One of the important issues in the construction of the house is the flooring. Modern tendencies in the interior design return us to the use of natural materials. The tree is the most environmentally friendly and practical of them. Such a coating adds not only comfort and aesthetics. It is durable, possesses high strength, well keeps warm.

This floor is ideal for both cottages and country houses and an urban apartment. Update paint or lacquer coating every 4-5 years. The tree will serve you not one dozen. However, it is necessary to seriously approach the issue of preparing the basis for its laying. Among the many ways, styling on lags is most proven.

What are lags for what

Floor lags are floors of wood, metal, plastic or reinforced concrete. As a rule, they have the shape of beams that are stacked across the future of the final coating. This is a kind of lamp serving the base of the floor.

Most often they are made of wood in the form of bars of certain parameters. It is more affordable, cheaper and is not inferior in quality to other materials. The method of such styling is used to reliably fasten the floor to avoid deflection under heavy furniture so that it does not vibrate and did not creak. According to statistics, it is used in 90% of cases.

The main advantages of the lag:

- absorption of noise;

- Floor ventilation;

- an increase in thermal conductivity;

- the ability to use empty space for various engineering communications;

- uniform load on the base;

- floor alignment;

- an increase in the strength of the coating to several tons per square meter;

- simplicity of installation and replacement;

- low cost.

The material for lag is most often served by pine, spruce or fir. Larch is more expensive, so it is not so popular. Since they serve as a base for a germ, then grades 2 or 3. They may not be so neat as 1 grade. The presence of bitch and leaks of the resin will not affect the reliability of the structure.

As a rule, the tree is stored under certain conditions. The humidity of the finished material should be about 15-20%, but not more. Before starting work, wood is subjected to mandatory treatment with special impregnations.

They are harmless to human health and often require simple dilution with water in certain proportions. This prevents the appearance of fungus and mold on the tree, protects against bugs and rodents. The procedure is quite simple, but re-applying is required after 3 or 5 hours.

Article on the topic: How to choose the right sofa to the interior?

How to put lags: Determine the size

Floor lags perform a lot of useful features. It should be borne in mind that improper installation in the future can turn into sad consequences. The form of the bar must necessarily be rectangular.

Best of all, they maintain a large load with such a relation when the height is more than one-day width or twice. The bar is always put on the edge only. The table shows the size of the Lag section for certain spans. The step between them in this case is 70 cm:

The size of the cross section depends on the strength of the material used and the intended load on the floor. For residential premises, it is found that it does not exceed 300 kg per m2. These values are recognized by experts. However, they can be thicker depending on the situation. For example, it is necessary to increase the space for a thick insulation. Or an increased load on the coating is supposed. The stronger the material, the less it may be its size. This applies, for example, to the gland.

The lag length must correspond to the length (width) of the room minus 2.5-3 cm. This stock is necessary to preserve the strength of the structure in the event of temperature and humidity fluctuations. It is recommended to use long lags. Well, if their size corresponds to the length of the room.

If you need to dock them, the connection places should be shifted relative to neighboring after about half the meter, and better on the meter. In the site of splicing make support. Usually it is performed in the form of a column. Splicing occurs with the help of galvanized linings, but more often - in trustees.

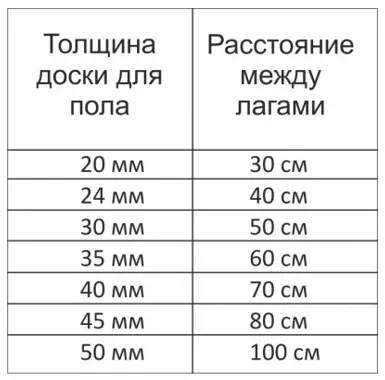

Be sure to take into account the distance between the floor lags. Professionals call it "step". It is determined depending on the parameters of the genital boards. The thicker coating the floor, the more there may be a step. Accordingly, the thinner, the less we take a step.

From the table you can withdraw regularity. If the thickness of the board increases by 0.5 cm, then the step increases by 10 cm. For a stronger coating (for example, plywood and OSB) calculations may be different.

Since these materials are more persistent to deflection, the step increases. With a thickness of 18 mm, the pitch will be up to 40 cm. At 25 mm it will be up to 60 cm. Each sheet is fastened to three different lags. Must be attached to the center and the edges, going on half of the lags.

How to fix lags to the base

Lags are placed on a tree, soil and concrete. First you need to know which tools are required for this. So, in addition to the BRUSEV themselves, it is necessary to have a level, an electrolybiz or a manual saw. We store screws, screws, anchors and nails. We definitely have a perforator with yourself (when laying on concrete), rule, ax, screwdriver or drill, hammer and nail-holder.

