Eh, the bathhouse, as well, sometimes sometimes sit in the steam room, will relax, but it will not be able to do if it is difficult to maintain the desired temperature. This occurs in most cases due to poor thermal insulation or violation of technology when it is installed. How to carry out the insulation of the walls of the bath from the inside, so that nothing can overshadow the joy of visiting the parley? The answer to this question I'm just going to give in this article. Read, do not be distracted.

Advantages of internal insulation

Yes, yes, we will talk exactly about internal insulation, since this method has thorough advantages over the insulation of the bath outside. Such benefits to mind comes at least three.

The first is the ability to reduce heat losses in the already constructed bath, but when the evaluation of which, errors were allowed when the foundation is insulated. This defect cannot be corrected, insulating the building outside, as the heat will go through the floor, and it can be isolated, only from the inside.

The second advantage is purely economic. The insulation of the bath from the inside requires much fewer materials than the complete covering with thermal insulation and the facing of the whole building - the area of work is much less. In addition, insulating a bath from the inside, often the main work is carried out only in the steam room, which is even less in size.

Of course, other rooms, such as the locker room, the shower, too, should be insulated, but the degree of consumption of material on them is many times less than on the steam room, therefore, and the money is much less money.

The third advantage enters into force only if the winter in your region is particularly harsh. In this case, the bath must be insulated both outside and inside, especially if the building is built out of a brick or aerated concrete. Even the bathroom bows, which are known for their thermal insulation properties without special treatment, will not cost such a cable without additional internal thermal insulation.

Selection of material for insulation

At the moment, the construction market presents a huge number of different insulation, for walls. But not all of them are suitable for the bath. Separate heat insulation, it is necessary based on two facts:

- The conditions in which heat insulation will fall;

- Characteristics of the heat insulating material.

First fact - operating conditions. In the bath, they are more than aggressive, high humidity and temperature. The large differences, especially in winter. From the side of the street on the insulation will "push" frost, and on the other hand, the heat. Such a combination will inevitably lead to condensate.

Article on the topic: Septicchka do-it-yourself for a private house: device, how to make it right, video

In addition, high temperatures, turns many popular insulation into dangerous to human health. Also, do not forget that the bath is a building of an increased risk of fire, so you do not need to warm it with materials that are well burning.

As for the characteristics of the material, they must comply with the same operational conditions. In order to be clearer, I will give an example of thermal insulation, which is not worth using when bathing a bath. This material is Eco. Yes, it is an excellent heat insulator, but its tendency to the accumulation of moisture, all spoils. When eco-friendly, wet, it loses its properties.

What materials can not be used to insulate the bath?

In addition to eco-houses, it should be taboo to do the insulation of the walls of the baths from the inside using, foamflast, other materials based on it, such as Penoplex, and also forget about the use of classic mineral wool as insulation. I explain why they are not suitable.

Polyfoam and all its derivatives at high temperatures are beginning to highlight harmful substances that can lead to suffocation, in the conditions of the steam room, you can not even notice. In addition, the foam is perfectly burning, which is not good.

As a binder in a classic mineral wool, formaldehyde resins are used, their pairs are devoted to humans. Yes, all manufacturers declare that these evaporations do not exceed the norms. But who, what is the case, if this is the norm of poison. And the same, this norm stands out under normal conditions, and the bath is not different.

What materials are suitable for insulation?

Among the recommended insulation, you can allocate:

- Peat blocks;

- Sawdust;

- Fiberboard;

- Foam glass;

- Minvat on acrylic basis.

Peat blocks. This is an ordinary peat mixed with a natural filler, such as sawdust or straw. From these materials make "porridge" by bringing it in water, with the help of forms and press, blocks produce. They do not rot, do not burn, perfectly absorb, and also give moisture back. Have good warmth and sound insulation.

Sawdust is an ordinary waste of production during the sawing of wood. Despite the minor sizes, it is still wood, and it has good thermal insulation. The wall in the bath is insulating with the descriptions, falling asleep them in the niches that are pre-covered with a parobararier and waterproofing.

Fiberboard - wood fibrous plates, are nothing but pressed wood chip. They have fairly mediocre heat insulation, but at the same time they are inexpensive.

Article on the topic: How to hide the wires on the floor in the plinth?

Foamglass. As it is clear from the name of the foam glass, it is a foamed glass with excellent characteristics of thermal insulation. Does not highlight harmful substances, does not burn, indifferent to moisture. In my opinion, the foam glass is the best option for the insulation of the bath, but there is a flaw, like any other good product, the price of it "bites". But if the question of saving for you is not worth an edge, then choose foam glass, you will not regret.

Minvat on acrylic basis. These are the same mineral wool slabs, with practically the same characteristics, but not distinguishing harmful substances. All because the binder is not formaldehyde, but an acrylic resin, which is absolutely inert, to any chemical compounds and temperature drops.

