The decision to build a house from the bar is not immediately accepted and not suddenly. Just this technology, with a simpler assembly of the walls, allows you to get excellent characteristics for housing: for the Moscow region there is enough timber in 195 mm thick. With this thickness of the outer walls, it will be warm, but it is better to warm it for saving on heating (outside 10 mm minvati) and make a verteautable facade. Then there will be also savings on heating.

Plasticity in processing - one of the advantages of wood

What wood choose

For the construction of the house uses usually wood coniferous rocks. There are several reasons. First, the increased resin content, which are natural preservatives and antiseptics. Thanks to their presence, wood is destroyed for a long time. Secondly, affordable price. You can, of course, build a house from a beech or oak bar, but the price will be simply translated. Thirdly, the wood is soft, easily processed.Of all the coniferous rocks most often put a house from a pine bar. With good characteristics, it is relatively inexpensive. Houses from larch and cedar rarely put: too expensive. From ate even less often, but for another reason: it is faster than all collapse, and even heavy in processing. So relative to the breed of wood, choice, actually, and not. In 95% it is pine. But with the type of timber it is necessary to understand.

By processing method, the bar happens:

- Normal or whole, unstage bar. Heated from a solid log, section - quadrilateral (square or rectangle).

- Profiled timber. It is also pumped out of a solid log, but after it is processed: the stubs are formed by spikes and grooves - profiles, with which one bar is docked with another. Side faces are also processed. From the machine they come out already laughing. Section - complex shape. Side faces can be smooth, rounded, curly - with chamfer, the form of "locking" - numerous beards and recesses.

- Glued bar. Externally similar to profiled, but assembled (glued) from several boards.

We will analyze the features of each of the types of timber, relative to the construction of the house.

House from a regular bar

If earlier it was said that they decided to build a house from the bar, they definitely understood the usual rectangular timber. Other simply was not or was it too expensive: he was brought from abroad. The usual bar is the most affordable time if you take the cost per cubic meter. But, as a result of all the required events, the cost of the construction may be higher than from the profiled. It's all about the features of the material. They lead to significant additional costs at the stage of construction: when erecting a house from an unstrooty bar, an interventical insulation is necessarily used. He has a non-ideal geometry, and, if this does not do, blow through the cracks between the crowns will be sooooo strong. The second feature is the surface of the walls, it turns out uneven and without finishing inside and outside can not do.

It looks like this usual timber

In addition to laying the interventovation layer, the concoated log house supplied, additionally sealing seams. Canopate is not alone, but at least two, sometimes more. And all because it is made from the wood of natural humidity. In practice, this has the following consequences:

- A folded house should have a long time to stand without finishing. The desired time of exposure is about two years. And the first year, the roof does not put or rear a rafter system, cover the membrane and leave in this form. In the second year, the roofing material is laid. During this time, wood dries, the walls "sit down" and can be searched for finishing work.

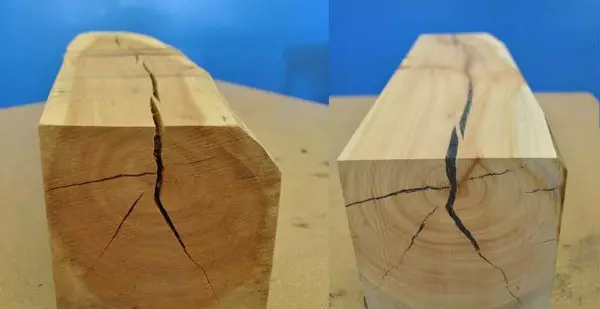

- When drying, the natural humidity bar is severely cracking. It is sometimes formed very deep and wide cracks, which then also have to be caught. In the worst case, end-to-end can appear. There are some more troubles: the bar can "lead": unscrew into some kind of side. All these processes are natural for wood, but they must be borne.

Cracks can be deep

- Lumber of natural humidity is strongly susceptible to rotting and blue. During delivery, wood darkening process can begin. Therefore, the bar must be folded into the ventilated stacks, and under the lower rows to lay lining. In addition, it is necessary to process wood with protective impregnations (antiseptics) and antipirens before laying in a frame. It is necessary for all the wood, simply at high humidity there are high requirements for processing quality.

Another feature of the house from the usual timber: walls are irregular. To give them a "decent" species, they are either trimmed with finishing materials, or grind. But grinding is a controversial approach: the inter-night seal makes it almost impossible. Even if you manage to polish the bar, where to give the seams?

