Homemade engine from a washing machine (video camp, photo, schemes)

1. How to connect the engine from the old washing machine through a capacitor or without it

Not all "washing" engines will work with a condenser.

There are 2 main types of engines:

- with condenser start (constantly included by the condenser)

- With a launch relay.

As a rule, "capacitor" engines have three winding outputs, the power of 100 -120 W and turnover is 2700 - 2850 (centrifuge motors of washing machines).

And the engines with the "start relay" have 4 outputs, the power of 180 W and turns of 1370 - 1450 (the actuator drive of the washing machine)

Connecting the "condenser" engine through the start button can lead to power loss.

And the use of a constantly turned on the condenser in the engine designed for a start relay - can lead to winding brave!

2. Homemade emery from the engine washing machine

3. Homemade engine generator from washing machine

Posted by Konstantin.

Today we will talk about the alteration of an asynchronous electric motor from the washing machine to the generator. In general, I have not been interested in this question for a long time, but there was no special desire for removing the electric motor, because at that time I did not see the scope of the generator. Since the beginning of the year, it was working on a new model of the ski lift. Your lift is good, but to ride music is much more fun, so I quickly ripe the idea to make such a generator to use it in winter to charge it to charge the battery.

I had three electric motors from the washing machine, and two of them are absolutely good. Here is one of these asynchronous electric motors, I decided to remake into the generator.

I'll say a little forward, I will say that the idea is not mine and not new. I will only describe the process of alteration of an asynchronous electric motor to the generator.

Article on the topic: Wooden bed do it yourself: Step by step instructions

As a basis, an electric motor was taken by a 180 watt produced by the PRC of the early 90s of the last century.

Magnets ordered NPK "NPK" Magnets and Systems ", before I have already bought magnets when building a wind power plant. Neodymium magnets, magnet size 20x10x5. The cost of 32 pieces of magnets with delivery of 1240 rubles.

The remake of the rotor was to remove the core layer (deepening). In the resulting deepening, neodymium magnets will be installed. At the beginning, 2 mm core was filmed on the lathe - the protrusion above the side cheeks. Then, a recess of 5 mm for neodymium magnets was made. The result of the rework of the rotor can be seen in the photo.

Measuring the circumference of the received rotor, the required calculations were performed, after which the strip was made of the tin. With the use of a template, the rotor was divided into equal parts. Between risks, neodymium magnets will be passed.

On one pole used 8 magnets. In total, the rotor turned out 4 poles. With the help of a compass and marker, all magnets were marked for convenience. Magnets were glued to the rotor "superclaim". I will say, it's painstaking. Magnets are very strong, they had to hold them tight when gluing. There were moments when magnets were broken, pinched fingers, and the glue was shifted into the eyes. Therefore, glued magnets need to use protective glasses.

The cavity between magnets decided to fill with epoxy resin. For this, the magnet rotor has been wrapped in several layers of paper. Paper is fixed with scotch. Overters for additional sealing of plasticine are smeared. In the shell carved a hole. Around the hole made of plasticine made of neck. Epoxy resin flooded into the hole of the shell.

After frozen epoxy resin, the shell was removed. The rotor is clamped into the cartridge of the drilling machine for subsequent processing. Grinding was carried out by sandpaper medium grain paper.

4 wires left the electric motor. Found a working winding, and the wires from the starting winding cut off. I installed new bearings, since the old rotated tightly. Bolts tightening the case are also installed new ones.

