The staircase is an actual element in the construction of private houses. It provides a comfortable rise to the upper floor, can be a direct or rotary, curvilinear or screw. For the house, erected from the tree, the wooden staircase is perfectly suitable, however, for brick or block buildings, the option made of concrete. Make a formwork and pour a concrete product without the help of specialists is not as difficult as it may seem, especially by reading this article.

Features

Any staircase must have a high degree of reliability and safety. By calculating the owners of the house, such a design is built on the century. But, in addition to the strength, the aesthetics of the structure plays a major role. All listed criteria have monolithic concrete staircases. These are durable, resistant to any impacts of the structure, which in all respects exceed wooden and metal counterparts.

There are also many ideas on the design design of concrete ladders, which will make it possible to embody any fantasies and requests.

Advantages and disadvantages

If you have not yet decided, it is worth installing a monolithic staircase or not, we recommend analyzing all its advantages and disadvantages, and already draw conclusions. Special attention should be paid to such indicators such as cost, design versions and operational characteristics.

Specialists celebrate such advantages of concrete structures:

- Universality. The concrete staircase can be installed both inside the house and on the street. The degree of air humidity does not affect its functionality. When complying with the correct fill technology, it will serve several decades.

- High degree of strength. Concrete does not compare with any other materials. He has excellent resistance to dynamic loads. The staircase will not be covered with time. It will delight and lack of a screap when moving along it.

- High fire fighting performance. In case of emergency situations, such stairs serve through evacuation. Therefore, resistance to fire is indisputable dignity.

- A variety of forms and finishes. Only concrete fill will allow to give the most intricate and original form. It is possible to perform any finish option: wood, MDF, laminate, ceramic tile, stone, glass, etc.

Along with all the presented pluses, there are some features of durable concrete products that can exclude the possibility of their construction:

- Huge weight. For the design of this type, it is necessary to have a reliable base and overlap. Otherwise, it should not be taken for the device such a staircase.

- Large labor costs. The construction of any concrete monolith is a multi-step process that requires physical effort and patience.

- Mounting complexity. When working with reinforcement and concrete mixture, it will be difficult to cope with the concrete one, so it is better to invite a couple of assistants.

- Long term of commissioning. Concrete after the fill must stand at least four weeks. Immediately use the staircase.

Many believe that concrete products have a rough look. Such reproes are groundless, as a good finish will turn the design into a work of art.

Payment

You do not need to hope that the concrete staircase can be built "on the eyes." Any inaccuracy will significantly reduce all the advantages of the design and make it unsafe. It is necessary to take the rule that any construction should be carried out in accordance with generally accepted standards and subject to technologies. Proper settlement processes play one of the most important roles.Main settings

To begin with, the design site is defined. The area allocated for the climbing device to the upper floor will affect its size. Even at the stage of creating a project of the house, special attention should be paid to the selection of staircase.

