In a country house, do not do without a marching staircase, this element of the interior allows you to competently zonate the room and facilitate access from one room to another. There are two main types of staircases: on governments and cosos. The selection of this or that option depends on the set of factors (area of the room, the financial capabilities of residents, personal preferences, design specificity).

The first type is a classic model and that is why it has a number of indisputable advantages. In this article, we will look at why it is better to choose a staircase on the growths, how to make it with your own hands and avoid errors when marking and mounting.

What is a string for the stairs?

To date, there are several different ways to assemble staircases. Some require professional knowledge and skills, the installation of others is easily and fast. The category of simple in assembling transitions includes stairs on assets. However, before the start of studying the principles of construction work, it is worth understanding that it seems to be a string for stairs.

Under the guards for the stairs, it is customary to understand the support support of the staircase in the form of beams with special grooves or nests located on the inside. The main advantage of this type of fastening of the steps is the "closure" of the ends, which in turn makes the finished product even more attractive.

A string for wooden stairs is the most versatile fastening option. It can be made even to a novice master, and special impregnations will increase the service life of the coating. Wooden stairs are most often found in private buildings, and for public institutions choose more interesting models from materials such as plastic, stone, metal. Different breeds of wood can also alternate.

ATTIVA as the base of the staircase design

Understand what the ladder is just just just, just look at the end of the product. This element is a supporting beam with grooves of certain sizes, in which the steps will then be mounted. According to the majority of experienced builders, it is theater that is responsible for the strength and durability of the marches.

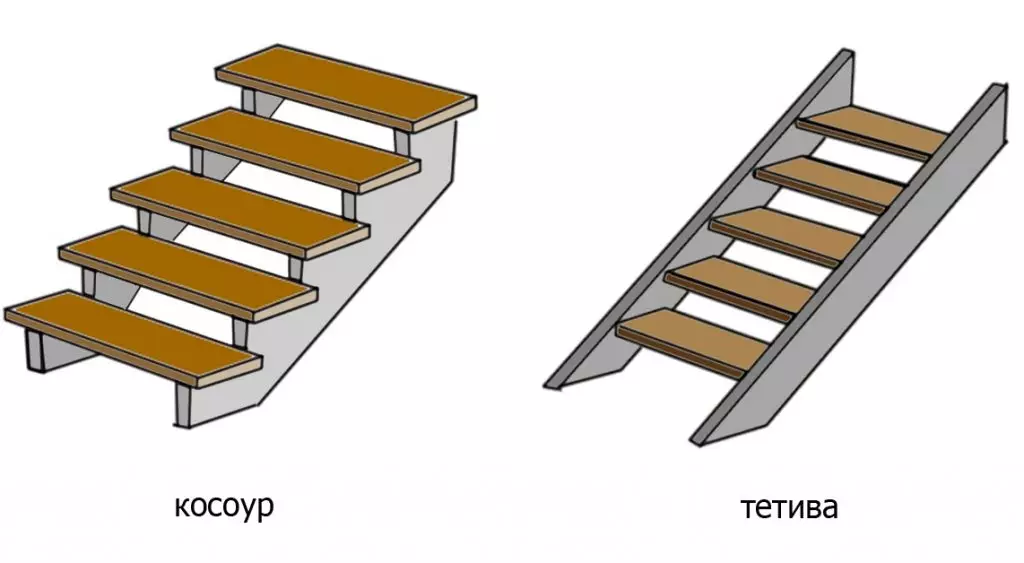

The valid is a peculiar base of the staircase. Below in the photo shows the external differences of two popular fastening of steps (on the tutor and on the Kosoo).

As can be seen, Kosur is a curve beam that fixes the level from below. To increase the strength of such fixation, special propuls are made. This option is best suited for small rooms, as it is characterized by a large bearing capacity and saves free space. Staircases on the growths are more massive, but thanks to the design features, they are easy to manufacture and are absolutely safe in operation.

Please note that there are different types of stairs: straight, curved, spirals. When choosing, the operational characteristics of the future march should be taken into account.

Material and dimensions

The first stage involves the choice of sawn timber in accordance with the established dimensions of the future design. For this, the construction plan is made in advance and the project creates. Ultimately, you should have a one-piece beam without splicing. For the manufacture of the base of the staircase, various wood, metal and reinforced concrete can be used.

