the slide of the solution, knows not every expert on the screed, however, this method is also relevant when leveling the base with a semi-dry mixture. Initially, in the corners of the room lay down the slides of the wet solution, which are aligned relative to the zero mark. The distance between them should be at least the length of the rule, which will make it easier to facilitate the installation of the base. After frozen, the hills between them consistently distribute the screed solution.

What is an industrial product?

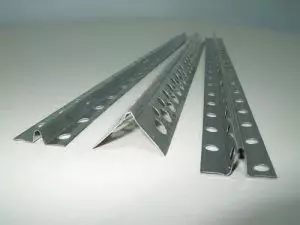

Today, the main task that industrial lighthouses is performed to align the floor is the designation on the repair surface and maintaining the same level on its entire plane corresponding to the zero line relative to the horizon. In the construction sector, various methods of installing a level using the presented product name are used, while the lighthouses themselves do not differ much from each other. Externally, they are P or T-shaped oblong plates manufactured mainly from aluminum alloy. Each product has several round holes for mounting the plate to the surface of the base.

Lighthouses for alignment of sex are resistant to corrosion, which allows you to extend their service life of up to several decades. High resistance to aggressive acid-alkaline media gave the opportunity to leave such products in the cement mortar after its complete solidification. They absolutely do not lose design, and if necessary, they can be easily removed from the solution.

Key principles of lighting installation

To create a perfectly level basis with the help of the products under consideration, always follow the following key principles:

- accurate setting "zero" level;

- Compliance with the set distance between the guides.

The "zero" level bevel is one of the most difficult measures from which the final success of the solution of the solution directly depends. It should be remembered that to create a durable reliable base, its thickness on the narrow site should not be less than 3 cm. With a dry screed, this indicator can be increased to 5 cm depending on the construction features of the room. As a result, the values mentioned are initially taken as a guide to determine the zero level.

Article on the topic: Soft windows for arbors: Features, Advantages and Disadvantages

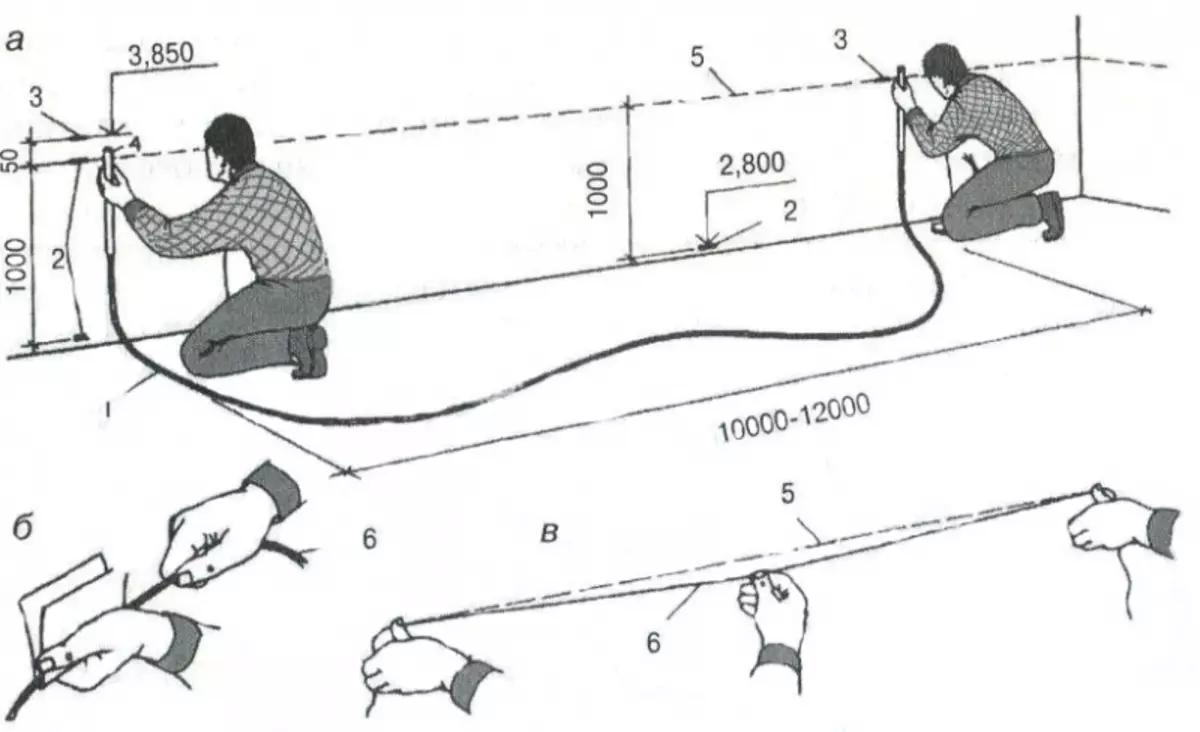

Since the exhibition of beacons is made by zero level, then it is necessary to refer to his debug. Initially, in the highest corner with the help of a construction roulette, a distance of 100 cm from the floor is measured, after which the moisture-proof marker or pencil is made. Next, through the construction level, this mark is neatly transferred to all the remaining three corners of the room. The process will significantly accelerate if the marks are denoted using a functional laser pointer.

We measure the distance from the bound level to the base

From the obtained horizontal line, the distance is measured to the base on all parts of the floor covering, and the place where this indicator will be minimal, will become the highest point of the surface being created. It makes a mark, which should be higher than the floor level of 3 cm, and then four level lines in different angles of the room are carried out from this designation. This will be a professionally exposed "zero" level from which it is necessary to repel when installing beacons.

How to keep the distance between the beacons?

High-quality lighting implies compliance with a strictly defined distance between them. Product data lines are located along the room, in the direction of the future fill of the base. At the same time, the first parallel wall surface of the guide is obliged to be exhibited at a distance of no more than 300 mm, otherwise the failures of the floor surface are inevitable. The remaining lighthouses for alignment of the floor are evenly mounted at a distance of about 200-300 mm from each other. With a dry screed beacon with the help of fastening elements, they are mounted at a sufficiently close distance constituting approximately 150-200 mm from each other (but at least 7 pieces for every 3 meters of room length).Features of the fill of the solution

If the question of how to put lighthouses is considered to be one of the most difficult, the process of creating a solid foundation for properly exhibited guides will not cause absolutely no difficulties. The cooked solution with a reserve is neatly laid out in the recess between the two rows of beacons, ranging from the wall. Next, using the Rules, the mixture is consistently pressed against the beacons throughout the perimeter of the room, comparing the screed with the "zero" level. Excess composition is evenly distributed over the area of repair work. With a qualitatively mixed solution, the process of creating a base for the floor will not make much time, and a flat surface will certainly serve not one decade.

Article on the topic: Warming of balcony plastic doors for the winter

Thus, the installation of lighthouses for the floor is key to the construction of a wear-resistant design, which will be perfectly even and eats for a long time without losing its functionality.