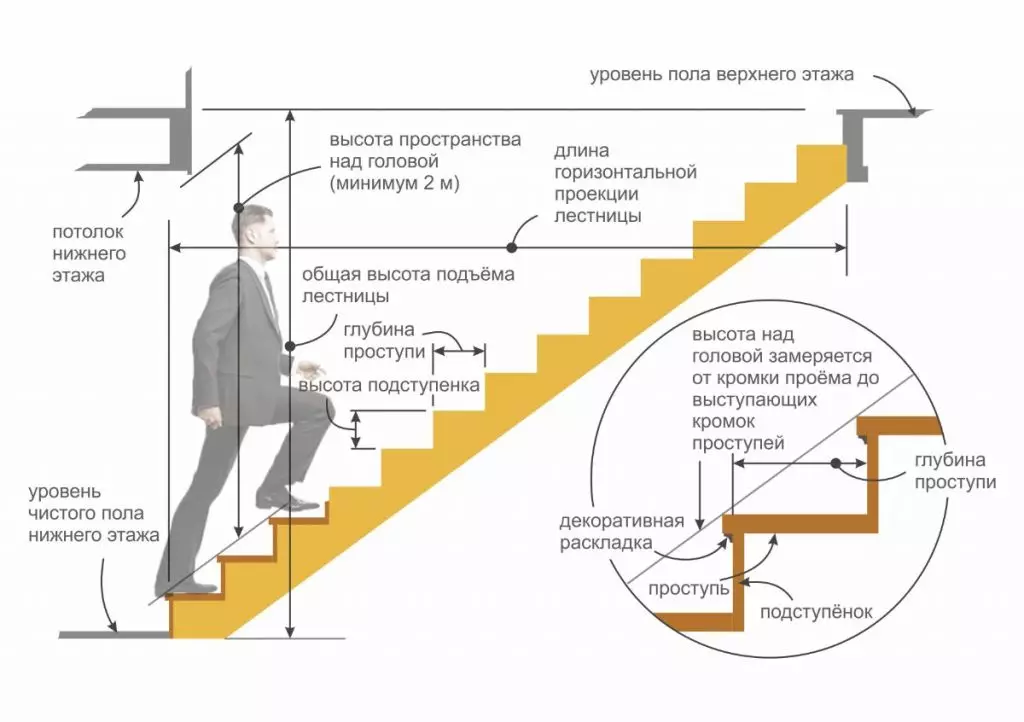

These parameters are taken into account:

- The height of the stairs;

- design projection on the floor;

- Width of the Owl;

- Stage depth;

- The height of the riser.

Be sure to calculate the parameters of the passage over the staircase. The distance from any stage to the upper overlap should not be less than human growth.

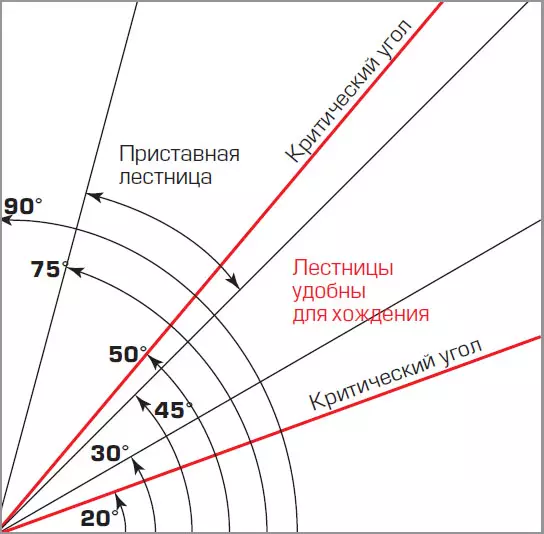

Steep

For the device of the ladder in living conditions, the angle of inclination must be comfortable. Considate the fact that young children will use it, and the elderly. The steepness of the devices for convenient movement varies within 30-45 degrees. The last parameter is critical. The optimal angle of inclination for stairs in a private house is 40 degrees.

Length of a staircase

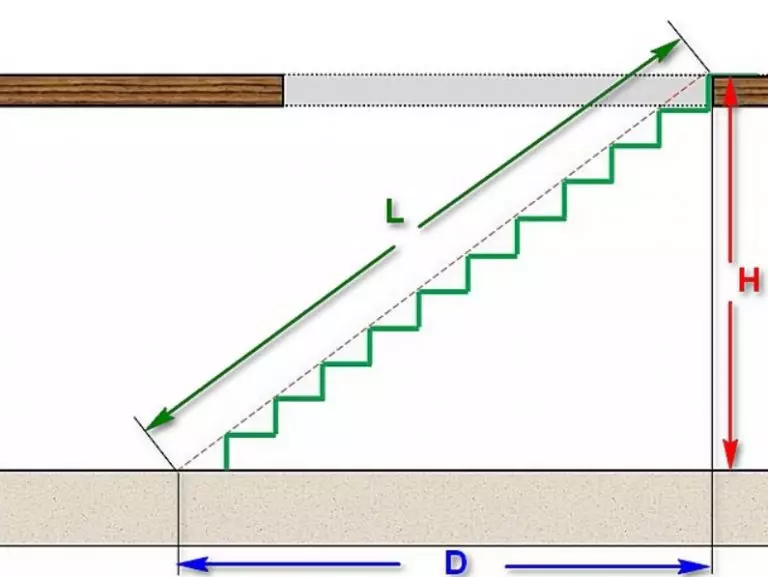

The length of the staircase determines the area allotted for its device. It is calculated using the geometric formula - the Pythagoreo theorem. To do this, you need to measure such parameters as the distance from the floor to the overlap to the second floor and the projection length of the proposed design. These two values are considered to be rectangular triangle customs, the length of the staircase is hypotenuse. To calculate, it is necessary to fold the squares of the obtained numbers, and then remove the square root.