Article on the topic: Features forged stairs: species, advantages and manufacturing technology | +55 photos

The preferred material for self-making the staircase is a tree, the breed uses a variety of ways:

- Coniferous wood, such as pine, cedar or spruce. These are budget and reliable options. But the main disadvantage of such materials is the gradual isolation of the resin, which can interfere with uniform staining and subsequent varnishing of the span.

- Deciduous wood, such as cherry, beech and oak. This is the most optimal option. The most reliable are products from oak, they also do not require special care. With careful operation, such stairs will serve your family several decades.

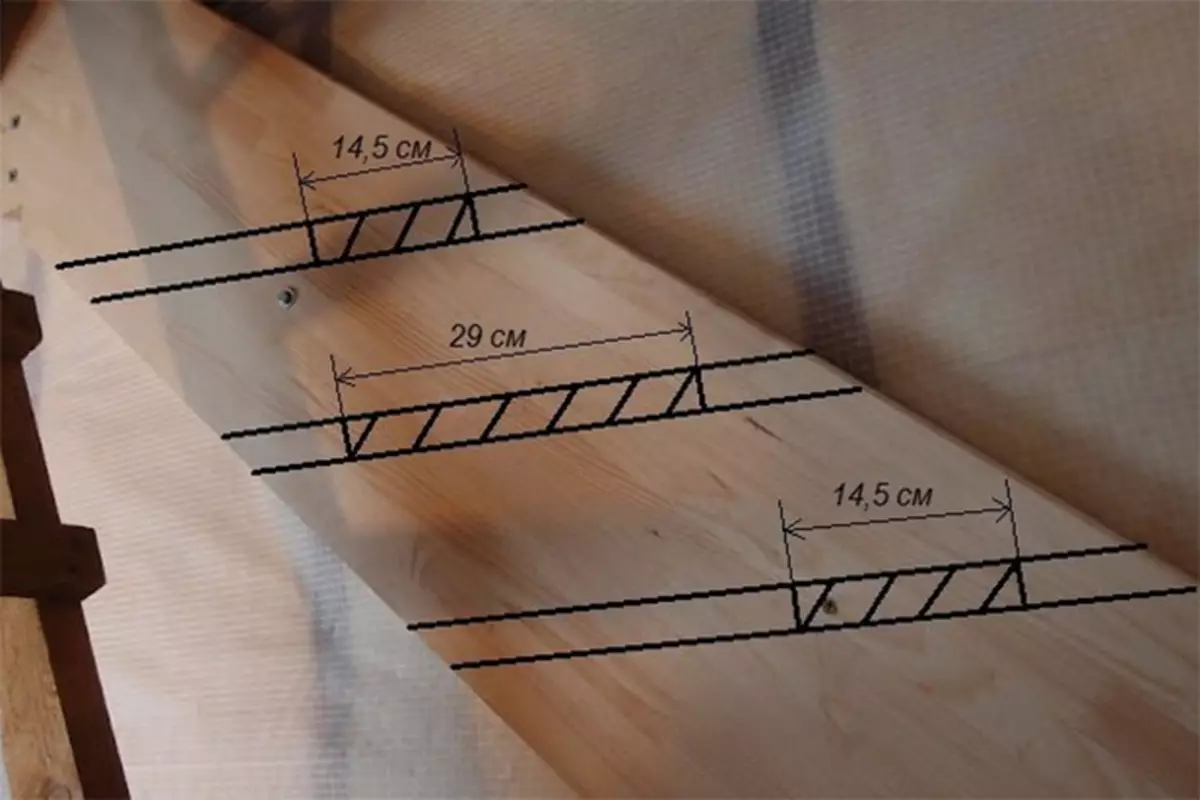

If you are only planning the production of the staircase, you can determine the length of the lantern on the basis of the staircase. The width of the theater should be about 30 cm, the thickness is 4-5 cm.

Marking the Tetiv

Next should be marked by the base of the staircase, considering the actual number of steps (in most cases it is less than the calculated indicators).

