Malnock on the Ryabik do it yourself (2 options)

Option number 1.

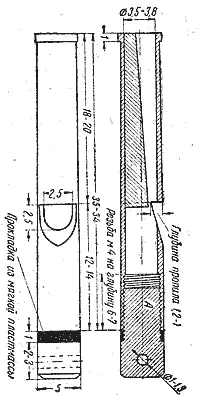

The peeper is made of bone, plastic or silver tube with a diameter of 5 mm (outer) and 3.5 - 3.8 mm (internal). Its length 34-25 mm. Insert and plug with a thread and a hole for fastening the food to the lace is best made from plastics.

Between the cork and the casing of the food (for greater density), the laying of soft plastic or solid leather with a thickness of 1 - 2 mm. All the mannock is thus made of four parts: tubes with a hole (housing), liner, gaskets and threaded tubes.

The procedure for manufacturing and assembling the manka is simple. First, from one end of the tube inside the thread M-4 is cut into a depth of 6-7 mm. Then the hole with a diameter of 2.5 mm is cut or drilled; The front edge is located at a distance of 12-14 mm from the bottom end of the tube. Then the liner is cut and inserted and checked for the purity of the sound. For this, the lower end of the tube closes with a finger and air is supplied to the meter. The sound should be clean, without hiss, however, relatively low. After that, the gasket is done and put on a plug, the plug is screwed into the bottom end of the tube and (by changing the length of the screwed part of the cork), the kitchen setting is performed. The volume of the chamber is changed with the rotation of the test tube, which corresponduously changes the height of the sound. Unscrew the cork, the peeler's needed is easy to clean.

The manock proposed by me has proven itself very reliable and trouble-free in work.

Option number 2.

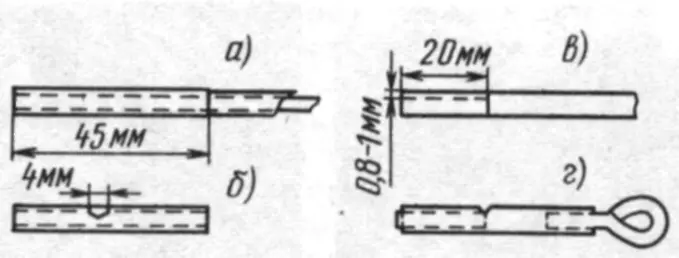

I decided to share my experience in making a gun on a ripper. In life and on the pages of the magazine, I did not meet such a manka: maybe someone will come in handy. For this, it is necessary only a piece of aluminum wire with white insulation with a cross section of 4 mm, a knife, pliers and a file. I measure the length of 45 mm from the end, make an incision around the wire, remove the insulation (Fig. A). Measure 20 mm from any edge of isolation and make an oblique incision on both sides of 4 mm wide (Fig. B). Then a sharp knife from the pulled wire to cut off a piece of 20 mm long, after removing the edge of 0.8-1 mm at the same length, cut the buns with a file and insert a whistle into the front of the future so that the screw coincided with the edge (Fig. B).

Article on the topic: Substitution of the membrane in a hydroaccumulator

Next, from a piece of wire with a length of 35 mm, a ring of an inner diameter of 5 mm is made, and the rod is inserted into the back of the whistle, with which the frequency of the sound is adjusted (Fig. D).

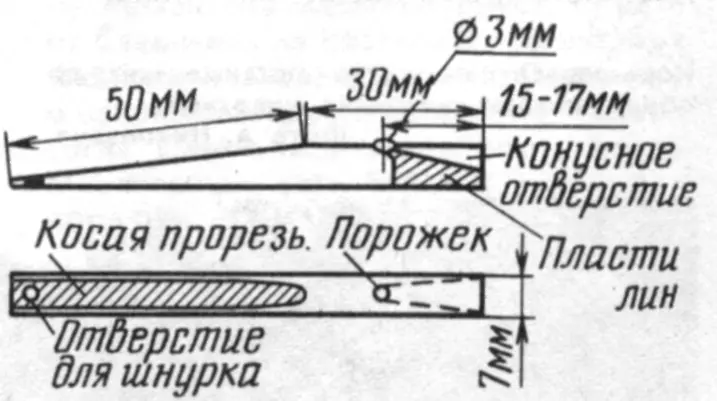

I make a plank on a row from an ordinary ballpoint handle. I take her longer half, with a wider hand cutting off the thread, and a narrower stage with a file to obtain a long slot, which is limited to the width of the walls. Rates 15-17 mm from a wide end, drill a hole with a diameter of 3 mm. Then I take a piece of smelting or plasticine and lay inside the manka. Then with a needle or sharpened match I do a conical hole in the plasticine. In this case, it turns out the thresholds, which must be accurately correct. Volume and purity of whistles depend on the state of the thoring. It remains to make a hole for a lace - and the shock is ready. This mancock can be licking both male and female. It is only a slightly cover with your finger to the slot, and the shutter will sound low, like whistles the female of the ripper.