Enye yezindlela ezinokwethenjelwa kakhulu zokuxhuma izintambo - ukuthengisa. Le nqubo lapho isikhala phakathi kwabaqhubi ababili sigcwele solder esincibilikisiwe. Ngasikhathi sinye, iphuzu lokuncibilika lomthengisi kufanele libe ngaphansi kwendawo yokuncibilika yezinsimbi ezincibilikisiwe. Ekhaya, i-iron ye-soldering isetshenziswa kaningi - idivaysi encane esebenza kusuka ngogesi. Ngokusebenza okujwayelekile, amandla e-soldering iron kumele okungenani ibe ngu-80-100 W.

Okudingayo ngokuthengisa insimbi yokuthengisa

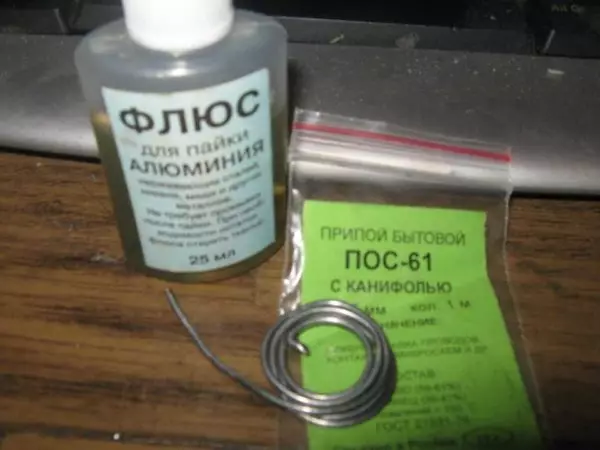

Ngaphezu kwensimbi yokuzinzela, udinga amasosha, i-rosin noma ama-fluxes, kuyinto efiselekayo ukuba nokuma. Enqubweni yokusebenza, kungadingeka ifayela elincane nama-pastas amancane.

Imvamisa kufanele kudingeke izintambo zethusi, ngokwesibonelo, kuma-headphone, lapho kulungiswa izinto zasendlini, njll.

Rosin kanye fluxes

Ukuthola ukuxhumana okuhle kwezintambo, kuyadingeka ukuzihlanza ekungcoleni, kufaka phakathi ifilimu ye-oxide. Uma imithambo ye-mono isengahlanzwa ngesandla, khona-ke abaqhubi abahlanzekile ngeke bakwazi ukuhlanza ngokujwayelekile. Zivame ukuphathwa nge-rosin noma i-flux - izinto ezisebenzayo ezincibilikisa ukungcola, kufaka phakathi ifilimu ye-oxide.

Futhi i-rosin kanye ne-fluxes isebenza kahle, kuphela ama-fluxes okuwusebenzisa kube lula - ungamfaka ibhulashi kwikhambi bese ucubungula ngokushesha izintambo. Ku-rosin kuyadingeka ukubeka umqhubi wesifundo, bese usishisa ngensimbi elungiselelwe ukuze into ebilisiwe iliphoxe yonke yensimbi. Ukuntuleka kokusebenzisa i-fluxes - uma behlala ezingqwabeni (futhi bahlala), kancane kancane banenkani yegobolondo eliseduze. Ukuthi lokhu akwenzeki, zonke izindawo zokuthengisa kufanele zicutshungulwe - geza izinsalela zotshwala.

Amasosha nama-fluxes e-soldering soldering Iron Copper izintambo

I-Rosin ibhekwa njengendlela yendawo yonke, futhi ama-fluxes angakhethwa ngokuya ngensimbi ezosonda. Endabeni yezintambo kuyinkosa noma i-aluminium. Okwe-Copper no-aluminium izintambo zithatha i-flux LTI-120 noma Buru. Umkhuhlane owenziwe ekhaya ovela ku-rosin futhi utshwala obuphikisayo (1 kuya ku-5) usebenza kahle kakhulu, futhi umane ukwenze ngezandla zabo. Ngotshwala angeze i-rosin (uthuli olungcono noma izingcezu ezincane kakhulu zalo) bese unyakazisa ukuncibilikisa. Lapho-ke ukwakheka ungakwazi ukucubungula abaqhubi kanye nama-Twists ngaphambi kokupholisa.