So it turns out that the cost of the house as a result can be greater: to the cost of a bar, add an interventical insulation, material for cacopa and the work itself (and it is not available), the cost of external and interior decoration. Consider also bringing to the plot to you, the bars of the ordered length. Bowls are peeling in place. This means that the qualifications of carpenters must be high. From how there is a word, it depends as warm the angles will be. And in the brusade house it is the corners and are the most problematic place.

About the technical features of the decoration of a wooden house read here.

Features of the profiled bar

Considering the profiled bar, the first thing that rushes into the eyes is almost perfect geometry and smooth surfaces. In any case, it should be. With good quality execution, the finish is not needed: the wall immediately turns out to be smooth and smooth, even at least under painting.

The second, also a fairly obvious feature, - due to the fact that the edges that two profiled timber join, have removing and protrusions (locks) of through slots can not be. Manufacturers of a profiled timber say that the walls can be placed without interventory insulation: it will also be so warm. But few of them listen. Put at least a thin but insulation. Someone uses a thin substrate under the laminate, someone self-seeping tape for mounting plastic windows, as well as jute tape and similar materials.

Between the bar, a substrate for laminate

In the photo, by the way, the most common profile has recently in developers - "Comb." It can have a "tooth" of different heights and widths, and love everyone for the fact that it is impossible to blow it. Nevertheless, and here it is customized, laying insulation.

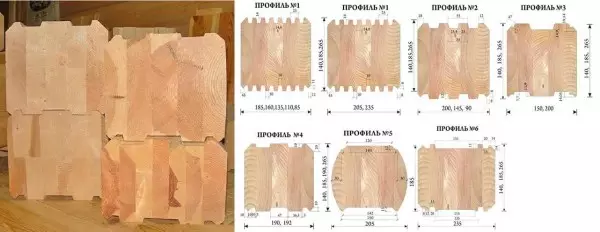

Several typical bar profiles (two extreme on the right in the picture - glued bar, but exactly the same profile make profiled from the array)

In general, profiles are a lot. Some of them - in the photo. When choosing a supplier, it is necessary to pay attention not only to the shape of the locks, but also on how they are completed. The coincidence in any pair must be maximum.

After making the decision to build a house from a bar with a profile, you need to decide on its humidity. The profiled bar is natural humidity (cheaper), there is a chamber drying with humidity no more than 14-16%. The peculiarities of the lumber of natural humidity have already been considered, now let's talk about chamber drying. The company establishes large drying cabinets in which the finished profiled timber is loaded. There, in conditions of elevated temperatures, it loses excessive moisture. At the same time, all processes occur in the chamber, which usually accompany the drying of wood: it bursts, it twists. Accordingly, part goes married, and the remaining sold at a higher price. Causes, it seems clear.

If you decide to build a house from a chamber drying bar, you can start the finish before. The log house should still stand out, but it will be necessary for it 9-12 months. At the same time, new cracks are rarely formed, only existing ones are expanding. But it should be borne in mind that due to the high costs for drying, most often only reduce humidity to operational - 16-18%, while the chamber drying is considered to be 8-12%.

In any case, sealing gaps. Konopka is needed in very limited volumes: First of all, you will have to view all the angles and wrestles, if there is (so called the places of fastening of the places). Even well-made bowl when dry can be uneven, because of which the gap will appear. Also, the timber can turn out what will lead to the appearance or expansion of the gap. So the periodic audit of the angles is also required during operation. Wood - Live Material, and all the time will change something. Also, after a year of sludge, it will have to make too large cracks in the bar (without fanaticism so that the panel does not spread the crack).

The log house is assembled from numbered blanks with a molded bowl (the numbers are blue on the ends)

It can be easier to face the assembly. If you just order a sawn timber, cutting the angles from the profiled timber, as from the usual, can be on the plot. But many enterprises, in the presence of a project, offer part of the work to take over. With the help of a special program, make a layout of Brus: compile a list of "spare parts" of which the house will be collected. Then the blanks are cut on this list, and with molded thumbs. The billets are numbered and ready to be brought to the site, where the house remains to fold, like a designer: folding the bars by numbers marked on the plan.

It is convenient, especially if you are going to cost the house with your own hands without construction experience. It is clear that the service is not free, but you can save money for payment of carpenters: it is not required to collect such a high-qualification designer. Only in this case is warm or not there will be your home depends on how the bowls will make exactly at the production. Sometimes there are firms that make very poor-quality drums. Several of these you see in the photo.

