The accumulated construction experience allows not only to build objects that meet the special requirements of the temperature and humidity regime, but also provide for certain protection of premises in the event of a fire situation.

Partitions from fire-resistant drywall are capable of providing a certain protection of premises in the event of a fire situation.

For this purpose, special fireproof screens are used, which includes and plasterboard partitions marked as GKLO. This type of drywall is characterized as a material with increased refractory. The letters of this abbreviation are decrypted as:

- "G" - gypsum;

- "K" - cardboard;

- "L" - leaf;

- "Oh" - fire-resistant.

Recall that there are still plasterboard sheets of three types:

- Ordinary - Glk.

- Moisture-proof - G Clac.

- Moisture-resistant, with an increased resistance to open flame - Glevo.

What is the difference between a refractory sheet from the usual?

Types of plasterboard, scope and their color marking.

In conventional GLC, the cardboard serves as a kind of frame, which, when fire, begins charring, but at the same time the plaster is not destroyed yet. As soon as the fire is gaining strength and cardboard burns to the end, the gypsum is deprived of the frame and drywall terrestors lose their strength and scatter.

The fire-resistant design of the drywall is as a core reinforcing fiberglass, reinforced clay, which includes about 20% (from the total weight) of crystallized water. This explains the long-term resistance of fire and the preservation of the strength of GKLO in the event of a fire, which for fire and technical classification is the characteristic of the limit of fire resistance.

The limit fire resistance for building structures is determined by moments during which the signs of limit states are preserved, such as:

- Losses of carrier abilities.

- Losses of thermal insulating ability.

- Loss of integrity.

Plasterboard partitions can save fire prevention properties of 25 minutes and only after 45-55 minutes will be destroyed under the direct influence of fire. These sheets, as well as GLC gray, are marked with a red marker.

Comparative table of fire resistance of plasterboard partitions.

Features of the installation GKLO:

- As for all GLCs, before starting the installation work, it is necessary that the fire-fighting plasterboard after transportation lay at least three days in a horizontal position in the room where it will be mounted. This condition is necessary to complete sheet surface alignment so that there are no problems with the installation and fitting partition in the future.

- The next common for all GLC stage is the markup of the design or planned position of the plasterboard.

- Setting the frame for fastening sheets and fixing the fire-resistant partition to it.

- To create a close contact between adjacent GKLO, all its edges must be processed, that is, the end is cut on one third of the sheet thickness, which ensures the practical invisibility of the connecting seams. And this guarantees the savings of finishing materials.

- One of the main points in the installation of GLC is the compound of partition and building elements.