Isihloko ngesihloko: Ukulungiswa kwama-headphones

Amasosha athengisa ngentambo ye-soldering Iron Copper asetshenziswa ngama-60, i-PIAC 50 noma i-POS 40 - I-Tin-Lead. Nge-aluminium, izingoma ezisuselwa ku-zinc zifaneleke kakhulu. I-CO-12 ne-P250A (kusuka ku-P250A (kusuka kuTin ne-Zinc), Brand A (Zinc kanye ne-Tin ngokungezwa kweCopper), umhlangano ophakathi nendawo (i-zinc nge-aluminium).

Kuyinto elula ukusebenzisa isosha nge-rosin

Kuyinto elula kakhulu ukusebenzisa amasosha, okubandakanya i-Rosin (PM 61). Kulokhu, kuyanyamalala isidingo sokucubungula kuqala umqhubi ngamunye ngoRosin ngokwahlukana. Kepha ngokuthengisa okuseqophelweni eliphezulu, i-iron elungiselelwe kufanele ibe neyodwa - 80-100 w, okungashisa ngokushesha kuze kube yilapho kudingeka amazinga okushisa adingekayo ukuze uthengise.

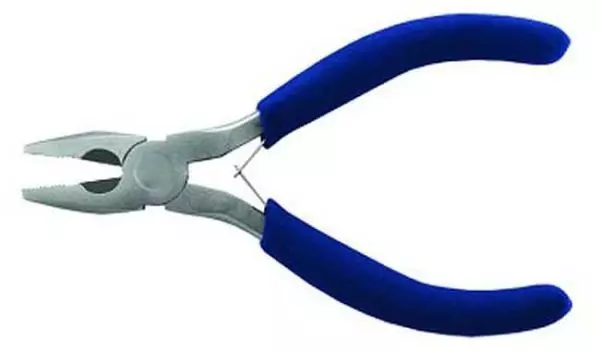

Izinto zokusiza

Ukuze uxazulule i-wire yensimbi ye-soldering, edingeka kakhulu:

- Yima. Kungenzeka kube ngensimbi ngokugcwele noma nge-mest yokhuni / yepulasitiki, abaphethe insimbi yensimbi ye-soldering. Kuhle futhi uma kunebhokisi lensimbi elincane le-rosin.

Ukuthengisa i-iron yensimbi elula ngokwengeziwe nge-Stand Homemade nefekthri - akubalulekile kakhulu

- Ifayela. Ngaphambi komsebenzi, insimbi yokudalula icijile. Kumele kube bushelelezi futhi ihlanzekile ngaphandle kweminonjana ye-nagar. Bese ugoqa kalula.

Ngakho-ke udinga ukucija i-ngiyaxolisa insimbi yokuthengisa

- I-passastatia. Bamba izintambo ngeminwe yakho ngesikhathi sokuthengisa kunzima - ithusi ne-aluminium zinokuphakelayo okuphezulu okushisayo, okuholela ekufuneni okusheshayo kwezindawo eziseduze. Ngakho-ke, ukuthengisa insimbi yensimbi elungiselelwe kungcono kakhulu uma ebabamba. Ithuluzi kuphela okufanele libe ne-mineiature, ngezibambo ezincanyana nezipanji. Ngokuyinhloko, kungenzeka ukusebenzisa ama-tweezers, kepha ngaphezulu kwayo (lapho kubanjwa khona ngeminwe yakho) Kuyinto efiselekayo ukubeka ishubhu elishelele ukushisa - Insimbi nayo iyafudumala ngokushesha.

I-Passatia - ukubamba izintambo

Ngokuhlanza i-Flux, kungadingeka utshwala, ngoba ukufakwa - itheyiphu kagesi noma amashubhu ancipha amashubhu ahlukahlukene. Yilokho kuphela izinto zokwakha namathuluzi, ngaphandle kwawo ucingo lwensimbi ye-soldering olungenakwenzeka.