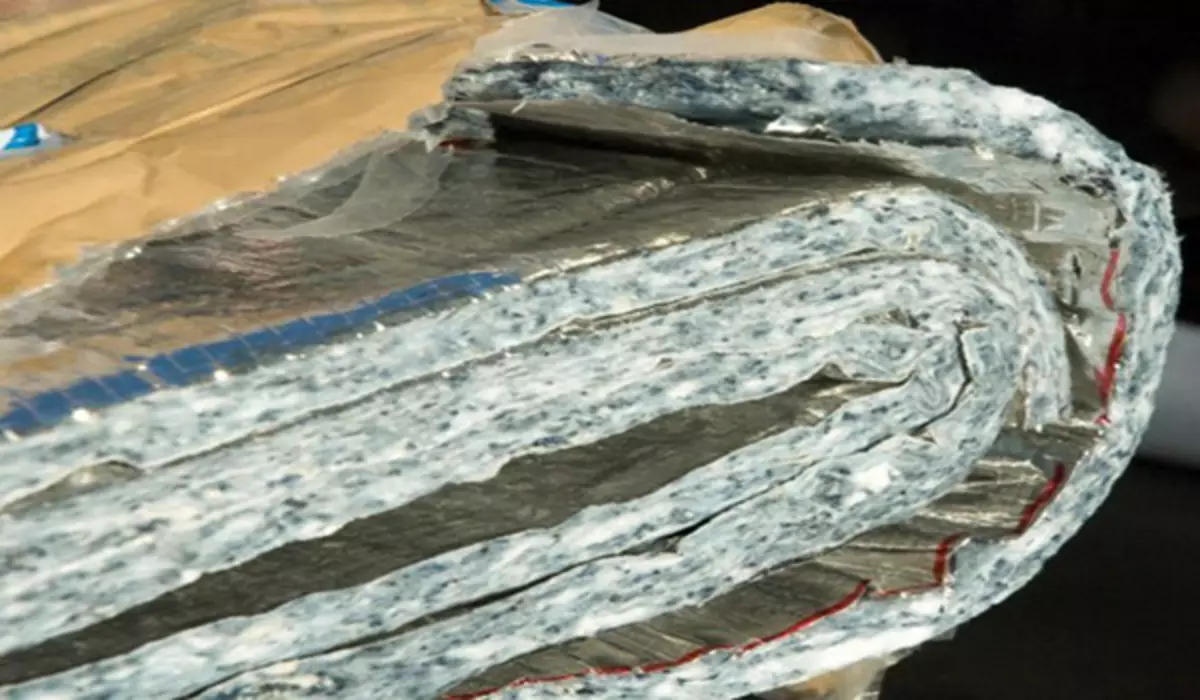

Technology of insulation "Pie"

This technology has such a name due to several layers, which consists of a wall after the completion of warming work. The first layer is the carrier wall, the second is the insulation, the third - the parobararier, and the fourth is the facing of the wall, which the wooden lining is usually performed in the bath. To become clear how to act according to this technology, I will cite an example, as a bath can be insulated, mineral wool on acrylic resin.

Technology provides to begin insulation, from the ceiling and finish the floor. Begins "Pie" from installation on the surface of wooden bars. They will serve as a basis for mounting the plates of Minvati, which, by the way, will be attached by the versius, without using any additional fasteners.

So that the insulation plates reliably stood in their place, the distance between wooden frame bar must be 1 cm less than the width of the insulation, only in this case can be sure that the insulation will not fall. After the frame is ready, you can begin to fill it with heat insulation. Make sure that when installing, the edges of the mats are not finished, as it can negatively affect its properties.

Important: When mounting the insulation, all its components should fit tightly to each other. This is also necessary because if the gap remains between the plates, the moisture will accumulate in this place, and the so-called cold bridge is formed through which heat will go.

After mounting the insulation, it needs to be covered with vaporizolation. In his role, traditional runneroid or more modern foil parobacres can be. The party that is covered with foil should "look inside the room to reflect warmly back. All seams and joints of vaporizolata, it is necessary to seal, using aluminum tape.

Article on the topic: Location and calculation of reinforcement in the tape foundation

Further, after all the seams of vaporizolata became sealed, you can begin to make a crate, over vapor barrier, on the fiber frame of the frame. When installing, consider that the distance between the parobararier and the future facing should be at least 5 cm. It is necessary for condensate freely glasses, otherwise it will fall on the lining, which due to this quickly rotates.

Features of warning steam room

The main feature of the heat insulation is the concentration of the insulation in this room compared to others. Since the pair, it is the main room of the bath, here you need to create conditions so that as much heat can remain in the room, and at the same time provide good ventilation.

To warm the steam room on the conscience, as already mentioned, you need to use high-quality thermal insulation, and comply with its installation technology at all stages, from the preparation of the surface and installation of the frame, until the last stage, wall cladding with wooden lining. Once again I would like to emphasize the importance of the good sealing of the seams of the parobamire and the tight laying of isolation.

Sometimes it is permissible to use multiple layers of the insulation, but even in this case, do not forget that you need to leave the airspace between the parobararier and the finishing wall facing.

Floor and roof ceiling insulation

The thermal insulation of all surfaces in the bath, technologically, has a little differences. They are only in several nuances, and the main rules are relevant for both walls and a floor with a roof.

For example, as already mentioned, the insulation of the bath begins on top, that is, from the roof and ends with the floor, there are several reasons for it. First, it is more convenient to agree, it is easier to descend down to rush down, than to throw from the wall to the roof, and after the floor.

Secondly, all surfaces must have homogeneous thermal insulation. That is, thermal insulating materials should, tightly lay down to the same elements, but already on a different surface, the parobararrier must go over the overst to the next surface.

For example, the thermal insulation of the roof and the ceiling should be seamless to each other, the parobararier on the ceiling falls over the adhesion to the walls, in order to further connect it with vapor barrier on the wall using aluminum scotch.

In turn, thermal insulation and parobarar of the walls are connected in the same way with the floor. Observing this technology, it turns out to achieve uniformity of thermal insulation and complete sealing of the room so that steam does not leave the room. The latter is especially true for the wage.

Video "We are wearing a bath from the inside"

Video with an explanation of the stages of work on the example of a bath with an already mounted frame and almost ready-made surfaces to the insulation mounting.