Article on the topic: Dryer for linen with your own hands

Some recommendations for assembly work

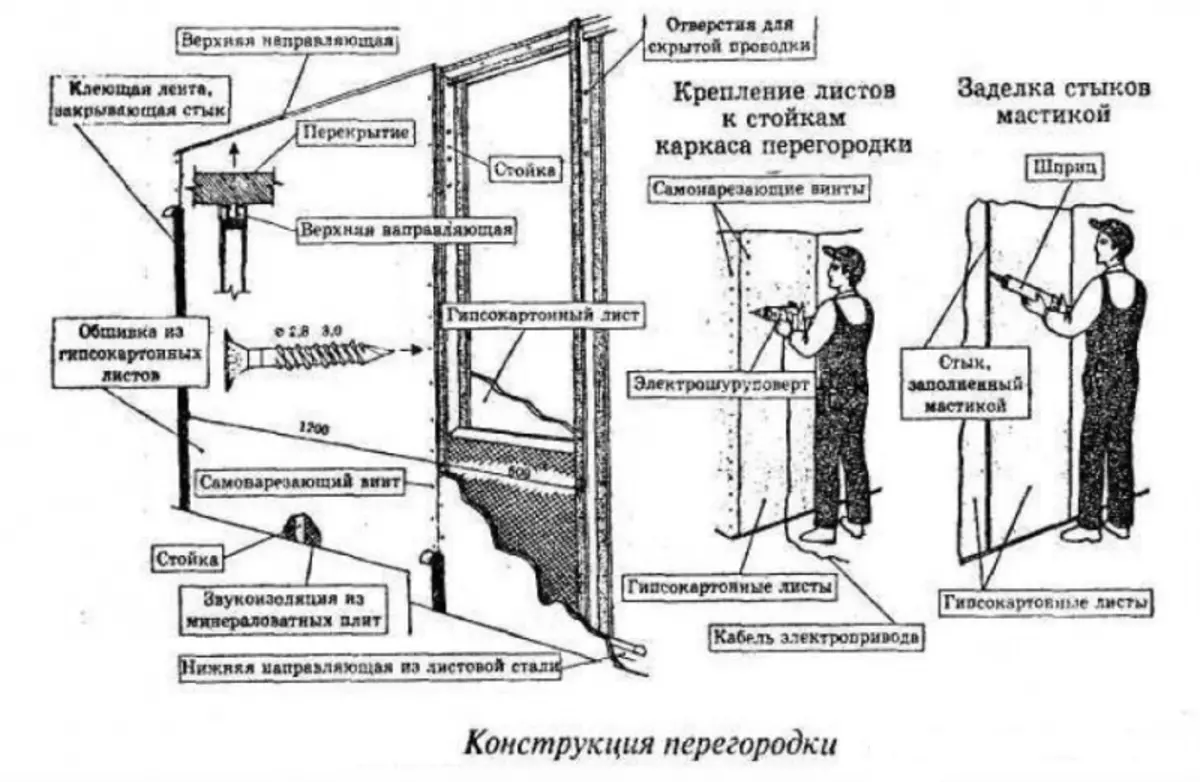

It is obvious that only the ability of GKLO partitions is quite effectively resisting open fire, will not provide the required limit of fire resistance of the fence. To do this, the entire set of activities, aimed at complying with fire safety standards, during the construction of residential premises. This is especially true when arranging objects that need increased compliance with fire safety rules. Such objects include kindergartens, schools, hospitals, hotels, restaurants and other premises of the massacre of people.So, for fire hazardous premises is not allowed to install GKLO onto a wooden crate, even if it is impregnated with antipirens. To do this, metal frameworks with rack profiles should be used (not ceiling). In this, the fastening of the sheets is made by self-reserves at a distance of no more than 20 cm.

If there are vertical communication mines in the room, then they must be additionally insulated with non-combustible materials, such as mineral wool slabs with foil. These plates are laid between the profile elements that are covered with adhesive soundproofing ribbon. After installing GKLO, angular joints are closed, strengthened with corner profiles.

Separately, we will focus on such an urgent issue as the docking of engineering communications and drywall with an increased fire resistance limit.

Rules for pairing engineering networks and drywall structures

Mounting scheme for plasterboard plasterboard.

As a rule, during the construction and repair work, the next stage of the construction of capital walls is the laying of engineering communications: water supply, sewer, gas pipes and power grids. And then the installation of interior partitions and wall decoration begins. The appearance in the construction production of plasterboard made it possible to lay engineering communications directly in the body of enclosing structures . Consequently, now the installation of communications and drywall structures is performed simultaneously.

All this happens in the following sequence:

- The framing holes or other additional framework elements are installed in the partition cavity.

- Enhanced plasterboard transverse additional frame element.

- All conjugation joints are carefully sealed.

When conjugate partition from GKLO, having fire resistance of more than 0.5 hours, with pipelines, the diameter of which exceeds 60 mm, it is necessary to organize the insulation of the pipelines by means of the installation of a separate housing having fire resistance is equivalent, that is 0.5 hours. The length of this cladding from the septum plane must be at least 0.5 m.

Article on the topic: What glue is better to glue the ceiling tile

The design of this casing is performed for each intersection separately in accordance with the developed project and taking into account thermal insulation on pipelines. And it is installed (casing) before mounting the partition. If there is a pairing with a pipeline having a diameter of less than 60 mm, then neither the device of the casing nor the additional frame in the facing is required.

Diagram of mounting pipes for plasterboard.

In place of pairing a fire-resistant partition of GLCs with heating, cold and hot water pipelines, it is necessary to install a sleeve of non-aggravated materials, which will ensure the free movement of the pipeline in the event of a change in the coolant temperature. Installed sleeves at the pure floor mark +0.03 m.

If a group crossing of drywall pipelines occurs, the use of general casing is allowed. But in any case, the fireproof standards prohibit the adjoining of the close pipeline and partitions.