Article on the topic: Curtains for the hall with a balcony (photo)

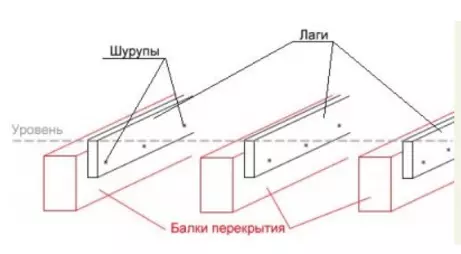

In the case of fastening the lag to wooden floors, it is necessary to secure them to the side sides of the beams. This is done on the basis of the fact that beams are usually not installed in terms of level. In addition, this method helps not to overestimate the floor, saving precious centimeters in rooms with low ceilings.

If the height allows, then, as an option, the bar is laid on top across the beams. Fix them with screws by 6 mm, pre-drumped the hole 2.5 mm less than the diameter. This will prevent wood bundle. The length of the screw must be 2.5 times longer than the width of the lag.

Placeing lags on the ground, it is necessary to clean and catch it in advance. Next are measured to install poles. They will serve as a support. The distance from the wall to the first lags should be from three to twenty centimeters. At the outlined distance, pits of a 10 cm depth of 10 cm are digging, falling asleep and poured with water for greater strength. It will be a foundation for pillars.

It is recommended to make its size of at least 40 per 40 cm. Then the polyethylene is placed on top of the top to it, a column of two or three bricks fixed by cement is erected. Then they are covered with rubberoid, the timber is stacked on top. Lugi is fixed with galvanized corners to the walls or to the crown of a church.

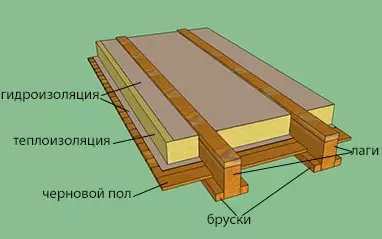

Lags often fit on the concrete base. Waterproofing in this case is extremely necessary, otherwise the floor will constantly be cooked. It is quite suitable for the usual polyethylene film. However, experts are increasingly beginning to use pholoisol - this foamed polyethylene with a foil layer, which is placed in the direction of the dwelling, reducing heat loss.

The bar is attached to concrete with anchors. The insulation is a stel between lags, but not for them. Concrete screed, as a rule, eliminates problems with alignment of lag before laying floorboards.

General recommendations

Make sure the tree is dried and processed by an antiseptic or bitumen. This will significantly extend the life of the structure. With a humidity of more than 20%, the tree can hub, disrupting the integrity of the structure. The boards brought from the warehouse should lie at room temperature for several days. This is especially true for winter time. It is not recommended to raise the floor with air humidity less than 60%.

Article on the topic: Knitted curtains crochet - beautiful and easy!

Do not cut and plan the boards in the room where the floor is mounted. Sawdust can cause rotting.

Do not forget to use waterproofing. For noise insulation, as a rule, use DVP, rubber, foamed polyethylene, slag or sand. Heat in the house will continue longer if you fill the emptiness under the floor of mineral wool, clamzite, expanded foam or isospan.

Use the rule after laying. Put it across the beams, remove the lumens, aligning the height. It is easy to do with special modern adjustable fasteners that appeared in the construction market. Paul Stelite only after all level alignment procedures.

The shorter step, the longer the floor will last. However, the main indicator of durability is the coating and base material. The most durable is the larch wood.

The beam installation is usually carried out by the window, i.e. across the room. Paul boards are then placed along the room, i.e. From the window. However, this is just a recommendation and taste case.

Paul Steel from the angle, placing boards perpendicular to lagas. The distance from the walls should be about 1 cm. It is left in case of the deformation of the tree depending on the temperature and humidity of the environment. This distance closes the plinth. In case the boards lie close to the wall, the floor can swear.

The board is attached to each beam. The holes for the screws should be drilled in advance to avoid bundle.

The most common embodiment between lags is from 50 to 56 cm. As a rule, it does not exceed a distance of 69 cm.

Disassemble the lags and the wooden floor is simple enough. It is necessary to endure all the furniture from the room, remove the plinth, open the boards or sheets of chipboard. After checking, old boards are replaced with new ones. The lags themselves can be replaced partially. Just cuts out a piece of rotting wood and a new one is admired.

Do not forget to use protective impregnation for new boards. Check the ends of the beams for the presence of rot, insulate the base isolation if it is. Repair of the floor can be a reason to insulate the dwelling.

Lags deservedly are the easiest and most popular way to create a reliable basis of our sex. If desired, everyone can take on this interesting thing and step By step to achieve the goal. The most pleasant reward for works will be the warmth and cozy atmosphere for many years.