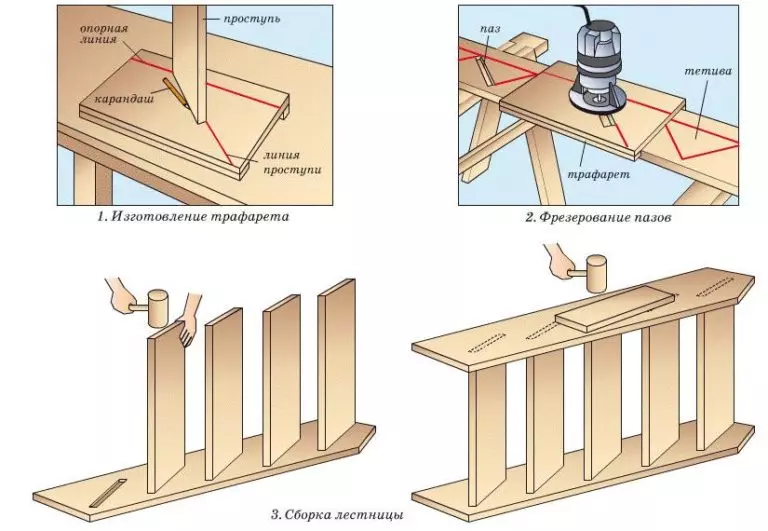

Marking can be carried out in two ways:

- using a construction corner or ruler (the likelihood of error);

- Using a special template.

At the beginning of the work it is especially important to determine the preferred option for the location of the steps relative to the base of the structure.

You can stay on the classic markup method - without a reference line (then the groove remains open), or make sockets closed (that is, to reproduce the reference line at a distance of 4-5 cm from the edge of the workpiece). Both methods are great for self-assembly of the staircase, so the selection of one or another option depends only on your personal preferences.

On the video: the markup of the gadgets do it yourself.

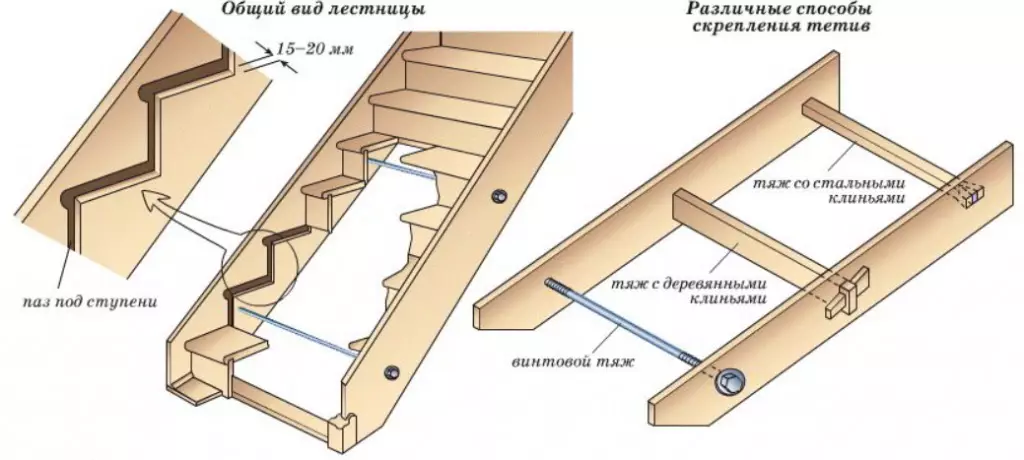

It is worth noting that in the manufacture of a wooden staircase with their own hands, you need to know how to avoid the divergence of the theater. For this purpose, certain fasteners are used.

The latch for the latch can be attributed to:

- Metal trample with wedges. They are reliable, durable, not suitable for compact designs.

- Wooden trenches with wedges. Such elements are quickly supplied to wear, but are simple in production.

- Screw tape with fixation on the nuts. They are considered an optimal option for fastening the guards.

Payment

By making calculations for the project of the future product, the following features of the staircase should be taken into account:- The angle of inclination march must be within 30-40 degrees;

- The depth of the steps should not be less than 30 cm;

- The height of the feet on average equals 20 cm.

The calculation of the parameters of individual components of the stairs is made according to the formula, which is based on the length of the step. The average length of the human step is 63 cm, when using the formula, we obtain the results of: 63 ± 3 cm (2 heights of the stage + the depth of the stage).

Fastening and installing the tutor

After all the necessary measurements were made and the calculations of the finished design were carried out, the process of manufacturing the marching staircase begins. Before that, you need to purchase all materials and tools that may be needed in the process.

Article on the topic: How to make a rope staircase: ways of manufacturing with your own hands [+40 examples in the photo]

For fastening and installing, the instruments will require such devices as:

- Rubber tip hammer;

- electric logs and drill;

- manual milling machine;

- Roulette, line;

- Construction level and square.

