Any door carries not only utilitarian load, but also performs a decorative function. The panel door successfully combines both of these elements, being both reliable, and an attractive element of the design.

The panel door combines the elements not only the decor, but also the reliability of the structural elements.

Varieties of violent doors

Since the pilient doors are very reliable, excellently provide noise insulation and perfectly complement the decor of the room, they use unchanged popularity, especially as interior doors. A distinctive feature of a panel door is necessarily the presence of a rather massive frame, as well as inserts that are called sealers. Pilenki can be performed from various materials:

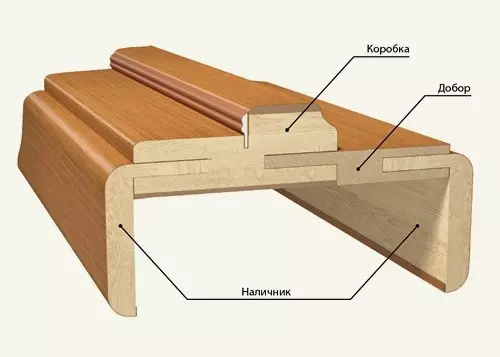

Scheme of the Stylechate Door Scheme.

- One of the most beautiful options is glass inserts that can be made using transparent or matte glass, but the stained glass window looks especially attractive;

- Plywood or chipboard is often used as panels, this is a rather lightweight and budget version of the fillets;

- For the manufacture of inserts, an array of wood can be used, which makes the door more expensive, but at the same time and more durable.

Pilenks are attached both with the help of a groove-spike system and using a special stroke, which makes it easy to replace inserts if necessary.

Advantages of their independently made panel door

Having decided to install the panel door indoors, it is not necessary to use it purchased. If there are small skills and desires, such a door can be made independently. If you make doors with your own hands, then at the price they will work much cheaper than a similar option selling in the store.

The process of assembling the panel door.

Self-made scribble doors will get rid of the need to adjust them in size of the doorway, since they are originally manufactured by certain standards.

Due to the peculiarities of the manufacture of independent doors, the doors are less subjected to destruction due to the effects of temperature difference and humidity. Among other things, you can independently make exclusive doors on more than a deocratic price.

Preparatory stage of the manufacturer of the panel door

For the manufacture of a panel door with their own hands, in addition to the desire and certain skills of working with wood, it will take a relatively small set of tools:

- Roulette and pencil;

- wood hacksaw;

- sandpaper with large and small grain;

- chisel;

- screwdriver.

Article on the topic: Orthopedic mats for children do it yourself

As the materials necessary for the manufacture of the door, you need to stock:

Tools for mounting the panel door.

- To create a box, you need thick boards, the width of which should be up to fifty millimeters, you can use a special bar, you need three pieces: two - for the manufacture of the vertical part and one - for the top transverse part;

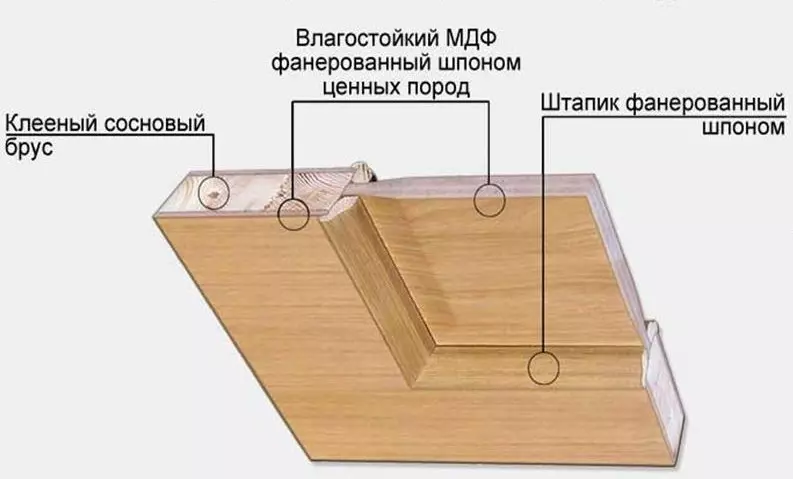

- To create a frame, we need pretty strong bars and rails, reliability depends on their strength;

- For the manufacture of fillets, you need to buy chipboard, faeer or glass;

- In some cases, it is necessary to purchase a stroke for fixing the fillets, in particular, it is necessary if the panels are made of glass;

- For fastening, glue and screws are needed;

- need to stock fittings (door hinges, handles, locks);

- Do not forget about finishing materials (paint, varnish, various specialized coatings), which are selected depending on the operating conditions and design concept.

