One of the most reliable ways to connect wires - soldering. This process in which the space between the two conductors is filled with molten solder. At the same time, the melting point of the solder should be lower than the melting point of the melted metals. At home, the soldering iron is most often used - a small device operating from electricity. For normal operation, the power of the soldering iron must be at least 80-100 W.

What you need for soldering soldering iron

In addition to the soldering iron, you need solders, rosin or fluxes, it is desirable to have a stand. In the process of work, a small file may be required and small passas.

Most often we have to solder copper wires, for example, on headphones, when repairing household appliances, etc.

Rosin and fluxes

To get a good connection of wires, it is necessary to clean them from pollution, including from oxide film. If mono-veins can still be cleaned manually, then the stranded conductors will not be able to clean normally. They are usually treated with rosin or flux - active substances that dissolve pollution, including oxide film.

And the rosin and fluxes work well, only fluxes to use it easier - you can dip a brush into the solution and quickly process the wires. In the rosin it is necessary to put the conductor, then heat it with a soldering iron so that the molten substance wolves the entire surface of the metal. The lack of using fluxes - if they remain on the wires (and they remain), gradually corrosive the adjacent shell. That this does not happen, all places of soldering should be processed - wash off the remnants of flux alcohol.

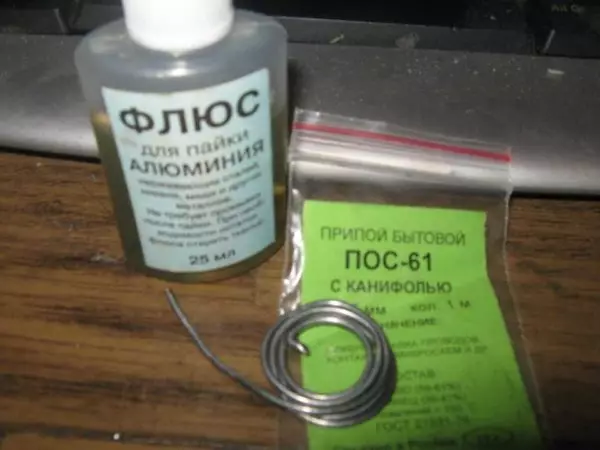

Solders and fluxes for soldering soldering iron copper wires

Rosin is considered a universal means, and fluxes can be selected depending on the metal that are going to solder. In the case of wires it is copper or aluminum. For copper and aluminum wires take flux LTI-120 or Buru. A homemade flux from rosin and denatured alcohol (1 to 5) is working very well, and simply make it with their own hands. In alcohol add rosin (better dust or very small pieces of it) and shake up to dissolve. Then this composition you can process conductors and twists before soldering.

Article on the topic: Repair of headphones

Solders soldering with a soldering iron copper wires are used by 60, piac 50 or pos 40 - tin-lead. For aluminum, zinc-based compositions are more suitable. The most common - CO-12 and P250A (from tin and zinc), brand A (zinc and tin with the addition of copper), Central Assembly (zinc with aluminum).

It is convenient to use the soldier with rosin

It is very convenient to use solders, which includes rosin (PM 61). In this case, it disappears the need to pre-process each conductor in rosin separately. But for high-quality soldering, the soldering iron must have a powerful one - 80-100 W, which can quickly heat up to the required temperatures place soldering.

Auxiliary materials

In order to solder the soldering iron wire, more needed:

- Stand. It may be in a metal fully or on a wooden / plastic stand, metal holders for the soldering iron. It is also convenient if there is a small metal box for rosin.

Soldering the soldering iron more convenient with the stand homemade and factory - not very important

- File. Before work, the soldering iron is sharpening. It must be smooth and clean without traces of Nagar. Then rolls easily.

So you need to sharpen the sorry of the soldering iron

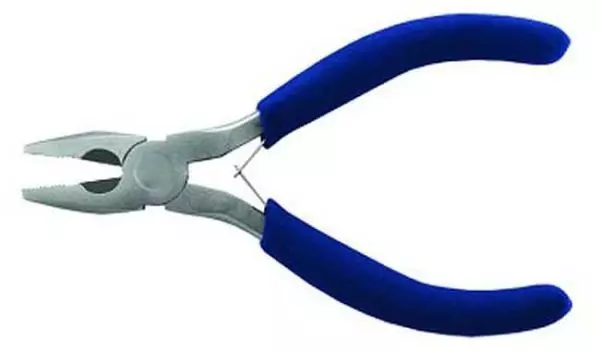

- Passatia. Hold the wires with your fingers during the soldering is difficult - copper and aluminum have high thermal conductivity, which leads to a rapid heating of nearby sites. Therefore, soldering a soldering iron wire is more convenient if they hold them the passage. Only a tool should be miniature, with thin handles and sponges. In principle, it is possible to use tweezers, but on its top (where it is held with your fingers) it is desirable to put on a heat shrinking tube - the steel is also quickly heated.

