In country houses, dachas quite often arrange concrete floors on the soil. They are made on the first floors of buildings with a ribbon foundation. Such floors have many advantages: their implementation is inexpensive, they have a simple design, therefore, it is easy to manufacture, durable, reliable.

Laying concrete sex on the soil does not require special qualifications and can be done independently, observing the selected technology, which will significantly reduce the budget.

However, before arranging such floors, you need to make sure that the soil on the stationary, dry, soil waters occur at least 4-5 m. Concrete floors are suitable for heated buildings with basement or basement.

Concrete floors on the ground can be made independently without having special knowledge of the construction business. However, it is necessary to comply with strict technology.

Preparation for floor concreting

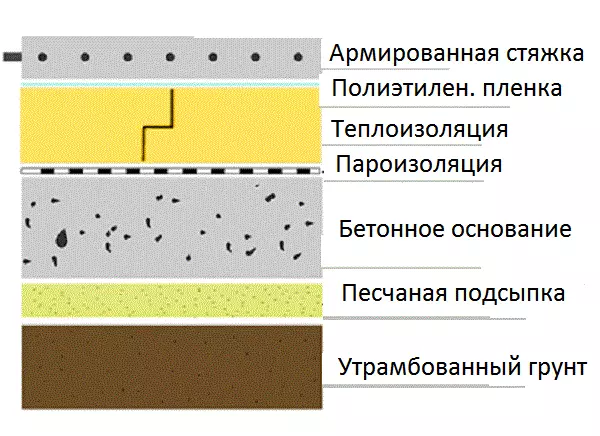

Floor diagram from concrete on the ground.

Materials and tools

- cement, sand, gravel or crushed stone;

- waterproofing and thermal insulation material;

- Armature;

- Scotch;

- lighthouses;

- concrete mixer;

- vibratinglitis;

- rule;

- level;

- shovels;

- jackhammer.

The whole process of concreting includes several steps:

- performing flooring markup;

- Preparation of soil;

- Laying sand-gravel pillows;

- Laying the waterproofing and thermal insulation layer;

- reinforcement;

- Installation of guides;

- making formwork;

- fill;

- Floor screed.

Concretion is performed using cement, sand and rubble. To calculate the required amount of materials, you need to multiply the area of the room on the thickness of each layer of the structure. The solution is prepared, observing the following proportions: 1 - cement, 2-sweep, 3 - rubble.

If you use a purchased mixture, then by 1 part of the cement it is necessary to take 6 parts of a 20-millimeter rubble with sand. The screed is performed with respect for the ratio: 3 parts of sand and 1 - cement.

To prepare a large volume of concrete it is more convenient to use a concrete mixer. First, fill the mixer for two thirds in the ingredients, without adding water, observing the necessary relationships. The ingredients are thoroughly mixed, then water is added before the formation of a homogeneous consistency. In the future, the mixture must be prepared by pouring the water first. After concreting, the unit must be rinsed thoroughly.

Article on the topic: how to make a crate on the loggia and the balcony

Filling floor: The main stages

Floor circuit on soil with insulation.Before starting work, rent a room on the sectors of a width of 1 m. The floor is desirable to begin with a portion distant from the door. With proper concrete, care is not required. If the old screed crackled or need to run the laying of a new one on top of the old, cracked the surface is broken with a jackhammer.

The first step in the manufacture of concrete floor is the performance of the markup, the determination of the zero level on the bottom of the door, which is then denoted by the perimeter of the room. It is before this line will need to pour concrete. To freely navigate, score nails in the corners and pull the cord. Next, you need to prepare and rapt the soil. Removing all litter, remove the top layer of the Earth.

Since the design of the floor looks like a puff pastry with a thickness of 30-35 cm, the soil is removed until the overall height of the zero level is equal to the thickness of the cake. Perform a thumbtail with vibrating plastic. If it is not, take the log, make a handle on top, and at the bottom - the board. It is necessary to achieve perfectly even and strong foundation.

In order to improve the waterproofing properties, put clay, and then sand. Sweep clay with water and well compact, it will not give the surrounding soil waters. After executing these works, it is necessary to lay gravel with a thickness of 5-10 cm. Slash it and compact. Then put the sand with a thickness of 10 cm. Put the crushed stone of the fraction of 40-50 mm. Sealing the resulting layer, put a little sand and scatter. All layers of design need to withdraw the horizon. Therefore, at each stage, the level is used.

Waterproofing and heat insulation

For waterproofing, polyethylene is used with a thickness of 200 md. When laying the edge, output slightly above the zero level. The sheets of the film are stacked, the joints of the joints glue the scotch.