For lining of the pipeline should be used fire-resistant plasterboard. The hermetic fitting of the guide metal is provided by fixing the sealing tape to the pipeline. After that, the profile is fastened to the surface of the base with a self-tapping screw on a slot dowel in a step of no more than 0.8 m.

Electrical wiring in drywall cavities is laid on the project and according to the rules of the device of electrical installations (PUE), for which submersers, electrical and branching boxes used for hollow walls with a certificate of conformity are used.

Electrical cables, wires, cords, sockets and the like fittings weaken the fire resistance of GKL and its sound insulation characteristics, so it is necessary on the reverse side of the box for electrical equipment to isolate with a gypsum solution, a sound insulation material or specially made from drywall of small boxes.

Montage Guide

To perform a mounting partition from drywall, you will need the following tool:

- screwdriver;

- drill;

- cutter for plasterboard;

- Scissors or cutter for metal;

- roulette;

- level;

- a hammer;

- mounted gun;

- planer for cutting edges;

- Rubbing planer;

- A riveter for GLC profile.

Perforator, screwdriver, construction level, roulette, square, marker and pencil, grinder with discs, scissors for metal, knife for cutting plasterboard.

Of the concomitant materials:

- plumb;

- Milling cord;

- the pencils;

- Fixture for fixing GLC;

- Construction markers.

Materials used:

- Soundproofing tape;

- Sealing tape;

- dowels 35x5 mm;

- Self-tapping screws 9x3.5 mm, 25x3.5 mm.

Installation of the partition is performed before the device of clean floors, at a temperature not lower than + 100 ° C. Design markup is made using the level and cordable device on the walls, floor, on the ceiling. On the floor of the floor, the location of the rack profiles and profiles (racks) is noted for door openings.

Profiles are cut off with electric or manual metal scissors. For better sound insulation, a sound insulation tape of the corresponding width is pasted for the entire length of the guide profile. The guide profiles using dowels with a length of 35 mm and a diameter of 5 mm (35x5) are attached to the floor with a hammer, or drilling, or a mounting gun. Between points of attachment, the distance should be no more than 1 meter, but not less than 3 mounts for one profile.

Article on the topic: Mastery blinds for the balcony with your own hands: Economical option for windows

Detailed installation scheme of plasterboard rose.

A similar fastening is made on the ceiling. Then the height of the rack profiles is measured. The rack profiles are cut in size so that their length, like the length of the GLC, was 10 mm less than the height of the room.

On profiles, adjacent to the walls, glue sealing tape. If they are attached to drywall partitions, then self-tapping screws into the rack profiles, and if brick or concrete walls, then a dowel with a length of 35x5 mm.

For the device of the door leaf, if the weight of the web is not more than 30 kg, the reference racks for the box can be made of 2-racks, by putting together in each other, "backs" outwards. They are installed in the guide profiles and are attached to their self-tapping screws 9x3.5 mm.

Next, the horizontal jumper is cut from the guide profile, the width of the doorway is bent in the form of the letter "P" and is fixed with self-tapping screws. If the GLC is completely overlaps the box, then one intermediate rack above the door frame is installed, if not entirely, then 2 racks.

The riveter for the profile of the rack is mounted in the guide profiles of the spacing with a bend. Here will be the joints of the adjacent sheets. Further, with a pitch of 600 mm, the rails are placed in the guide profiles and fixed by the spin with a bend, but their backs should be addressed in one direction.

Cutting sheet, you must first cut the cardboard with a knife and part of the gypsum core, and then over the line of the outbreak and cut the cardboard on the other side. The edge of the sheet to be treated by a relief ruble, and then on the end side of the sheet to make the edge chamchair at 22.50 by 2/3 of the sheet thickness.

GLK, with an end faban at the ceiling, using fixture for fixing, presses to the frame and fastened with a step of no more than 250 mm self-tapping screws 25x3.5 mm screws screwed from the center to the edge of the sheet or from the corner to the side, and from the edge of the cropped edge - by 10-15 mm.

The shift of screws vertically on 2 adjacent sheets is not allowed by more than 10 mm, they must enter the GLC at an angle of 900 and penetrate into the frame profile to a depth of 10 mm and more. Screwing heads, taking into account the subsequent putty, are settled to a depth of at least 1 mm.