Poor-quality made bowls - blowing will be incredibly, and caulking badly save

In general, there are its disadvantages and its advantages, but compared with the usual bar, profiled more convenient in construction, and at a price can also be cheaper, if you count with the finish.

About the features of laying wiring in wooden houses, read here.

Glued bar

By title it is clear that it consists of glued parts. First, the lamellas are peeling, they are treated with antiseptics, dried to a certain humidity, then glue. Due to the complex manufacturing process, the price tag has about 2.5-3 times higher than that of the usual and 80-90% of the profiled.

What is his advantages? Properly manufactured, it does not crack, it does not lead it: drying in dry material can not be, and glued boards should have a humidity no higher than 12-15%. Therefore, the process of finishing, with sufficient to compensate the heat loss of the timer, can be given only to painting or varnishing, since the protective impregnation is carried out at the enterprise (must, in any case).

What does glued bar and its profiles look like

Another consequence of the lack of drying is a folded log house after a few weeks you can immediately put under the roof, and in a few weeks you can start the finish. This time is necessary on the shrinkage of the cup, and the geometric dimensions of the glued bar should not change. That is, it turns out a significant savings of time - everything, including finishing work, can be made in one season.

But is it good for glued beads? From the point of view of the speed of construction - yes. But he has serious shortcomings. The first: it was glued. What turns out one of the main advantages of wood - environmental friendliness. The second is low permeability. Many put wooden houses precisely because of their ability to naturally adjust the humidity in the room. The glued bar due to the presence of layers of glue this is deprived. Of all the advantages of wood, only an attractive appearance remains, but the house of aerated concrete, carved by the lining of the corresponding profile or block house, looks likewise. Therefore, using the glued bar for the construction of the house - the question is very controversial.

The design of the wooden house design is described here.

Stages of construction of a house from a bar

Brusade house has several advantages:

- The walls are obtained lungs, which is why the load on the foundation is low, which means that the costs of its device will be lower.

- Wood - The material is elastic and small basement of the foundation. It compensates without prejudice to the integrity of the building. And this is again the same, it allows you to make small-breeding foundations on well-draining soils.

The choice of the foundation type depends in many respects from soils, but most often make a ribbon foundation, if there is no need for the basement, you can put a column (for small builds of temporary residence - cottage, bath, etc.) or pile (with woodwork or without). The choice is desirable to base on the results of geological research. More The process is described here.

While the foundation is "grasped", prepare wood. The entire timber and brazen are treated with antiseptics and antipirens. Use compositions that do not form a film on the surface surface. They will not interfere with the drying process. After training, the bar begins the entry of the house:

- Cut-off waterproofing. So that the wood from the foundation does not pull moisture, it is necessary to pave a layer of hydrophobic material. Previously, two layers of rubberoid laid under the first crown. Today there are more modern materials - coating and rolled. You can use them, and in combination: to deceive, stick roll.

- Laying a groin crown. The timber is chosen without signs of blue, with a minimum number of bitch. It is desirable - from the middle part of the tree - with the maximum density of annual rings. It is treated with additional impregnation, designed for wood, which is in direct contact with the Earth. In order to ensure the best preservation of the first crown, there is a trick: a wide board is stacked for waterproofing, impregnated with bitumen mastic with a working on. It is still laying a layer of waterproofing, and from above - already the first crown. All these layers are associated with the foundation of studs that are filled in the foundation.

- Rough floor. Floor lags are fixed to the first crown - a timber section with a cross section of 150 * 100 mm. From stacking at least 70 cm in increments. To make it more convenient to work, the draft floor boards are unfolded by lags, without navigating them.

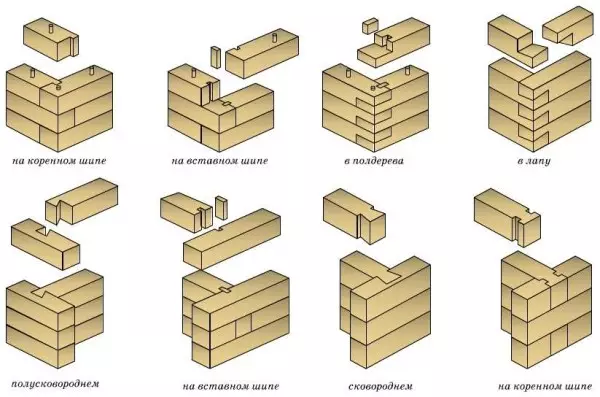

- Assembling walls from a bar. If the wall kit is not ordered with ready-made bowls, they are "killed". Cut down the template. From a piece of plywood, the pattern is drawn, it will be drunk, then cut down. More often use chainsaws, but a fairly high degree of ownership of the tool is required: the accuracy of the execution of the execution depends on how warm the house will be. Forms of connecting timber - in the picture.

