Wooden floor deformation, which served many years, the problem of many of the owners of the cottages, private houses and apartments of the old sample. If it is completely disassembled and done again, for financial reasons, or you just want to simply change the type of floor covering, then the best way will be the alignment of the floor plywood without lag.

Why plywood will be the most suitable material for such works:

- It will carry the load perfectly;

- Weighs little and easily delivered to the place of work, which is for an individual master of a big plus;

- You can choose the required density and properties of the material;

- Types with moisture-resistant properties are not afraid of mold and fungus;

- low price;

- Fast and easy installation of construction;

- It is processed by grinding machine and is suitable for coating varnish;

- does not produce outsided odors;

- Natural environmental production;

- With proper laying serves a long time.

Preparation for work

Wooden floors begin to creak, and wear the boards and fasteners on which they are located, breeds irregularities. To update the wooden floor, you must first check the status of communications under it, and then get rid of the screen using several additional screws.If there are really spoiled areas that have been exposed to moisture or heavy loads for a long time, they should be replaced. Only after this can begin to align the wooden floor.

The room must be divided into square segments one meter, to determine the center of the room and measure with a laser level of deviation from the norm. There are three types of floor irregularities, for each of them they apply their own technology to solve the problem.

The first type is up to 2 mm, in this case the alignment of the floor plywood is practically not applied. This deficiency can be fixed with putty. It is prepared from a mixture of PVA and sawdust glue. Fight with the irregularities of specialized acrylic sealant. The appearance of the former sex will suffer from it, but because the reason for its update in the new final coating, be it linoleum or carpet.

Article on the topic: The angle of dawn of window slopes: installation sequence

The second type is from 2 mm to 5 mm per square meter. This is exactly the case when the correction of surface irregularities is necessary with the help of plywood sheets without using lag.

Third type - deviation over 5 mm. To solve the problem, plywood lags are used. There is already a complex type of construction, which increases the time of work.

Plywood sheets should be in heated room for two days before going to work. Where heating is currently impossible, the sheets need to be treated with warm water with a wet matter and give to stand on the edge of at least a day. Naturally, the work should not use the burst or crumbling sheets, otherwise the result obtained will only disappoint.

Choosing a plywood sheet

It is important to take into account that when aligning the wooden floor, it is necessary to choose the right thickness of the plywood sheet. It depends on the width of the boards on the floor. If the flooring is less than 20 cm, then a plywood is 5-10 mm thick. With the width of the boards, more than 20 cm or in cases where the floor is strongly deformed or was incorrectly laid with a pattern of a rings of a tree in one direction, then only a material of 18-20 mm width is used.

The width selection of plywood is closely related to what coating is prepared for facial use. If it is a linoleum or carpet, then the thickness of the sheets should not be big. These types of coatings with a smooth sheet surface look carefully and smoothly. If laying of laminate or parquet board is planned, then only the perfectly smooth floor can be suitable, which can only provide thick and solid sheets. The ideal option when the thickness of plywood and the final wooden coating coincides.

Plywood is made from wood fibers and veneer. Therefore, it will be better to walk the antiseptic before installing if moisture-resistant models are not selected for work. For repair, with your own hands in the private sector, it is recommended to use FSF or FC brands. The latter does not include phenols and more environmentally friendly.

Article on the topic: Procedure for troubleshooting in the work of plastic doors

The average thickness and moisture resistance to the couple with a comfortable price do not create barriers for a wallet and a qualitative result. FSF, on the contrary, is better suitable where there are often temperature differences and increased humidity. In its manufacture, phenol formaldehyde resins are used as adhesive. These elements are somewhat toxic, so such materials are used only for non-residential premises.