Inqubo yokuthengisa imbiza kagesi

Zonke izintambo ze-soldering Technology Soldering zingahlukaniswa ngezinyathelo ezimbalwa ezilandelanayo. Bonke baphindwa ngokulandelana okuthile:

- Ukulungiselela abaqhubi. Lapho izintambo zokuthengisa, zikhululwa ngokwahlukana. Ngemuva kwalokho ifilimu ye-oxide isuswa kubo ukuthi isuswe ngomshini. Ungasebenzisa ucezu oluncane lwephepha le-emery ngama-okusanhlamvu amancane. Insimbi kufanele ihehe futhi ibe lula.

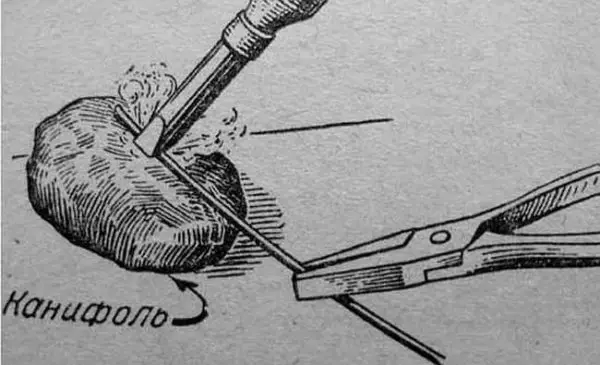

- Tinning. Shisisa i-iron ye-soldering endaweni yokuncibilika ye-rosin (uma ithinte iqala ukuncibilika). Thatha umqhubi wesifundo, ulethe ucezu lwe-rosin, ufudumele insimbi yokuthengisa ukuze yonke ingxenye enamandla yocingo icwiliswe eRosin. Lapho-ke ekudonsweni kwensimbi ethengisa i-soldering thatha ithonsi le-solder futhi ulisakaze ngengxenye yelethwe ngumqhubi. I-solerder isakazeka ngokushesha, ukumboza ucingo oluncane lwesendlalelo. Ukuze isatshalaliswe ngokushesha nangokulinganayo, ucingo luphenduka kancane. Ngemuva kokuhlwitha, abaqhubisi bethusi balahlekelwa ubomvu, baba yisiliva. Ngakho-ke phatha zonke izintambo ezidinga ukuthengiselwa

I-Addoutitute desidue

- Abaqhubi abanohlu basongelwa ndawonye, bazilungise ngeminwe yabo - ukuze bazizwe beqinile bodwa. Uma ukuSoldering kufanele kube ubude obukhulu, ungenza ukusonteka. Ukubamba abaqhubi, ebhuleni bathatha umthengisi, bayicindezele endaweni ye-beldering, esebenzisa umzamo othile. Ngasikhathi sinye, indawo yokuthengisa ifudumele, iqala ukubilisa i-rosin, umthengisi usakazeka. Lapho emboza yonke indawo, accounting phakathi kwabaqhubi, kungabhekwa ukuthi insimbi yokuzinzela abaqhubi isiphothuliwe. Basabanjwa benyuka isikhathi esithile - ngenkathi umthengisi engapholi phansi (ukusheshisa inqubo kule ndawo).

Lapha, empeleni, konke. Ngendlela efanayo, izintambo ezimbili noma ngaphezulu zingathengiswa, ucingo lungathengiswa ngohlobo oluthile lwe-pad yokuxhumana (ngokwesibonelo, lapho kuthengiswa ama-headphones - ucingo ku-plug (ucingo lungathengiswa kwi-pulazi noma kwisayithi ekhanda), njll .

Ngemuva kokuqeda ukuthengisa i-wire wire we-soldering futhi bapholile, ukuxhumana kumele kuhlukaniswe. Ungafaka i-uhlukanise, ungagqoka, bese ufudumeza ukushisa kweshubhu lokushisa. Uma sikhuluma nge-wiring, uvame ukweluleka kuqala ukujika okuningana kwetheyipu, futhi ngaphezulu ukugqoka ukushisa kwe-shrink tube okufudumele.

