Tree - affordable, environmentally friendly material, widely used in the construction and finishing of buildings. However, many refuse him for the reason that with time the wood begins to breed, cracks appear in the structures. It happens as wood drying. You can avoid such a problem if you work with dry material. The lumber moisture norms are regulated by a number of documents, in particular SNiP II-25-80.

In order to get a high-quality and reliable structure, it is necessary to use during construction only dry wood.

But how to find out the moisture of wood when buying? On the eye it is quite difficult to determine. Only a specialist with extensive experience in some signs can determine wet wood or dry, but it will not give an accurate interest ratio. Some conclusions about humidity can be made when processing lumber. If the chips are removed plastic and bend, then the wood is raw, if it crumbles - dry. The construction standards require accurate figures, and for its definition there are a number of methods that are most used of which are calculated by weight and calculation using a special device - moisture meter.

Calculation of moisture of wood by mass

Figure 1. Table of density of various types of wood.

It is known that various species of trees have different density. But the density depends not only on the breed, but also from the moisture content of the lumber: the land of the wood, the easier it is. Data on the most common breeds are presented in the table in Figure 1. Knowing volume and mass, you can calculate the density, find it in the table for this tree and thus determine the moisture content of the wood. This is a fairly simple and fast way to determine humidity. However, it should be borne in mind that the density of trees of even one breed, but growing in different climatic zones, may vary, so the errors in the calculations will not be avoided.

Article on the topic: Proper reflection of the ceiling in the car

For more accurate determination of lumber humidity, a study is conducted. For testing, a sample is taken in size 20x20x30 mm. The test is cut off from the sawn timber at a distance of at least 30-50 cm from the edge of the board. It is weighed on scales with an accuracy of 0.1 g and is placed in a drying cabinet with a temperature of 101-104 ° C. After 6 hours, the sample is getting out of the cabinet, it is re-weighed and put on the cabinet again. Subsequent weighing are carried out with a frequency of 2 hours. Weighing results are logged. If the difference of the mass on the results of two weighing does not exceed 0.1 g, then the wood is considered absolutely dry.

Calculation of wood moisture.

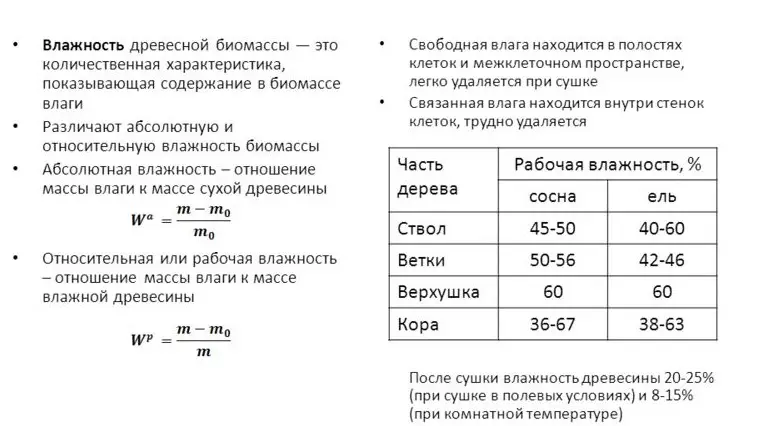

The absolute moisture content of material is calculated by the formula:

W = (M-M0) / M0 × 100 (%),

where W is humidity, M is a sample mass with the first weighing, M0 is the mass of the same sample after complete drying.

It is necessary to consider how to determine the sample humidity on the example. It can be assumed that it weighed 98.76 g drying, after drying - 65.81, then w = (98.76-65.81) / 65,81x100 = 50.1%.

To obtain a reliable result, it is necessary to study with multiple samples. It is not recommended to withstand in the drying cabinet for more than 20 hours samples of resinous rocks.

This method of determining the moisture content of wood corresponds to GOST 16483.7-71, but it takes a lot of time and requires special laboratory equipment.

Determination of humidity with a moisture meter

To determine the moisture content of wood, you can use moisture meter.