Having decided to make a pale door with their own hands, initially need to decide on the materials from which it will be performed.

For the manufacture of the door frame and frame, it is better to choose solid wood species that are quite resistant to temperature and humidity drops. It is the correct selected material that will help make the door resistant to various external influences and reliable. As a rule, the choice is better to stop on solid rocks of wood, for example on oak or ash.

Scheme assembly box of the panel door.

Pine is the most inexpensive and affordable breed, which is resistant to temperature and humidity drops, because it is often selected as a material for the manufacture of the door. To optimally select specific wood, you can consult with a consultant in the store.

For the manufacture of panels, you can use the Fane or Chipboard, they allow you to make the design of light and inexpensive. If you wish, you can buy a more expensive array of wood, it will make the door stronger and solid. Often, inserts from glass are used for interior particle doors. Glass can be transparent, matte, corrugated or patterned. Very beautiful looks with stained inserts.

The real stained glass window is quite expensive, so sometimes the painting of glass is used, as a rule, two-way to create a full effect of stained glass.

Manufacture of a panel door

The initial stage of the installation installation is the manufacture and installation of the doorway, or the door frame. In order for the door to look attractively and did not spoil the design of the room, it is important correctly and smoothly make the door frame. It should be without overwhelming and width differences.

Article on the topic: Connecting PE Explorer to outlets

After installing the door frame, you can proceed to make the Pilencate door itself with your own hands.

Initially, it is necessary to draw a few sketches of the future panel door on paper, taking into account personal preferences and common sense in terms of the complexity of execution. The panel door can be quite complicated in performance, because novice masters are best started with the manufacture of six-natal doors. The selected sketch is detailed, all sizes are locked on it. Stripping from the selected sketch, the necessary materials for the manufacture of the door are purchased.

Device of the panel door.

In order to make the door with their own hands, the frame is primarily done - the basis of the structure, which is responsible for its strength and on which the fillets are fixed. The more reliably, the frame is made, the more reliable the panel door itself will be.

With roulette, the size of the doorway is measured. To design the door, it is necessary to consider that it ultimately should be on four to six millimeters less than the door frame width that must be left for normal fit. In accordance with the resulting dimensions from a bar purchased for the manufacture of a frame, the basis for the future door is made. To do this, on a bar that should be smooth and without mechanical damage, with the help of a pencil, the required length is noted. Then, with the help of a tree with a tree, an excess part is scorn. If possible, you can cut the bars on the desired size in the store to make it easier and speed up the process of manufacturing the door. Such sawing will be better, since the use of modern equipment allows you to get the optimal result. Thus, two side main racks are obtained, two crossbars, which are fixed from below and on top of the structure, as well as internal crossbars and rails that serve as jumpers.