Article on the topic: Main options for lighting stairs in the house and selection criteria (+58 photos)

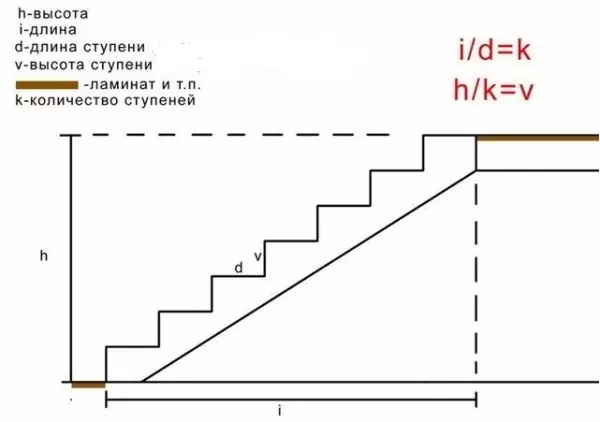

Calculation of the number of steps

Speed parameters also pay special attention. To begin with, determine the number of alleged steps. In this case, the projection of the concrete product on the floor is divided into the width of the sticky and receive the number of steps. As practice shows, the result is not an integer. Next, adjust - extra centimeters are added to the first or last step.

Convenient movement for a man in a concrete staircase is when they start and finish up with the same leg. Therefore, the number of steps is better to do odd.

Width and height

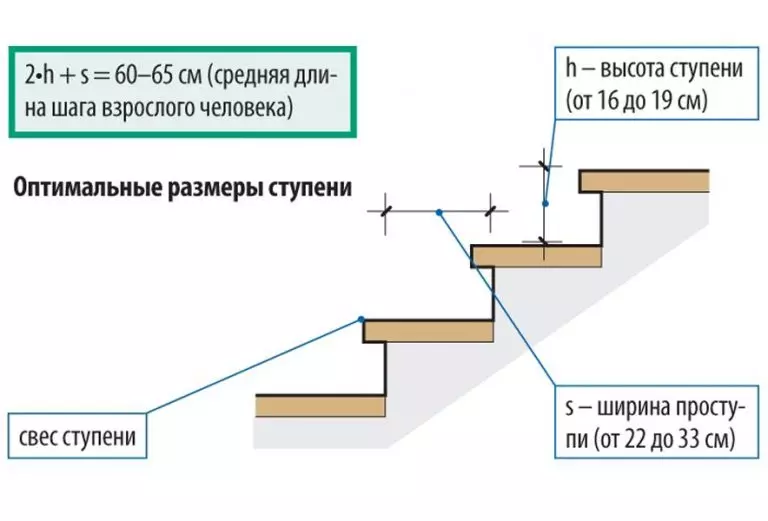

Steps parameters determine the comfort of human movement on them. The height should be so that it is not necessary to raise the leg too high, and the width must match the size of the foot. All these moments are analyzed and displayed in regulatory documents.

The optimal parameters of the steps are considered: width - 20-30 cm, height - 16-19 cm.

On video: Types of concrete stairs, dimensions of steps and the calculation of a simple march.

Creating a concrete monolithic staircase

To pour a concrete staircase with your own hands, you need to make an effort. For a greater understanding of the process, we present step-by-step instructions for the construction of a two-day concrete ladder with an angle of rotation 90 and a platform.Preparatory work (etching of formwork: Start)

After the calculations and the definition of the design type, the formwork is embarked. The example of a concrete staircase is installed in the corner of the room at the wall. In this case, the profile location labels are applied to start. The lower line coincides with the placement of the formwork. Start building a formwork frame.

The assembly is executed according to the following instructions:

1. The beams are installed. All monolithic design will be based on them, so they should be 50 × 150 mm. The end parts of the beams are cut under the desired angle. The length of the details must correspond to the size of the lower base of the stairs to its site. Mounting the beam on the wall is necessary below the lined line on the plywood sheet thickness (approximately 15 mm). The fastening of the beam is better to perform by means of aging for a concrete with a length of 150 mm.