Passatia - to hold wires

For flux cleaning, alcohol may be required, for insulation - electrical tape or shrink tubes of various diameters. That's all the materials and tools, without which the soldering iron wire is impossible.

The process of soldering the electric pot

All soldering technology soldering wires can be divided into several consecutive steps. All of them are repeated in a specific sequence:

- Preparation of conductors. When soldering wires, they are exempted from isolation. After that, the oxide film is removed from them to be mechanically removed. You can use a small piece of emery paper with small grain. Metal must glisten and be light.

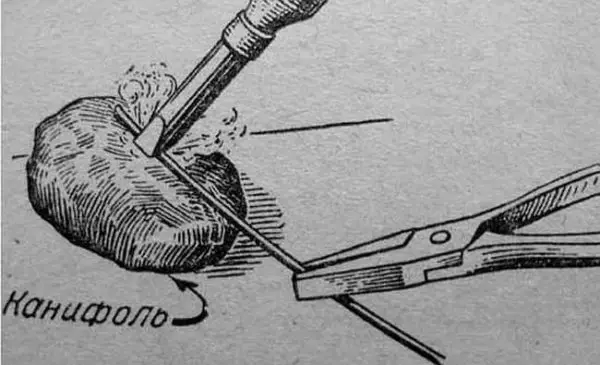

- Tinning. Heat the soldering iron to the melting point of rosin (when touched it starts actively melting). Take the conductor, bring to a piece of rosin, warm the soldering iron so that all the strongest part of the wire is immersed in rosin. Then on the sting of the soldering iron take a drop of solder and spread it over the treated part of the conductor. Solder quickly spreads, covering a thin layer wire. So that it is distributed faster and evenly, the wire turns a bit. After the tinning, the copper conductors lose redness, becoming silver. So handle all the wires that need to be soldered

Substitute residue

- The listed conductors are folded together, correcting them with their fingers - so that they feel tightly alone. If the soldering should be a big length, you can make a twist. Holding the conductors, on the sting they take the solder, press it to the place of soldering, applying some effort. At the same time, the place of the soldering is heated, begins to boil the rosin, the solder spreads. When he covers the entire zone, accounting between the conductors, it can be considered that the soldering iron of the conductors is completed. They are still held motionless for some time - while the solder does not cool down (to speed up the process to this place).

Here, in fact, everything. In the same way, two or more wires can be soldered, a wire can be soldered to some kind of contact pad (for example, when soldering headphones - the wire can be soldered to the plug or to the site on the headphone), etc.

After finished soldering the soldering iron wire and they cooled, the connection must be isolate. You can wind the isolate, you can wear, and then warm up the heat shrinking tube. If we are talking about wiring, you usually advise first to screw several turns of the tape, and on top to wear a heat shrink tube that warm it up.

Differences technology when using flux

If an active flux is used, and not a rosin, the meturn process changes. The purified conductor is lubricated with the composition, after which he warms the soldering iron with a small amount of solder. Further, everything is described.

Skinger with flux - faster and easier

There are differences and when soldering twists with flux. In this case, you can not twist each wire, but twist, then process the flux and immediately start to solder. Conductors can not even be cleaned - the active compositions energize the oxide film. But instead, the soldering site will have to wipe away - to wash off the remains of chemically aggressive substances.

Features of soldering of stranded wires

The soldering technology described above is suitable for monashed. If the wire is stranded, there are nuances: the wiring is spinned before the luggage, so you can enhance everything in the rosin. When applying solder, it is necessary to ensure that each posting was covered with a thin layer of solder. After cooling, the wires are twisted again to one harness, then you can solder the soldering iron as described above - dipping the sting in the solder, warming the place of the spike and apply tin.

When tinning the stranded wires need to "fluff"

Is it possible to solder copper wire with aluminum

Aluminum connection with other chemically active metals cannot be done directly. Since copper is chemically active, then copper and aluminum are not connected and do not solder. Case in too different thermal conductivity and different currents. When the current passes, aluminum heats up more and more expands. Copper is heated and expanding significantly less. Permanent expansion / narrowing in varying degrees leads to the fact that even the most good contact is broken, a toxconducting film is formed, everything stops working. Because copper and aluminum do not solder.

If such a need arises to connect copper and aluminum conductors, make a bolted connection. Take a bolt with a suitable nut and three washers. At the ends of the connectable wires form rings in size of the bolt. Take the bolt, put on one puck, then the conductor, another puck - the next conductor, on top - the third washer and everything fixes the nut.

Aluminum and copper conductors can not solder

There are some more ways to combine aluminum and copper lines, but the soldering does not apply to them. You can read about other ways here, but the bolt is the simplest and reliable.

Article on the topic: Flexible plinth: how to bend for gender, expert advice