Article on the topic: Charge a car battery correctly

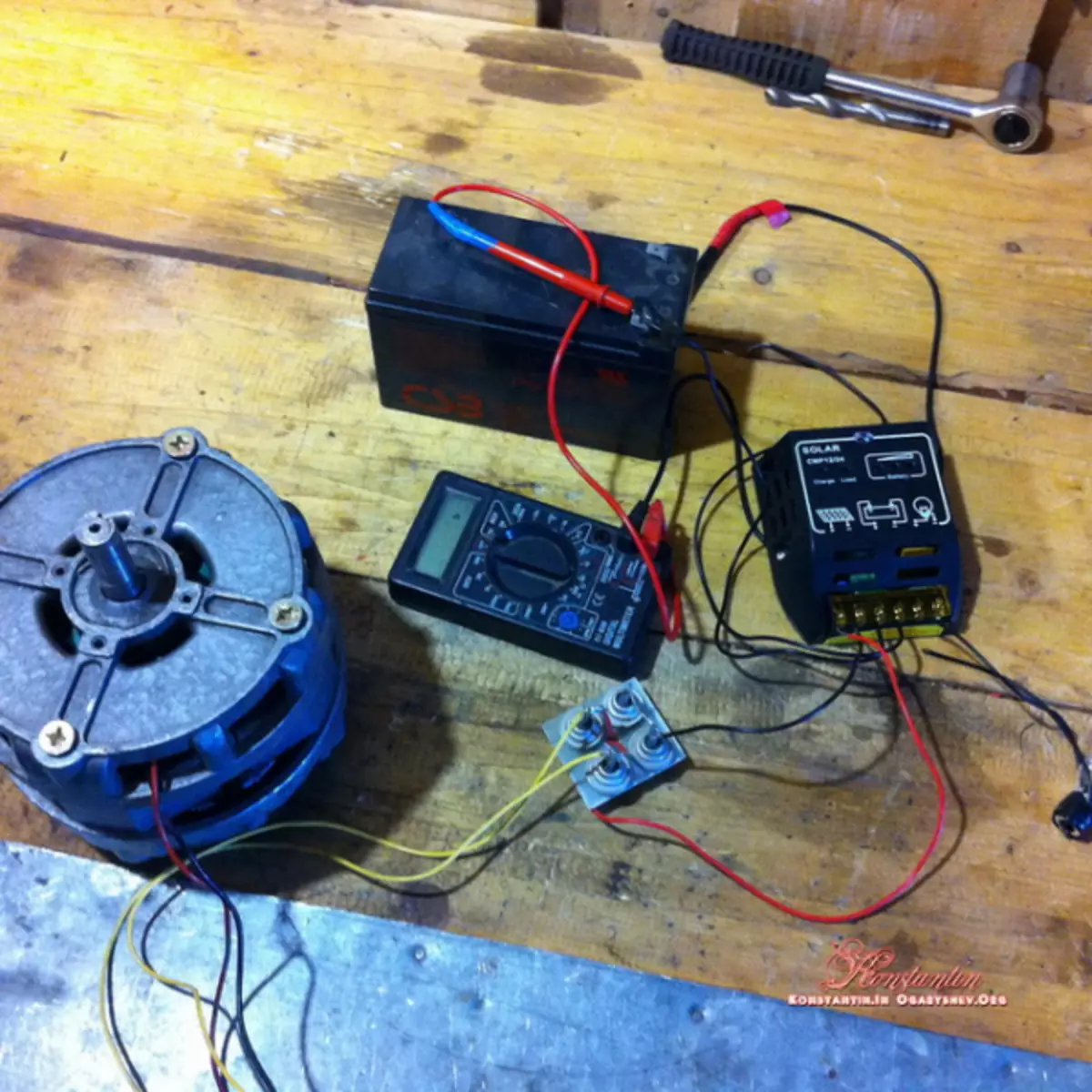

The rectifier is assembled on diodine d242, the "Solar" controller is used as a charging controller, bought a few years ago on eBay.

The generator tests can be viewed on the video.

For charging the battery, 3-5 generator speed is enough. At maximum turnover of drills from the generator, it turned out 273 volts. Alas, the sticking is decent, so there is no sense to put such a generator on the windmill. Is that the windmill will be with a large screw or gearbox.

The generator will stand on the ski lift. Tests in field conditions already this winter.

Source www.konstantin.in.

4. Connecting and adjusting the revolutions of the collector engine from the washing machine

Production of the regulator:

Regulator Setup:

Regulator Test:

Controller on the Bulgarian:

Download:

Engine control CHEMA on TDA1085.zip

5. Potion Circle of washing machine

6. lathe of washing machine machine

How to make an anterior woman with a lathe on a tree from the motor from a washing machine. and revolt controls with power maintenance.

7. Drovokol with an engine from a washing machine

The smallest single-phase, screw column with an engine from a washing machine with a capacity of 600 W. With a roller stabilizer

Worker turnover: 1000-8000 rpm.

8. Homemade concrete mixer

Simple homemade concrete mixer, consists of: Barrel 200 l, engine from washing machine, Disk from Zhiguli classic, gearbox made from Zaporozhts generator, Skifted Large from the washing machine Fairy, small self-pulp pulley, Clean drum made from the same disk.