2. Install the supports under the beam. It is necessary to place them in increments of 0.5 m. One of them is a common under the beam and the pad. Therefore, it is necessary to install it with the protrusion half the width of the board. Support needs to be properly cut: one edge is trimmed at right angles, and the second corresponds to the corner of the stairs. The length of each support corresponds to the distance from the floor to the beam in the place where it will be installed. The upper end joins the beam by self-drawing, cursed at an angle.

3. Getting started to the device deck formwork. To do this, the second beam is installed strictly parallel to the one that is attached to the wall. To accomplish this task, the bar is attached at the same place with the same location. It will serve as a support for the transverse crossbar of the deck. The crossbars are installed in 30 cm increments. Their purpose is to hold the OSP leaf along with concrete.

4. From the beams form a frame of the letter P is the base for the staircase. Two details are attached to the wall, and the third to the end of the beams. Supports are installed under it and free beam - the outer side of the formwork. In order for the racks randomly shifted during the fill process, they need to be fixed with a common board at the base of the floor.

5. Mounted jumpers under PSL on the site. In order for the weight of the concrete, they did not get better, it is better to build a support for each jumper. All of them are connected by the board of the floor.

6. Getting stuck. For this, the parts of the OSP are cut out the parts according to the exact dimensions specified on the staircase scheme. The parts are stacked on the crossbars and are fixed by the self-pressing of a long 55 mm at a distance of 20 cm. After that, the deck strength is checked, it should not be fed under the high weight.

Article on the topic: Features of living room design with staircase and design ideas | +76 photo

7. Installation and second march are installed. Lands from OSP, the lower part of which is combined with the edge of the formwork. The height corresponds to the intended thickness of the monolith. In the same way, the second march of the stairs is mounted.

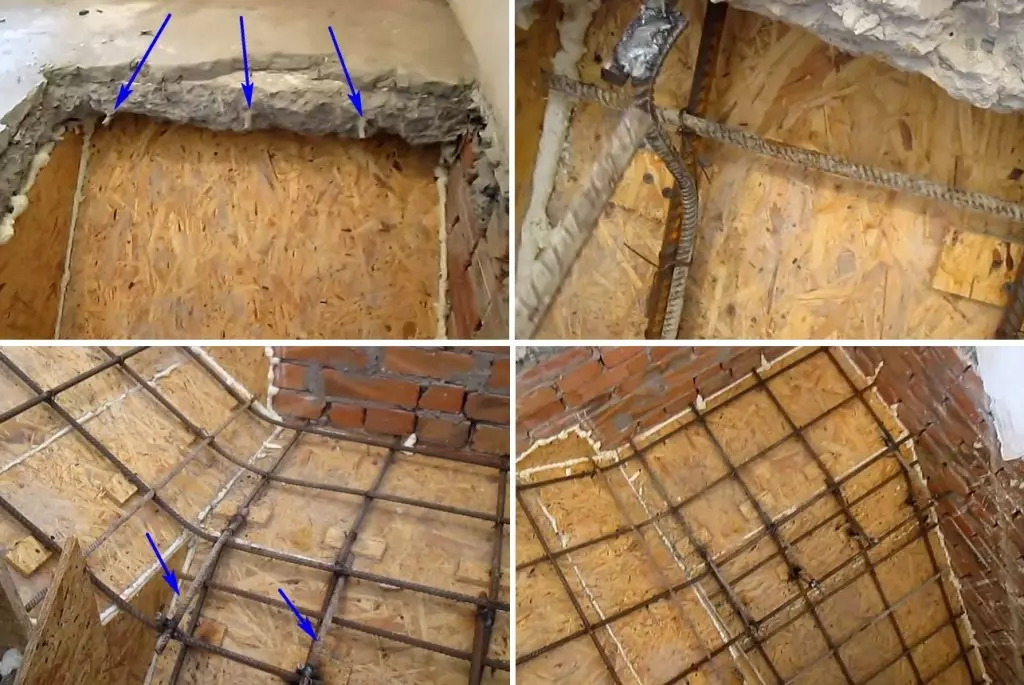

Reinforcement

An important point in the installation of a concrete ladder is its reinforcement. Only in this way it will be possible to achieve the necessary strength and reliability of the structure.Recommendations for reinforcement

Strengthening the design is carried out through reinforcement. It is not necessary to overstat the elements with metal. This does not affect the degree of strength, and the weight of the staircase increases significantly. In this regard, it is necessary to be guided by the standards that say that the total area of reinforcement should be 0.25% of the cross section of the part. Knowing all the indicators, it is not difficult to make the appropriate calculations.