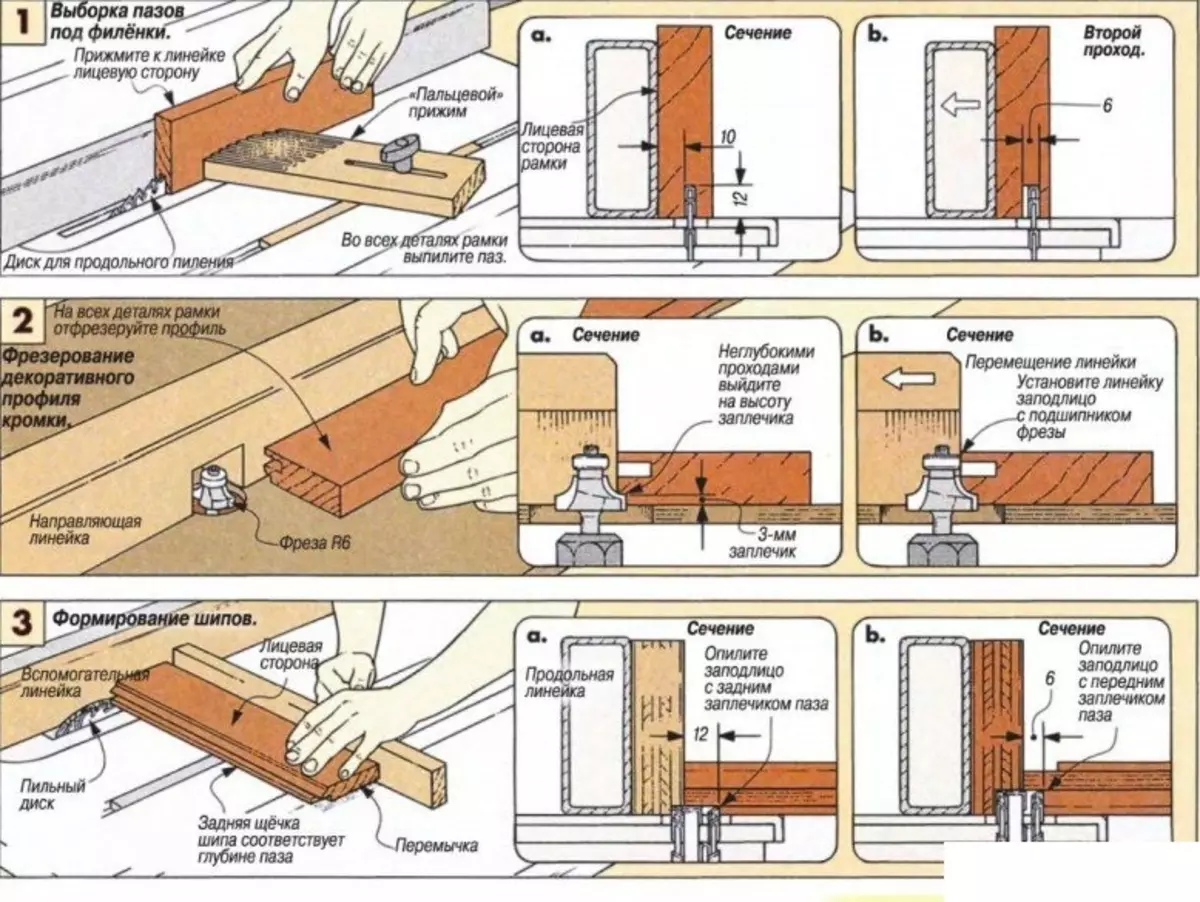

For dense fastening parts with each other, grooves and spikes are made in the right places that must be perfectly approached by size. For additional attachment, the parts are labeled with a special joinery glue, which connects them more tight. In places of attachment of future fillets, special chamdes are made.

Article on the topic: How to choose the right Tulle to the curtains in the room: experts advise

Mounting the panel door.

After making the frame of the future door, you can start making fillets. If for fillets that will be inserted into the door, wood is used, it is better to use an array of boards to avoid the need to create a chamfer. From the array of chamfer, which will decorate the door, the ready-made piece is cut, there are special sleeves in its edges, which allow Pilenka to securely entrenched with the chamfer.

If the manufacture of fillets from a solid piece of wood array is impossible, but there is a desire to use precisely wood, then the fillets are made of pieces of wood, which are bonded with each other using the spikes and grooves system, additionally leaving the joinery glue to give greater strength. After the sealer, assembled from the parts of the wood, is ready, in its edges, the spins are made for fastening with the chamfer.

Filewood made from wood can be additionally decorated with special tools processing, but for this you need to have certain skills.

If the fillets are made from chipboard or plywood, they are cut from the selected material in accordance with the required dimensions.

Glass inserts are also trimmed under the case of the door size or initially in the manufacture of jumpers and the rails proceed from the existing size of glass inserts.

If a glass with a painting, imitating stained glass windows, will be used as insertion, then it should be done in advance before fixing the door.

Glass fillets are fixed using a stroke, which makes it possible to simply simply change the glass if necessary.

After the door is made, processed and covered with paint or varnish, all the necessary fittings are attached to it. After that, the door is installed in the opening.