If you are going to fix the tutor from the wall, and this is the best option from possible, then you need to measure the used beam in advance and dried off the bottom. This will allow the tutor to smoothly lie on the floor plane. As a result of perfect actions, it will rely on the transverse beam of the opening, which will increase the strength of the whole design.

To better understand how to make a guy to the wall, look at the video where the whole process is clearly shown.

On video: Installation of the ladder to the wall.

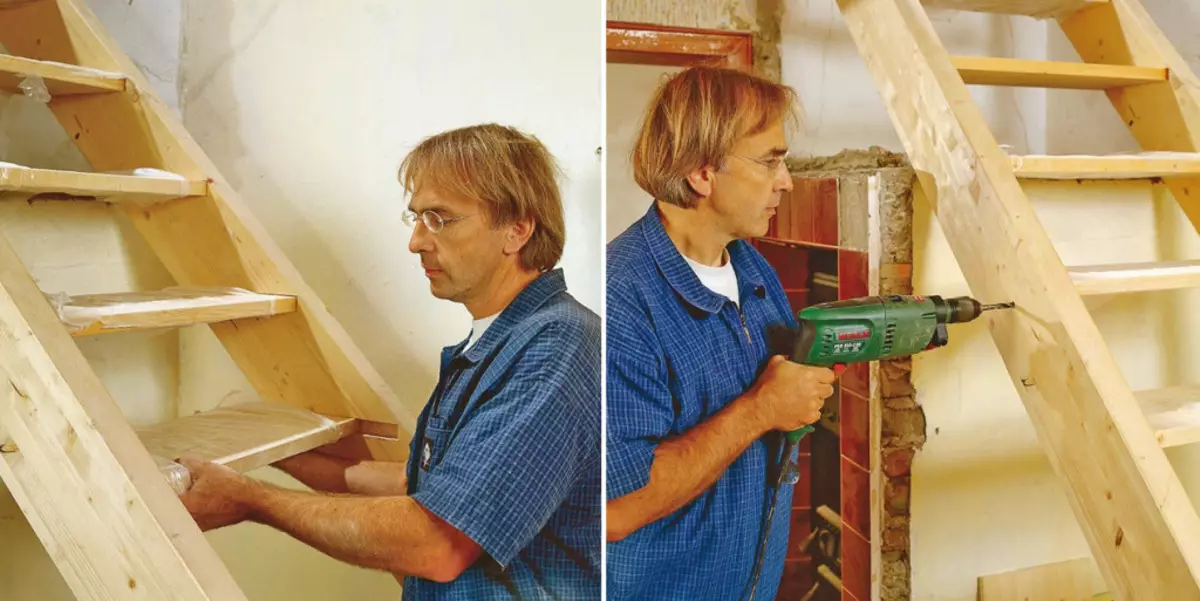

In the manufacture of the stairs with their own hands, the question remains the most difficult - how to mount the steps and make their fit to the ladder. To prevent errors at this stage of work, we recommend that you use the following instructions:

1. The march is collected, after which it is placed in such a way that the actual is down. Next, it is necessary to carry out a flat line on the inside of the upper step and the riser.

2. Another line from the rear of the frieze sticking to the plinth level is made (most often its length is 7.5-8 cm).

3. The following effect involves the removal of the upper risk (and remember that the installation of steps is carried out only at the end of all adjustments).

4. If you are creating a gesture on the floor, then at this stage, tick the line parallel to the bottom sticky, the bottom beams will be distilled.

5. Immediately before installing the stairs, experts recommend to make a recess on the support rack (this will allow the base to fit tight on the upper overlap).

Please note that the installation process of the staircase with bent assets is somewhat different. Before starting construction work, we recommend that you explore the features of fixing steps and watch the video below.

On video: Features of the installation of the screw staircase on the assets.

Wooden staircase on giving hands

After the preparatory stage of work is completed, you can proceed to the most important point - fastening the steps and railings. Next, we will consider in more detail the whole process in order to avoid mistakes. Do not forget that the safety of you and your loved ones depends on the quality of the work done. Therefore, if you are not sure about your abilities, it is better to entrust this work to professionals. To save, select the most simple model of the stairs and inexpensive materials.Advantages and disadvantages

Like any design, this staircase model has advantages and disadvantages of operation. Advantages of specialists include the following important aspects:

- With the help of the structure, it is possible to replace individual sections of the staircase;

- Simple and quick installation of all parts (the main requirement is the accuracy of calculations);

- Wooden models with proper care will serve you and your family for more than a dozen years;

- a wide selection of shapes and sizes (suitable, rotary or g-shaped);

- A variety of design solutions (as an example, it is possible to make the production of steps without oppomme care).

