The choice of type of pipe bending depends on your technical and economic opportunities. Pipe bender with a drive, electric or hydraulic, more expensive and more difficult to manually pipe bending in the manufacture.

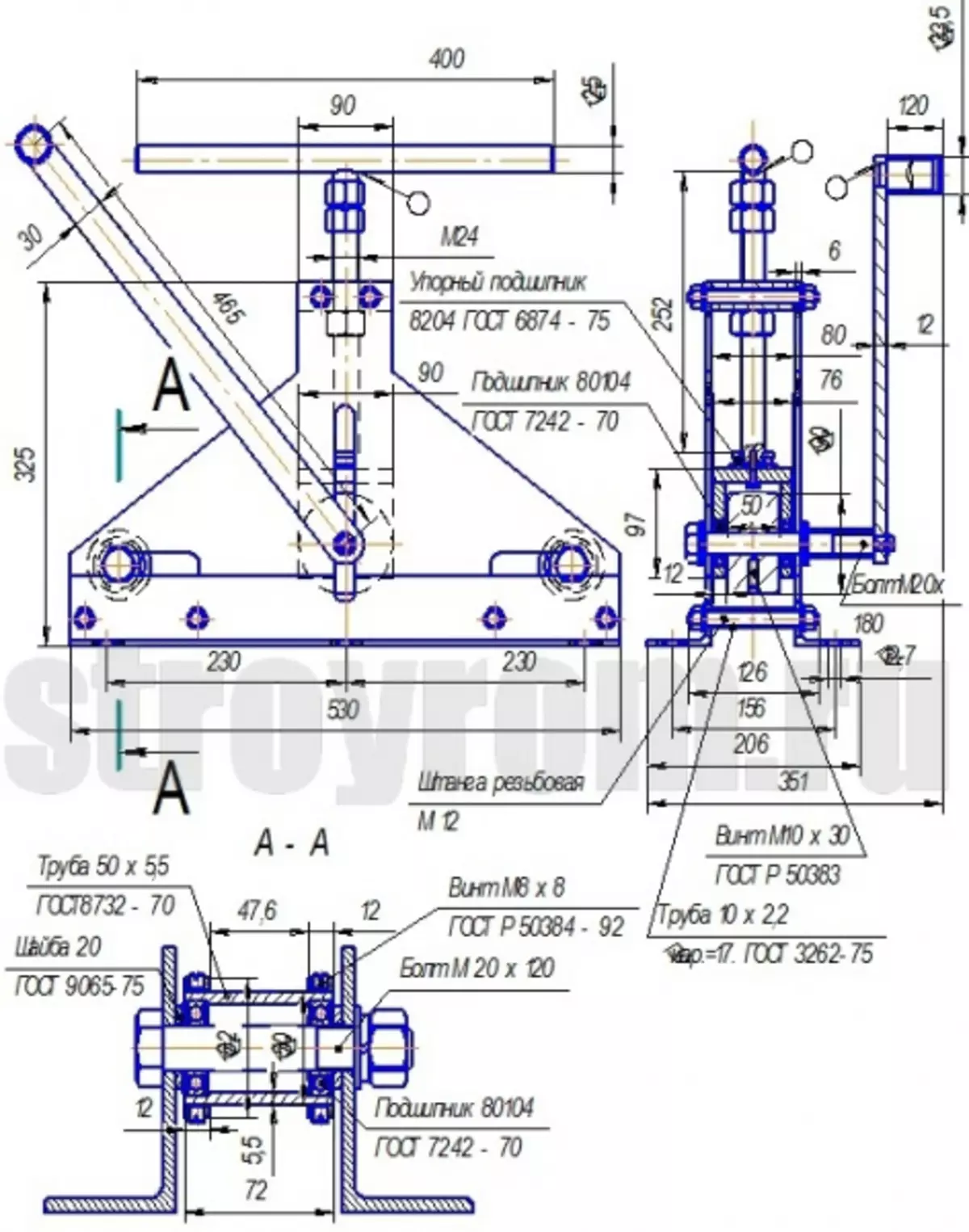

Drawings of pipe-bending

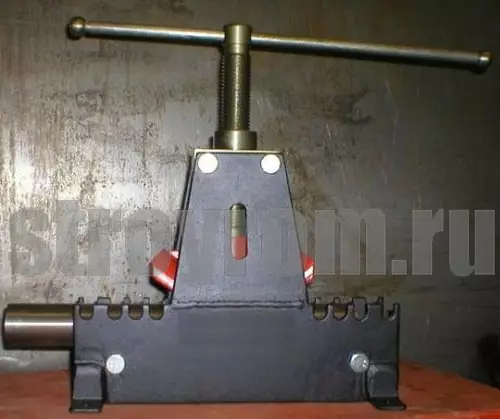

Manual tube bending can be made, even in the garage, and if welding is available to you, then make this device will be much easier for you. Manual tube bending can bend pipe up to 40x40x2 mm. And possible and large sizes.

What major parts and knots consists of this homemade tool? And what are their appointment? This is first cheeks. The whole mechanism is attached in them. In the second videos. Rollers three. The first roller is central bending. This video is installed in a plug, which is attached on the power screw. If the screw is spinning, the central roller will put pressure on the pipe.

There are two more rollers - supporting pipe. The distance between the rollers may vary within the length of the grooves in the cheeks. In our case, the central roller rotates - the handle. Rarlik, rotating, moves the pipe. When tightening the power screw to 1 - 2 turns, the pipe, after each passage, will bend more and more until the desired bend angle is obtained. Several identical bent pipes can be made by installing the nut on the power screw to the right place - emphasis. When flexible the next pipes, the screw will reach only until it stops.