Ukwehluka kobuchwepheshe lapho usebenzisa i-flux

Uma kusetshenziswa i-flux esebenzayo, hhayi i-rosin, inqubo ye-meturn yenqubo. Umshayeli ohlanziwe ugcotshwe nokwakheka, ngemuva kwalokho afudumeza insimbi yokuthengisa ngenani elincane lomthengisi. Ngaphezu kwalokho, konke kuchaziwe.

Skinger nge-flux - ngokushesha futhi kulula

Kunokwehluka futhi lapho kusonta okusonta nge-flux. Kulokhu, awukwazi ukusonta ucingo ngalunye, kepha usonteke, bese ucubungula i-flux bese uqala ngokushesha ukuthengisa. Abaqhubi abakwazi ngisho nokuhlanzwa - izingoma ezisebenzayo zinika amandla i-Oxide Film. Kepha esikhundleni salokho, indawo yokudalula kuzofanela isule - ukugeza izinsalela zezinto ezinolaka ngamakhemikhali.

Izici zokuthengisa izintambo ezihlanjululwe

Ubuchwepheshe be-soldering obuchazwe ngenhla bufanelekile. Uma ucingo lukhubazekile, kukhona ama-nuances: i-wiring iphakanyiswa ngaphambi kwemithwalo, ngakho-ke ungathuthukisa yonke into eRosin. Lapho usebenzisa i-soler, kuyadingeka ukuqinisekisa ukuthi ukuthunyelwa ngakunye kwambozwa ungqimba oluncane lwalowo mthengisi. Ngemuva kokupholisa, izintambo zisontekile futhi zingene kuhhafu owodwa, khona-ke ungathengisa insimbi yokuthengisa njengoba kuchaziwe ngenhla - ukucwilisa ukugwazwa ku-aleike, kufudumale indawo ye-spike futhi usebenzise i-tin.

Lapho ubhala izintambo ezihlabekile kudingeka "fluff"

Kungenzeka yini ukuthengisa ucingo lwethusi nge-aluminium

Ukuxhumeka kwe-aluminium nezinye izinsimbi ezingamakhemikhali azikwazi ukwenziwa ngokuqondile. Njengoba ithusi lisebenza ngamakhemikhali, khona-ke ithusi ne-aluminium alixhunyiwe futhi alithengisi. Ikeke ekuvuselweni okuhlukile kakhulu okushisayo nemijikelezo ehlukile. Lapho kudlula amanje, i-aluminium ishisa ngokwengeziwe futhi ngaphezulu iyanda. I-Copper ifudumele futhi yandisa kakhulu. Ukunwetshwa okungapheli / ukuncipha kwamazinga ahlukahlukene kuholela eqinisweni lokuthi ngisho noxhumana naye omuhle kakhulu uphukile, kwakhiwa ifilimu le-toxcoducting, konke kuyeka ukusebenza. Ngoba ithusi ne-aluminium musa solder.

Uma kunesidingo esinjalo kuvela ukuxhuma abaqhubi bethu be-Aluminium, yenza uxhumano olubunjiwe. Thatha i-bolt nge-nati efanelekile kanye nama-washer amathathu. Emaphethelweni e-Concerable Hires Fomu amasongo ngosayizi we-bolt. Thatha i-bolt, faka i-puck eyodwa, khona-ke umqhubi wesifundo, enye i-puck - umqhubi olandelayo, ngaphezulu - i-washer yesithathu futhi yonke into ilungisa inadi.

Abaqhubi be-Aluminium neCopper abakwazi ukulder

Kunezindlela eziningi zokuhlanganisa i-aluminium ne-zethusi, kepha ukuSoldering akusebenzi kubo. Ungafunda ngezinye izindlela lapha, kepha i-bolt iyilula futhi ithembekile.

Isihloko ngesihloko: I-Plinth evumelana nezimo: Ungagoba kanjani ubulili, izeluleko zochwepheshe