The only disadvantage of this type of construction can be called overestimated requirements for the accuracy of calculations and fasteners. Incorrect design or poor fastening can significantly reduce the reliability of the stairs, which is fraught with accidents. The beams may disperse, step fall out of the grooves, and all your work will go to the pump. Therefore, if the money allows, and security is most important for you, better consult professional.

Article on the topic: How to calculate the stairs to the second floor: optimal parameters

Types of docking

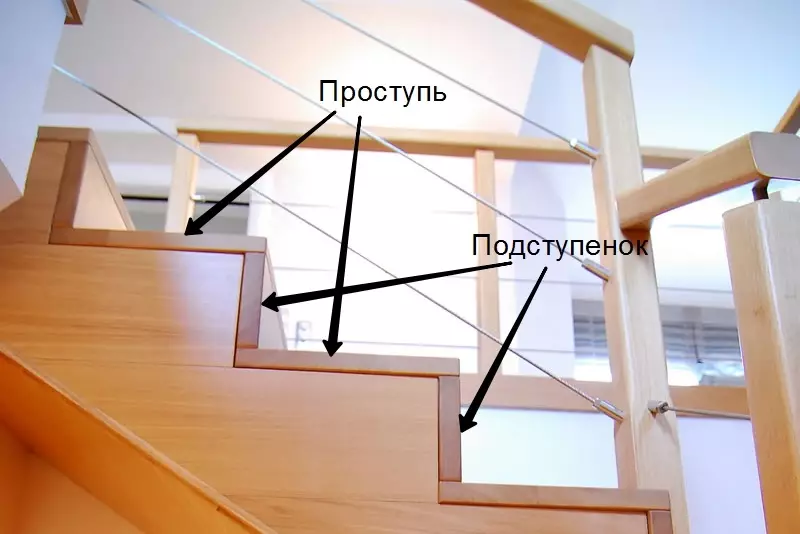

For the manufacture of this type of stairs can use different methods for docking steps and the teta. Properly fasten the details are not as easy, but initially it is worth determining what kind of disposal and risers:

- Precade is a vertical element of the stage necessary to give the additional stiffness and reliability of the entire design.

- Apartment is a horizontal element of the stage, which is based on a person when climbing or descent on the stairs.

Staircases can be without oppressive, but it is impossible to imagine a staircase without sticking. That is why all new and new fastening of steps and the guards are constantly being created. It can be a one-piece level or free option without a risk. Note that the second method is becoming increasingly popular.

Fastening steps

The process of fastening the steps to the tutor is quite simple. The processed and heated stages and risters are inserted into the grooves or screwed to the bars, metal corners. So that the design is not loosened, these details should be done with particular accuracy and accuracy.

Photo of ready-made stairs

A wide selection of materials allows you to make a variety of staircase designs. Wooden models are particularly popular with the cheapness and environmental friendliness of the material. Do not forget about the long service life of wood, as well as the possibility of partial or full repair of the product. Experienced masters make a luxury staircase from wood, which are suitable for any, even the most extravagant interior design.

What is better: the staircase on the growths or cososters?

When choosing a model of an inter-storey staircase, certain problems may occur. Especially often owners of country houses cannot decide what is better - the Taitiv or Kosur. First of all, the external features of the details and its use are taken into account. Kosur is made in the form of a comb repeating its outlines of the stage of the staircase march. Thus, each appearance is attached to the upper face, and the risers are on the side.

Unlike the Kourow of the ATTA, there is even lateral outlines. Such a product looks more neatly, and the steps are practically not visible, since they are inserted into special grooves or are installed on fixed bars. Visually, the staircase on the crosses looks compact, but the design on the tutor is more reliable and safe in operation.

Choosing one or another option, pay attention to the layout of the room and the presence of free space. If the issue of saving space for you is especially acute, it is better to prefer the staircase on the cosos.

Making a staircase on the tutor with your own hands is completely simple, you only need to accurately stick to the specified sizes. All items must be treated in advance with antiseptics, write their dimensions and correctly carry out calculations.

The easiest way to build stairs (1 video)

Interesting models of stairs on assets (44 photos)