Linoleum is an outdoor material that does not lose its popularity for many years. It is used for styling not only in residential, but also office space, is distinguished by a long service life, good characteristics, and its installation is extremely simple. Laying such an outdoor coating can be carried out on any type of foundation. For example, in urban apartments usually laying is performed on concrete. Floor preparation to laying includes several stages. Most often this alignment, flooring a special substrate, which makes the base warmer, more comfortable and more durable.

Preparation of the solution.

Preparation of a draft base base

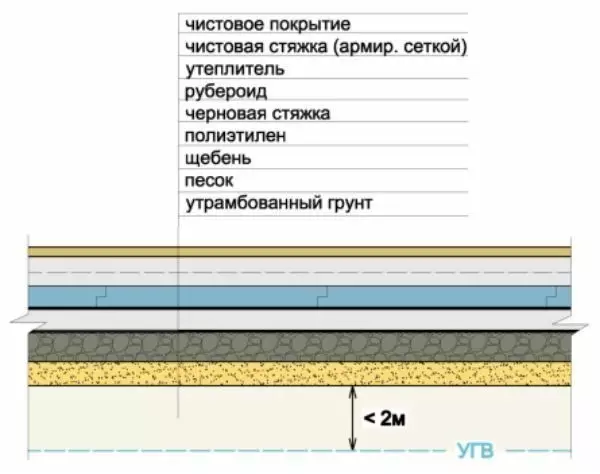

Preparation of concrete floor under linoleum laying should include a whole range of work. Most often, the base is made from reinforced concrete plates that need not only in insulation, but also waterproofing.

Floor Filling Scheme.

Priority of work:

- Reinforced concrete floor plates, if necessary, are aligned using a cement-mortar filling.

- Organize sound, thermal insulation of fiberglass or mineral wool slabs.

- Waterproofing can be made of pergamine, roofing, special membrane, polyethylene film.

- If the plates are significant, then a layer of cement-sand screed is applied, the thickness of which depends on the works already produced. For example, a layer with a thickness of 20 mm is placed on a conventional slab, and the insulation is 40 mm.

- Linoleum laying is performed, the thickness of which should be 3-6 mm. Often, a special substrate is laid under linoleum, which increases the comfort of the use of floor covering.

Concrete base for work is preparing simply:

- First, it is necessary to examine its surface, determine which particular works are necessary. After that, all cracks and potholes are filled with a solution, i.e. Tamble.

- If necessary, the first layer of cement fill is performed, it will allow the floor to be maximized. Linoleum is not so big thick, so all irregularities and potholes will be immediately felt when walking, the canvas itself is quickly extended. Therefore, the fill is a necessary stage.

- If there is already a linoleum on the floor, then it is not worth removing it. First, it is better to examine the canvas. If there are no breaks, traces of mold, then it can be used as an excellent leveling substrate.

Article on the topic: How to hang blinds on plastic windows without drilling

Only after all preparatory work is over, and the cement base is dried, you can install a new coating using the selected method.

Concrete base substrate

For concrete floor, the linoleum is recommended to choose a special substrate that will not only make the base warmer, but also will prolong the service life of the material. Today, for this purpose, various types of substrates are used, which differ in the method of laying, costing, features of operation, characteristics. Among the most popular options should be noted:

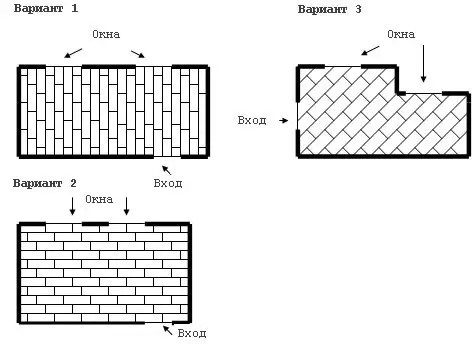

Laminate laying methods.

- Cork materials. Such substrates are made from a special cork crumb, the cloth is poorly tolerates strong loads. Furniture, household appliances, even sharp heels are detachment for this material, such a substrate will not last for a long time. But it will serve for excellent thermal insulation, noise insulation. Cork materials are recommended to be fitted in bedrooms, children's rooms, where they fully meet all operating requirements. The plug is produced most often in the form of large plates, which simply fit on the surface of the concrete floor, are attached to bilateral scotch.