Calculation of the minimum number of rods of longitudinal reinforcement of a staircase march

Start with the definition of basic parameters:

- march width;

- plate thickness;

- The diametral cross section of the reinforcement.

The diameter of the reinforcement is determined by the dimensions of the staircase marches. Up to 3 m is used by a rod with a diameter of 10 mm, and over - 12 mm. On the structure, only corrugated fittings are selected.

Pruts need to be laid with a distance between them in 250-300 mm. These are minimum indicators. Otherwise, small cells will prevent the uniform distribution of concrete. Inside the boards, the bar are placed so that the layer of concrete (and on top, and below) was in the range of 2-5 cm.

To calculate the minimum number of longitudinal rods, you can use online calculators. With their help perform more complex calculations. For example, for a staircase of 800 mm wide and a thickness of 150 mm, using a rod with a diametrical cross section of 10 mm, it will take at least 4 longitudinal rods.

An example of reinforcement of concrete ladder [step by step]

Reinforcement with your own hands requires the correct selection of the material and the execution of calculations. Also performs a high-quality bunch of rods. In this case, the link will be made by a special knitting wire.

The reinforcement process is:

1. Along the deck there are 4 rods with a diametrical cross section of 10 mm in this order: on the sides of one bar at a distance of 7 cm from the edge and two with a uniform step between them. The step between the rods turned out 220 mm.

2. Under the rods it is necessary to provide supports that would contribute to the location of the frame inside the monolith. The masters come out of this position in different ways. But it is best to purchase special polymer racks.

3. Turning to the site, the bars bend, and the ends are becoming at the prepared holes in the wall. Often, the masters are all twigs at the walls.

4. Next, the installation of transverse rods. They are located so that the resulting grid turned out. Linking in places intersection of longitudinal and transverse reinforcement reinforcement is made by knitting wire.

5. Next, the process is repeated on the top march. To do this, first exempt the ends of rods from the overlap and bend so that they can be accepted for top-level. The rest of the process is no different from what was on the lower march.

On video: frame of monolithic stairs.

Completion of mounting formwork (installation of precision partitions)

After the reinforcement, it is embarked on the final process of the formwork device - the installation of partitions, which, after filling, concrete will become the basis for the risers.

The work is as follows:

1. To begin with, the panels will be cut off, which will serve partitions for steps. The size of the panels fully correspond to the height of the riser and the width of the march.

2. Then three more details are prepared from 50 × 150 boards: the reference part, the dimensions of which are equal to the size of the panels, and two sections of 100 × 150 for fastening the jumpers to the formwork.

3. The jumper mount can begin with any position - from above or below. On the formwork on the formwork, markup is applied to relieve mounting.

4. First, the boards with segments are connected, and then to the sides. Inside placed jumper. After installing each part, you should carefully recheck the dimensions, install the backups.

During the installation of formwork, with you, you need to have a mounting foam. It is close to the resulting gaps so that the concrete does not flow.

Pouring stairs

After installing the formwork, go to the concrete fill. At this stage of work, it is also necessary to clearly comply with technology.Article on the topic: Types of stairs to the second floor: Select the appropriate option for a private house (+65 photos)

Filling Silence Tips

The main feature of the fill process by concrete is that it must be done in one reception. In this case, there is no difference, a small staircase or large. Otherwise, the monolith of the structure is disturbed and its reliability and strength are reduced. Therefore, it should be worried about creating conditions for rapid work or order concrete is ready.

In the case of the manufacture of the solution with their own hands, we are determined with its composition. It is best to use concrete brand M-300 or M-250. For these compositions, cement, sand and crushed stone have the following ratio: M-250 - 1: 2.1: 3.9 and M-300 - 1: 1.9: 3.7.

It matters and the fractionality of rubble - 25-30 mm. Larger material will not be able to qualitatively fill the space under the reinforcement belt.