Scientific and technical progress, manifested in all spheres of human activity, has not remained aside and with respect to such a question as determining wood moisture. Today, the moisture meter is not surprised. The cost of this portable device depends on the manufacturer, model and set of functions, but it is not as high to abandon this convenient device. The moisture meters are almost any warehouse where lumber are stored or sold. Therefore, the measurement of humidity turns into a minute case.

Article on the topic: Types, ways to decorate windows

The principle of operation of the moisture meter is based on measuring the resistance when the electric current is passed through the wood. The device has needle sensors that are plugged into the sawn timber along the fibers. When you press the measurement button, the current is passed through them, and the result already translated into the humidity indicator is instantly highlighted on the display. Measurement error in modern moisture makers is no more than 1.5%. It should be understood that the result is reliable only for the place where needles are deepened. To judge the status of the sawn timber in general, it is necessary to make as much measurements as possible along the entire length and width of the board.

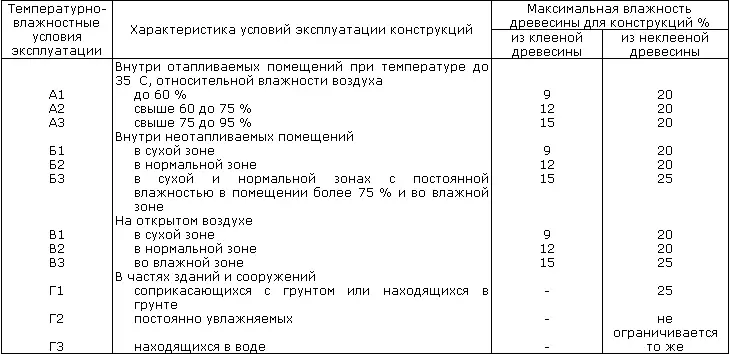

Permissible indicators of humidity of wood according to GOST.

A number of models has a long conductor connecting the device with needle sensors. This allows you to measure the moisture content of wood remotely when it is drying in the chamber. At the same time, the sensors are inserted into the boards located in the middle of the stack. The device itself is placed outside the chamber. When measurements, it is necessary to make a temperature correction. The remote method is convenient to control the wood drying process, but it should be recognized that it often gives distorted results. This is happening for two reasons: due to the heating of the needles of the sensors, which transmit its wood in the places of shut away, and due to the disorders of the dense contact of the sensors due to the drying of the wood.

In cases where it is extremely undesirable to even minimal damage to the wood, for example, if we are talking about the details for furniture, it is possible to determine the moisture content of wood can be a contactless moisture meter. It does not have a needle, but simply applied to the surface of the sawn timber. The principle of action of the device is based on measuring the length of electromagnetic waves, which will differ depending on the humidity. When measuring, such moisture meter should determine the wood in the breed.

Drying wood

Wet wood - not yet a sentence. It can well be brought to a suitable condition even without drying in the chamber. Moreover, atmospheric drying is recommended for any purchased lumber.

Drying wood is reduced to its correct storage. For this, it is equipped with a place on a draft, protected by a canopy of precipitation and direct sunlight. The last condition is due to the fact that under the sun, the surface of the boards is quickly heated and dried, and the lower remains wet. Because of this, voltage occurs, the wood is breached and cracks.

Article on the topic: Installation of LED backlight in the kitchen with their own hands

The stacks are set by lags with a height of at least 0.5 m from the ground level. The base surface must have a strictly horizontal orientation. To avoid the deflection of the boards, the distance between the points of the support should not exceed 1.5 m. Between the rows of boards perpendicular to them are laying boards made of conifers with a thickness of 25-40 mm, and after 1.0-1.5 m - strips thick in 100- 150 mm. This will provide better air circulation. You can not be stored in one headquarters of the boards, having a different moisture: wood hygroscopic, and dry lumber will be wrapped from wet.

The time required for drying to an indicator of 18-22% of moisture varies from 9 to 40 days. It depends on the climatic conditions, the time of year and the thickness of the material.