Methods for connecting timber

The laying of the interventory insulation has already been told: when using an ordinary timber, it is obligatory, under profiled - desirable in the bowl, the rest is at will. Between themselves, the crowns are connected by molecules - long round bars, painted from a solid piece of wood, ducts - a rectangular shape or stiletto - metal rods. In any case, the hole is drilled by a hole in which the connecting element is clogged.

- Assembly of the rafter system. The order of work depends on the type of the chosen roof. When a simple bartal roof is installed, entropulous legs are installed, when the indoor floor is the order of the other. A windproof membrane is rolled up on the collected rafter system. In this form, the house is left for a long period of destruction.

- Door and window openings. For the speedy dermiska and shrinkage, you can cut window and doorways, put the chain or fixing strips. Door and window blocks until the end of the main shrinkage does not put.

Upon expiration of the year, two can be searched for finishing work. All the time until the log house is defended, it is necessary to track the processes occurring in the wood. Immediately it is necessary to inspect the corners and, if necessary, to cross them. Then track the status of them, as well as timber connections. If brazed up with a lot of effort, the timing can hang on them, because of which the slots are formed. You can solve the problem with a breakdown: take a huge wooden hammer and knocking on the walls, causing a faster shrinkage. The same reception is used if the house is too slow.

The video shows the main stages of how to build a house from a bar. Despite lyrical deviations, a lot of valuable information.

How to build a house from a bar: photo report

Built such a house.

Almost ready

We ordered a wall set on the project, a belt foundation is filled under it.

Ready Foundation

Brought blanks with stuffed bowls. They were neatly unloaded, while examining for flaws. One bar was problematic - he was in the middle of a bundle and suffocated - he was covered with a fungus postponed on a separate "treatment". The rest were covered with impregnation (Valley of the Love) and folded in the stack.

Work more convenient to a wide brush

So that there were no problems with fungus under each laid gasket - boards lying across.

The timber is folded into the ventilated stacks so that

Also purchased the rolls of the insulation and braid. The copper was sent to swim in the impregnation. In the old bath poured impregnation and left them for half a day, then got it and dried.

Insulation in bays and braided

On the waterproofing laid on the foundation, the first crown was laid - half-breed. He has no grooves at the bottom.

Laying and alignment of the first crown

It was attracted to the foundation with anchors to the stiletto poured into concrete.

Under the nuts cut out shallow holes

Put the first crown. The one that previously fastened on the foundation is called "zero".

On zero, the first crown was laid

We are diagonally. In order for the cups to fit without problems and there was no skew, they should be equal. Permissible skew - a couple of millimeters.

We move the diagonal, if necessary, move

Aligning the diagonals, drills the holes for the sewage. So that there are no holes more / less than it is necessary in length, the leather-limiter planned on the drill.

Drill length limiter))

Under the bar put the insulation, but on the recommendation of the Finns of its edge "do not get" to the edge of the bar. So he will not pull moisture from the street.

Insulation already than the timber

Walls gradually grow. In checkelling order, they fasten them with anticipation.

We fold the walls

In general, the bar is more or less normal, but there are problems with incorrectly washed cups. When putting a bar, we get a huge gap. Fight it - only manually customized cups to go all exactly.

There should be no cracks. One bar must go to the second without gap

It takes a lot of time to eliminate these inconsistencies, but all the walls are gradually laid out.

Walls made of profiled timber

We proceed to assembling the rafter system. First, as is customary, two extreme farms are installed, then everything else, on the project.

Assembling a rafter system

The finished crate was chosen to rubberoid. So leave the house to dry.

Almost ready

Inside, we lay the blackboard boards, feeding each fifth. They will be dried with the house.

Black floor just laid

Video on the topic

Errors that are allowed during the construction of houses from the profiled bar are described in detail and disassembled in this video. Very helpful. Look.

Article on the topic: how to make a cottage cozy inside and outside: ideas for home and garden (50 photos)