Wooden floors arrange not only in wood houses, but also in brick buildings. Such a floor looks great and helps to create a good microclimate indoors. Styling the wooden floor is easy to perform with your own hands, even if there are minimal carpentry skills. But at the same time, it will be necessary to prepare in theoretical plan and consider the most important moments of the upcoming work.

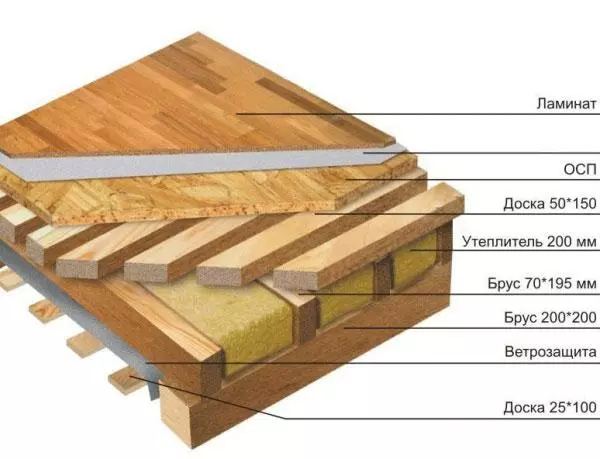

Wood floor circuit.

There are many options for wooden flooring. Choose them depending on certain conditions of construction, where the flooring has to be done. Most often stop at such versions:

- The floor with the installation of rough and insulating layers, which is located on the ground or beams of overlapping.

- Wood floor on a concrete basis with a warming layer.

Model options for building floors with lags.

Number one option is commonly used by owners of own homes. In this way, you can arrange the floor as a ground-based basis in the basement or on the first floor and on other floors in the form of overlapping on the beams.

Option The second involves the manufacture of a concrete screed as a basis for the floor. It can also serve as the slabs of overlapping from reinforced concrete. The design of the floor can be significantly changed and improved that not only facilitate installation, but also make it cheaper.

General Wood Floor Arrangement Terms

Work on the construction of sex is better to exercise better when the heating season ends. During this period, it is less likely that wooden materials are absorbed by moisture, which will later be harmful to affect their quality. If work is decided to spend in the summer, it is necessary to try to wait for the moment when over the past tenfig days is good, dry and sunny weather.

Article on the topic: Original ideas for flower beds

Like another wood, intended for use in construction, lumber should be treated with antiseptics, antipirens.

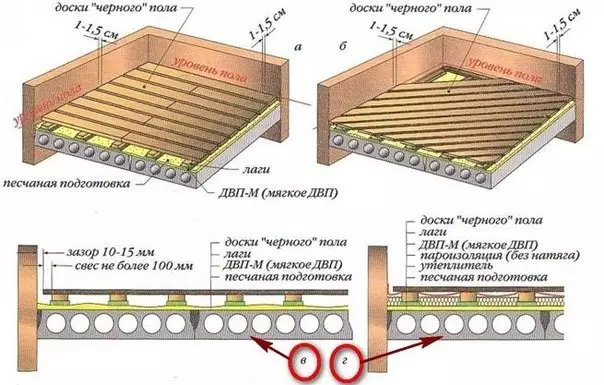

Diagram of the black floor device.

Materials for wood flooring:

- Board of glued timber;

- Sheet material - for example, plywood, chipboard;

- uncircumcised board;

- Folded board.

Of the uncircumcised boards and sheet materials make flooring for roughing. Later will be laid out the flooring. The folded board and glued timber material are used to form a pure layer, which will need to be painted or varnished.

Preparation of the foundation

If the wooden floor is planned to be laid on the ground, a reliable strengthening of lags should be ensured.

There is a device for waterproofing space under the floor, it is necessary to take care of both insulation.

The basis is prepared - for this, the ground is removed on the entire perimeter of the room, so that the thickness can be inserted into 20 cm below the ground level. A layer of rubble and a layer of river sand are poured on the prepared foundation, wet water and tram.

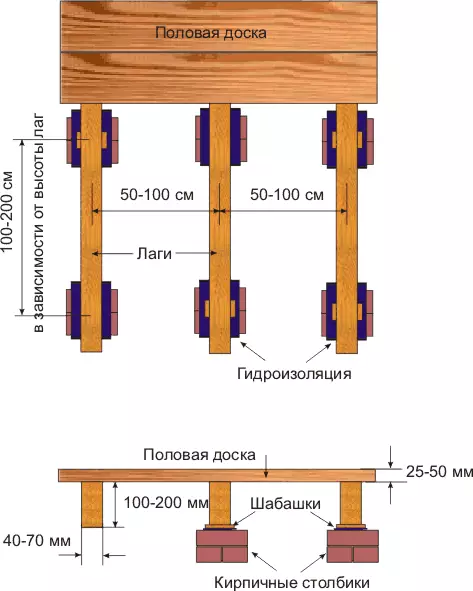

Lags for wooden floor.

On this basis, several brick columns are installed, which will serve as a support for lags. The width of this column should be two bricks, the height is 20-40 cm. Bricks are fastening with the help of a conventional cement solution, they are built on top to one level. It is necessary to take into account that each of the lags should have the smaller two pillars, which will be located at the edges.

For long lags add pillars in the middle. The distance between them is calculated depending on the size of the boards for lags and the planned settlement load. To compile calculations, it is better to turn to professional designers.

When laying building materials on beams located between floors, it will not be necessary to prepare. On this basis, you can immediately begin to distribute lags.

Article on the topic: wall decoration with decorative stone with their own hands (photo) decor walls stone

Over the beams or pillars put the rolled waterproofing material. After that, they are put on special woods made of wood prepared by lags and anchors fasten them to columns. The upper face of the lags with the help of a plane is derived in a single plane. The extreme lags are built up with the help of a level, between them stretch the fishing line, after which the rest are stacked.

The details for the construction of the draft floor are attached to the bottom of the lags. For the base in the form of soil and lags on the pods, the bars are fixed across, along the entire length of the room. When laying on the beams, to nail the bars to the sidewalls of lags on both parties. For insulation take vapor-permeable materials - for example, minvatu, plates from basalt. They are inserted into the gaps between the lags so that no gaps remain.

Before laying a wooden floor lay a vapor-hydro insulation membrane. It must be stacked with the allen 20 cm, the joints of the material are well cleaned with scotch. Fastening will depend on what the finish coating is selected. For example, under the boards made specifically for the floor, with the presence of a ventilation gutter, the rails for fasteners are not necessary.

Concrete floor base

Much easier to install wooden floors based on concrete. Lags can be installed with a greater frequency, which will reduce the bending load. Align such lags are much more convenient. A permissible step for lags with a thickness of 20 mm when installing on a concrete base is considered to be 30 cm. For boards with a thickness of 25 mm. Step should be withstanding 40 cm. To fix them, they will need construction studs with a diameter of 8-10 cm. The holes for them are drilled in the bars.

After the lags are aligned and secured, starting laying boards. For fixing it is better to use selflessness.

At the end of the work when all the boards are posted on the floor, finishing finish. It can be grinding, cycloying, paint and varnish coating.

Article on the topic: Formwork for foundation: how to make and install + ways to save