- Substrates from natural jute are considered durable and durable, although their cost is quite high. They are not susceptible to rot, they are not afraid of moisture. Stay as simple as possible, can be used for any room.

- The substrates made of natural linen fibers are almost nothing to give up Joutow, but the cost of them is lower, which often advocates in favor of the material. They are laid quickly, their operational properties are high.

- Combined substrates from a mixture of materials such as wool, jute, flax, are impregnated with special antifungal drugs, antipirens. They are resistant to different types of loads and influences, and their cost is quite accessible. Can be used in any room, comes in rolls and plates. Used for thin linoleum when the floor must be insulated additionally.

- Foam substrates are distinguished by low price, but also the quality of them is not at the height. They wear out quickly, do not provide all the necessary properties. After a couple of years after use, the material is simplified, it is easy to break, requires replacement. It feels quickly, the roll is simply rolled over the surface, after which the joints are sampled by construction tape.

Article on the topic: How to choose an electrocos?

How to cut linoleum?

One of the responsible stages of premises preparation and gender to laying linoleum - the cutting of the canvas. If the room is small, then you can do the installation of only one whole piece. It is required to cut it in the form of the room.If the room is large, then you need to use 2-3 bands.

They are shown in such a way that the joints are as small as possible.

It is necessary to take into account not only the total area, but also the configuration of the room, the width of one strip. So it will be much easier to calculate the required amount of material, to reduce the percentage on the climb to a minimum. It is not so difficult to do this, it is necessary to pre-make measurements, after which the paper is drawing on a sheet of paper. It will help more accurately cut the linoleum. The material is cut with a sharp knife. Specialists recommend to use only special knives for working with linoleum for clean and even cut.

Laying with adhesive tape

Lining linoleum can be carried out using adhesive tape. It is used for large rooms, the area of which is from 20 m². This method almost completely displaced the full gluing of the coating to the base of the floor. In fact, it is important to observe accuracy of the linoleum. The adhesive tape allows you to smoke the joints between the individual canvas. It makes it easier to work, and makes it faster and better. A special double-sided adhesive tape is used to work. She squeaks not only the seams, but also ensures the fastening of the material to the floor.

Cold welding of linoleuma

Concrete floor arrangement scheme with waterproofing layers.

Most often, the method of cold welding is used for laying linoleum, i.e. Speeding seams with special adhesive compositions. This allows you to make seams almost imperceptible. A similar method is considered optimal for small premises, the area of which is up to 20 m².

The process of gluing a linoleum when laying on the concrete floor is as follows:

- First require the preparation of sex under linoleum. To this end, the old coating is removed, alignment is performed.

- The substrate layer is stacked on the floor. If a thin material is used, then the stage cannot be excluded.

- Linoleum jokes are samplesed using painting tape, while it is securely attached to the surface. After sizing, you need to cut the tape on the junction with a sharp knife, without damaging the linoleum itself. The needle of a tube with adhesive composition is introduced into the resulting incision, after which the mixture is neatly squeezed into the cut. The tube is smoothly moved along the entire length of the cut.

- Next, the edges are pressed so that two pieces of material can be welded. The glue literally dissolves the edges of the canvases, which, after frozen, form a monolithic coating.

- Glue when laying linoleum can be used different, the time of breathing is also very different. Therefore, it is necessary to focus on the manufacturer's recommendation. Scotch is cleaned over the amount of time that the instruction recommends, it is impossible to do before.

- For full welding, as a rule, almost a day leave. Then the adhesive tape is removed, the plinths are mounted to close the jacks between the floor coating and the wall.

Article on the topic: Balcony in Khrushchevka do it yourself: Step-by-step instructions

For laying linoleum, any floors can be used, including from concrete. But before starting work on laying outdoor coverage, it is necessary to perform a set of actions to prepare the foundation. For concrete floor, a simple work cycle is performed, most often needed alignment and installation of a special substrate, which extends the life of the linoleum itself.