Pipe bender for profile pipe

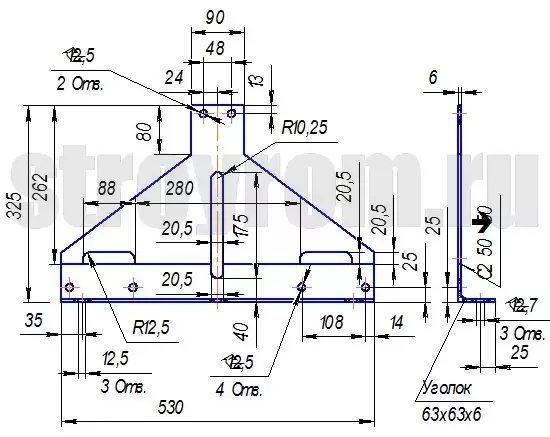

The basis of the adaptation is cheeks. The cheek of the right and cheek left should be strictly symmetrical to each other. Drawing cheeks do not need. Its form is understandable from the description. Consider the cheek right. The billet of the cheek is made from the sheet of steel 6 mm. thick. The billet has a trapezoid form. Lower base = 530 mm. Top base = 90 mm. Height = 262 mm.

On the lower base, you need to cut 2 grooves width of 20.5 mm. One side of the groove coincides with the base of the trapezium. The size between the grooves is 280 mm. The length of each groove is 88 mm. Cut the grooves can be electrolred. To the bottom of the cheek you need to attach a corner of 63 x 63 x 6, a length of 530 mm. Connection method - welding. You need to cook so that the wall of the corner is a continuation of the cheek leaf, that is, the welding of the jack. Now you need to cut another groove - central. The width of the groove is 20.5 mm. The grooves in 40 millimeters from the bottom of the corner begins. Overall Length PAZ = 175 mm. The extreme holes should be drilled, and the sides of the groove can be cut out with an electric bison.

Now it is necessary to perform in the cheek of the hole for fastening with a diameter of 12.5 mm. The axis of the lower 4 holes - 20 millimeters from the bottom of the corner. The first hole is 14 millimeters from the vertical edge of the corner. The vertical axis of the second opening is 108 millimeters from the first axis. On the other hand, the cheek needs to repeat two holes, symmetrically two first. Below the top base of the cheek per 13 millimeters you need to perform 2 more holes with a diameter of 12.5 mm. Between vertical axes of holes - a distance of 48 mm. The axes of the holes are symmetrical relative to the axis of the cheek.

Article on the topic: Morid for wood: Water-based colors, white with your own hands, photo oil and bleached oak, toning

For fastening the pipe bending to the workbench, on each "paw" angle must be drilled 3 holes with a diameter of 12.5 mm.

We are ready for cheeks.

Worker knot

The drawing of the working knot is not necessary. Its device is clear from the description of its work. And the drawings of parts can be made in the form of sketches. The node works like this: when rotating the handle of the power screw, the screw through the nut in the traverse and presses the plug, the plug presses on the central roller, it presses on the profile tube based on 2 other rollers. As a result of this interaction, the pipe begins. The handle of the power roller twists it and the pipe moves. The pipe gets a deflection throughout the go.

An important part of the working knot is the homemade power screw. The basis of it is the segment of the threaded rod M24 x 2. The welding connects the upper end of the screw with the rod segment with a diameter of 25 millimeters and 200mm length. This is his handle. From the other end to the ends of the screw, along the axis it is necessary to cut the thread M10 x 25. This thread for fastening the screw to the fork. Two nuts are screwed to the screw under the knob. These are stops.

The upper traverse must have dimensions: width 82 millimeters, length of 90 millimeters, thickness 25 mm. In the center of it - a hole with a diameter of 26 mm. On the most side you need to make 2 through holes with a diameter of 12.5 millimeters for the passage of fasteners. Distance between holes 48 mm. Below the traverse on the screw is winding another 1 nut and connects with the traverse. Connection method - welding.

Roller design

In this design of the node, the central roller is used homemade, as well as the roller on which it sits. For their manufacture, you will have to contact a familiar turn. And it would be nice to make drawings on them, or at least sketches. The roller has a diameter of 90 millimeters, width 50 mm. The diameter of the opening of 20 mm. It is connected with the type of bearings, which are very convenient fit into the wall of the plug, 12 mm thick. Bearings Type 80104 GOST 7242-70, with two protective washers have the same thickness. These are the most suitable bearings of them will have to buy. The inner diameter of the bearing is 20 mm. The same diameter has a roller that passes through the video. The drive handle dresses on the roller. And so that the video does not turn on the roller, it needs to be secured by three M8 lock screws with a conical end.

In order to make the bottom roller, you need to turn to the turner again. For him, you need to make a drawing, or at least sketch. Tokar is likely to help choose the desired material. It will be necessary to buy only 2 bearings of type 80104 GOST 7242 - 70 per 1 roller, and a bolt M20 x 120 mm.

Assembling corps

Article on the topic: Morid for wood - what it is and how to make it yourself

The body-bending body is assembled on studs of a threaded rod M12 with spacer sleeves. Number of studs - 6 pcs. A water pipe is suitable for the sleeve with an outer diameter of 17 millimeters and a wall of 2.2 mm. Length of sleeves 80 mm. Number - 4 pcs.

By collecting ready-made pipe bending, you can use this device yourself to make such details such as: greenhouse arcs, tables, chairs (pipe 40 x 40 x 2mm.) (Welding will be required), decorative fences, arbors made of metal frame, gate and many other interesting things. of things.