As for the ratio of water and cement, it must be slightly smaller than it is usually approximately 0.6. It is necessary to ensure that the concrete is plastic and has no high yield strength. Experts recommend adding plasticizers to it that are widely sold in construction stores.

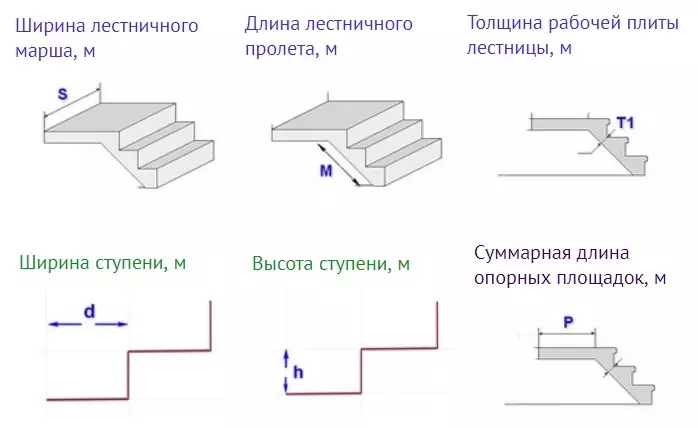

Calculation of the amount of solution [+ example]

Calculate the amount of the necessary concrete solution is simple. We need to remember geometry lessons again. In this case, you need to know the volume of the design. By their form, the staircase can be closer to the rectangular parallelepiped. For calculation, the volume is multiplied by the length of the width and thickness of the plate. The resulting result add a stock in the amount of 10%. Knowing the volume, the amount of bulk materials can be calculated using an online calculator.

You only need to enter certain parameters in the fields. For example, the staircase corresponds to such parameters:

- march width - 0.8 m;

- The length of the span is 2.5 m;

- Plate thickness - 0.15 m;

- Step height - 0.2 m:

- The width of the sticking is 0.25 m;

- number of steps - 9;

- Length of reference sites - 0.6.

Online calculator will issue the following result: you need to order 0.61 m3 already with a 10% margin. In the case of independent manufacture of the solution, 160 kg of cement M-400 brand is necessary; 310 kg of sand (0.19 m3), 600 kg of rubble (0.41 m3).

Stage of the fill of the concrete staircase [step by step]

The formwork is ready, the materials for concrete composition purchased, the concrete time has come. Pour the stairs by following this plan:

1. Fully clean the design from dust and garbage that could get there during the construction of a formwork, it is easier to make a vacuum cleaner. Concrete mixer is better to accommodate in the immediate vicinity of the design, so as not to wear a bit of heavy solution.

2. Start kneading concrete. Fill half the amount of water together with the plasticizer, include concrete mixer. Then add one part of the rubble, it will allow uniformly stirring the contents and separated from the walls with a sticking mixture. This follows cement and sand, and in the completion of the residue of rubble and water.

3. Fills the staircase from the bottom stage, and gradually rise to the upper elements. After the concrete is riveted into the formwork, it is necessary to immediately pin it with a piece of fittings or a trowel. This will help evenly distribute the mixture and expel excess air.

4. The result will be much better if using a special vibrator for concrete. You need to try not to hurt the rebel. Next, the surface is leveled by a trowel, an extra concrete is removed and loaded.

5. After the concrete drops the desired strength, in a few days, depending on the room temperature, the formwork is dismantled, and then polished with a grinding machine with a special nozzle.

Finishing options

For the further use of concrete ladder, it is thought out its finish. For this there is a lot of options. It looks very profitably a tree, it is light and perfectly fits almost any interior. A tree can be separated steps, balustrade, handrails. You can combine with nickel-plated and wrought elements in fences.

Also often use such materials such as stone, glass and plastic. Possible option - cladding with ceramic tiles.

Starting the creation of a concrete staircase independently, it is necessary to spend thorough preparation, especially beginners. Correct calculations, drawing up an accurate drawing, compliance with technologies - the key to future success in construction. All necessary recommendations are presented in this article. In the absence of experience, it is better to start with a small staircase outside the house, for example, make steps on the porch.

Specialist recommendations (1 video)

Different reinforced concrete stairs (54 photos)