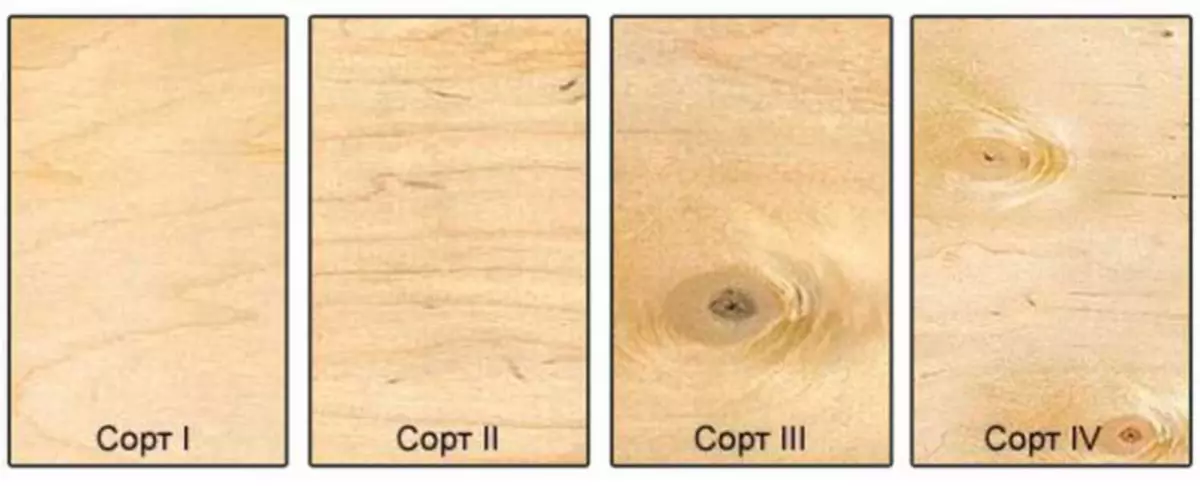

There are four grades of plywood

:

The first grade is the highest quality. There are no defects on its surface, but GOST allows cracks no more than 20 cm if the veneer has a tracking tracks.

Second grade. In this case, leakage of adhesive material is allowed, remnants, scratches and cracks can be taken to 5%.

Third grade. We will have to come to terms with dropped bitch and wormworms.

Fourth grade. Many flaws, but, nevertheless, the veneer gloves well and keeps in the whole design.

For sexual coating, with the subsequent laying of the final material, it is recommended to use the second grade. In cases with non-residential and technical premises, the varieties of worse are suitable. When plywood is used as a facial coating, it is better to use the first grade.

Installation of plywood sheets

Wide sheets are best divided into several rectangular parts, since the plywood is exposed to moisture and the warning can begin with time. When laying, it is impossible to forget that between the wall and the material you need to leave a couple of centimeters. The same rule acts when the sheets themselves are installed next to each other, only the distance decreases to 3-8 mm.

The technological clearance is needed, because when the operation of the sexual coating begins, the plywood will not pass on each other. In addition, it is necessary for elementary ventilation.

Shelves must occur both in a brick wall. Seam one row falls on the middle of the sheets in the following. This method helps to avoid problems with creak and gives the integrity design.

Article on the topic: Venetian: types and methods of application

The fastening of sheets should have to "comb" now the black floor. In these places there will be the greatest fit of the materials, which means that the fasteners do not have the gaps and will not be the cause of the breakdown of the site. At the same time, the places for fasteners are distributed evenly.

For self-screws, it is recommended to pre-make holes, since the spinning of the part can directly damage the already laid fane.

You need to drill holes in two stages:

- The first is the width of the diameter of the used screw;

- The second - with a large size of the hat, so that it does not drank out.

To score parts in Phaneur hammer is categorically contraindicated, as it can split it. The mounting to the wooden floor is usually done with the help of the corners. If the dowels are used, the two-stage hole is also drilled for them. On the perimeter of plywood dubel are located from the edge no closer than 2 centimeters.

How to apply lists

The plywood sheets with a roughness with one and polished on the other side (Marking "Sh1") When applied as the primary flooring, it is necessary to fasten the rough part to the top. It is necessary for sufficient clutch surfaces of the sheet and the last leveling layer. And the grinded side is needed when it is supposed to make the faeer facial sex. Then the screws are recessed in the plywood coils are masked by a sealant on an acrylic basis, and the surface of the grinded sheet itself is covered with a varnish one or more layers.

Markings "sh2" and "NSH", respectively, mean grinding from 2 sides and an unlightened sheet. Those models where plywood is polished, have a prescription in the form of a free formaldehyde level. For residential premises, the best solution will be "E1" - less than 10 mg of formaldehyde per hundred grams of plywood.

With all these tips, the alignment of the floor plywood will not be a problem for non-professional. Repair done with your own hands brings satisfaction and tremendous experience.