Article on the topic: Types of rubber flooring

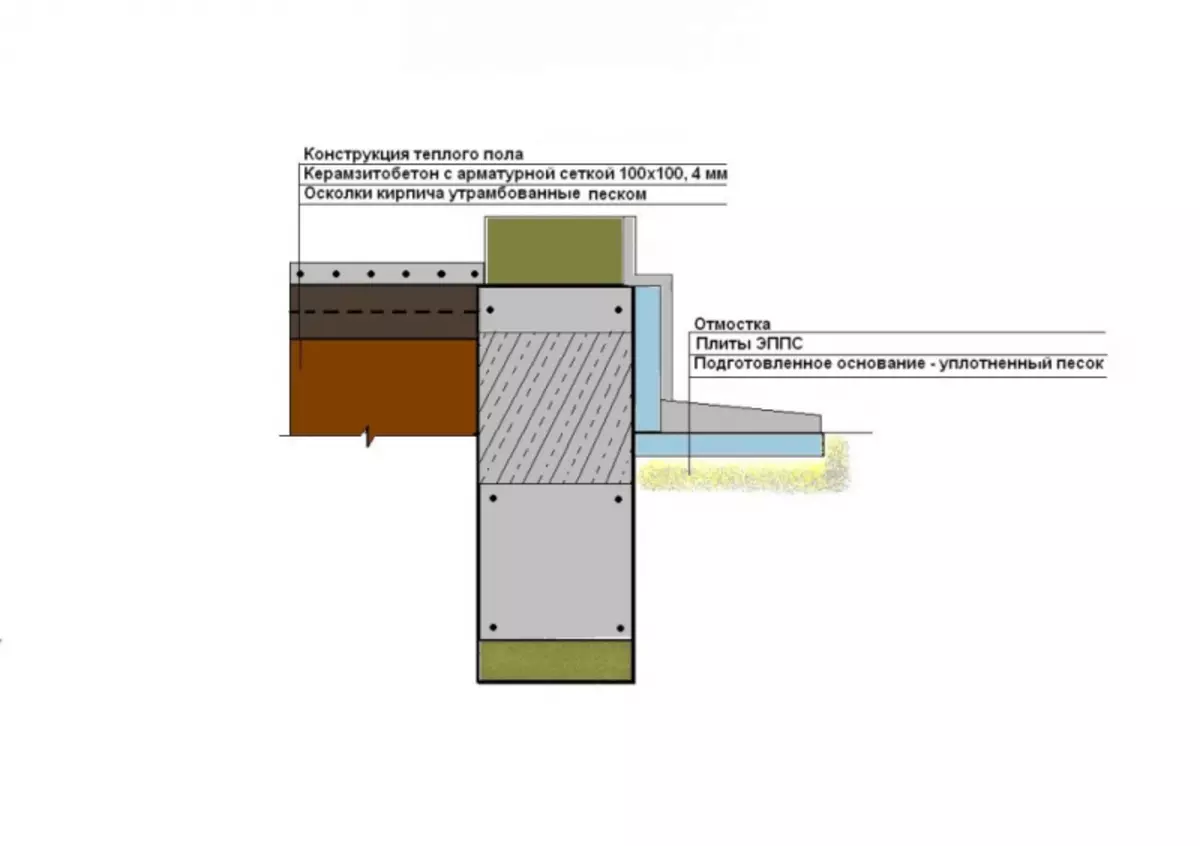

Concrete floor diagram for soil with ceramisite insulation.

As thermal insulation, materials such as polystyrene foam, crumples, basalt and mineral wool and others can be used.

After that, proceed to reinforcement. It is performed using a plastic or metal mesh, reinforcement. The frame must be a height of 2-3 cm in the presence of tools and skills you can perform welding frame.

Experts are recommended to perform styling guides that are usually made from the board or bar. The room should be divided into smooth segments, their width can be a maximum of 2 m. Please note that the height of the guides should coincide with the zero level. The first parts are fixed with a sandy cement mixture with the addition of clay. Between the guides make formwork. A kind of "cards" are formed, which are then poured with concrete, it makes it much easier to fill the floor. The design makes most often from waterproof plywood. In the manufacture of formwork and installing guides, do not forget to check the horizontality using the level to achieve a smooth fill of the floor. You can easily pull the guides and formwork from concrete if you treat them with oil.

Filling the Pole

Filling the floor is performed for 1 or 2 approaches. So it turns out a reliable monolithic design.

To prepare the mixture, mix the components in the following proportions: 1 part of cement M 400-500, 2 - sand, 4 - rubble and 0.5 parts of water. Concrete flooded floor. You need to start from the corner distant from the doorway. Bay a couple of "cards", shovel distribute the mixture. To get a dense shrinkage, use the vibrator. It will also help remove the resulting air bubbles.

When performing a draft alignment, a 2-meter rule put on guides and attract to themselves. So the extra concrete is removed and empty "cards" are filled. In areas where the screed has been taken, formwork and guides are removed. Empty space is poured concrete. When in the same way, you align the entire area of the room, cover the floor with a plastic film and leave for 3-4 weeks. The design must harden. At this time, the floor must be periodically wetted.

Article on the topic: Self-adhesive wallpaper: Adhesive for walls and furniture, film adhesive for the kitchen, photo, how to glue, is it possible to film on wallpaper, video, under a brick, how to remove from the wall

The final concreting step is a screed of a self-leveling mixture. This will help to remove small irregularities, forming an absolutely smooth surface. You should also perform work from a remote corner from the door of the room. The mixture is applied by the rule and stretch over the entire surface. Leave it for 3 days.

The final stage will be the installation of an outdoor coating. With proper manufacture, the concrete floor will serve not one decade, the underlying condition is the observance of the process of filling concrete.