Ukukhiqizwa kokhonkolo wegwebu ekhaya

Ukwakhiwa komuntu ngamunye kuyalulekwa esimweni senani elikhulu lomsebenzi.

Lapho-ke izindleko zemishini yokuthenga iyakhokha ngokuphelele. Kepha, kukhona indlela okwamanje

Inqubo yokukhiqiza eshibhile - yenza imishini yokukhiqiza

Amabhulokhi Foam Wenze ngokwakho.

Cabanga ngezinketho ezicacisiwe ngokungaguquki ngesimo se

Isinyathelo ngesinyathelo imiyalo yabaqalayo ngaphandle kokuhlangenwe nakho ekwakhiweni.

1 Inketho - Ukukhiqizwa kokhonkolo kwe-mini foam ngezandla zawo nge

Kusetshenziswa imishini eseqediweUkukhiqizwa kwamabhulokhi wegwebu ekhaya

Ukufakwa kuthengwa - Isakhiwo semishini ekhethekile (umshini), futhi

Ingxube kakhonkolo kaFoam ilungiselelwe ngokuzimela.

Ukwakheka kwengxube ye-foam:

- Usimende (usimende wePortland, m-400 brand nangaphezulu. Usimende kufanele

ube musha ngokweqiniso) - 310 kg;

- Isihlabathi (isihlabathi esihle noma esichotshoziwe, esingcwele) -

500 kg;

- amanzi - 210 l;

- Ukwakheka kwe-fooming kungu-1-2% wesisindo sikasimende;

- Ukuguqula izengezo.

Ngokwehlukana, gxila kumenzeli we-Foaming. Ingasetshenziswa

Ukwakheka okulungele, ngokwesibonelo, i-PB Luxury (ama-ruble angama-90 / kg) noma i-Foamcem (ama-ruble angu-150 / kg) noma

Zenzele ngokwakho.

Umenzeli we-Foaming ngokhonkolo wegwebu

Ukwakheka kwe-ejenti ye-Foaming:

- I-Caustic Soda (Caustic Soda) - 0,15 kg;

- rosin - 1 kg;

- I-Colue Glue - 0.06 kg.

isikhathi esiningi. Ngakho-ke, kufanelekile kuphela ngamanani aphezulu omsebenzi.

Ungawenza kanjani umenzeli we-Foam ngokhonkolo wegwebu ekhaya

Ukulungiselela kubandakanya ukwenza izigaba ezimbili:

- Ukuxuba isixazululo esinamathela. Kulezi zincucu zeglue esomile

Gcwalisa ngamanzi (1: 10) bese ushiya usuku. Ngalesi sikhathi glue kancane

Vuka, kepha uzoqhubeka ukwakheka. Ngakho-ke, ithangi lamanzi ne-glue kufudumele

Kufika ku-60 ° C (ngokuvusa okungapheli). Isixazululo se-glue silungile lapho konke

Izingcezu zancibilika futhi zakha isisindo esinobunzima;

- Ukulungiselela insipho ye-rosin. Ngale njongo, i-Natra yalethwe

ukubilisa. Lapho-ke i-rosin yangeniswa kancane kancane kuwo. Inqubo ebilayo izohlala

Cishe amahora ama-2 ngaphambi kokuchithwa okuphelele kwe-rosin.

Qaphela. I-Rosin kufanele ichotshozwe.

Zombili lezi zingoma zihlanganiswa lapho insipho ye-rosin iphola kuze kufike ku-60 ° C.

Qaphela. Lapho kuxuba, insipho ye-rosin ithululelwa kuyo

Isixazululo se-glue. Isilinganiso sokuxuba 1: 6.

Isihloko ngesihloko: ikhebula le-ASB: Ukuhlolisisa, ukucaciswa

Ingxube evelayo ithululelwa e-forder fogerator futhi yathola i-foam

Ubuningi obuphezulu. Ukusetshenziswa kahle kubhekwa njenge-foan density 80

GR / DMKUB. Sebenzisa okuncane okuncane (amagwebu amaningi e-air) ikhwalithi embi kakhulu

Vimba futhi kuzoholela ekubhujisweni kwayo okusheshayo.

Qaphela. Bheka ikhwalithi yegwebu, ungaligcwalisa

ibhakede. Ngemuva kokuguqula ibhakede, igwebu kufanele ligcinwe ngaphakathi.

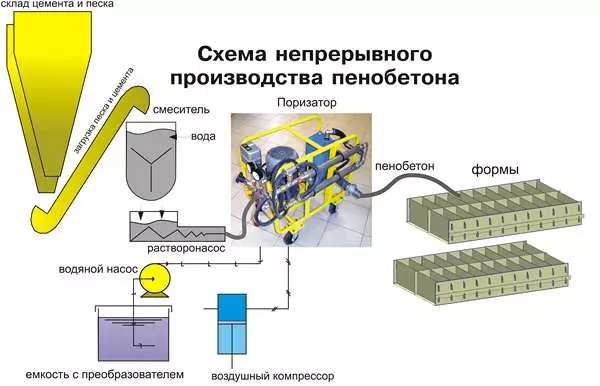

Isikimu sokukhiqiza i-Foam block sikhonjiswa esithombeni.

Isikimu sokukhiqiza se-Foam block

Qaphela ukuthi njenge-pancake yokuqala, ukhonkolo wokuqala wegwebu

Amabhlogo ajwayele ukuphuma. Kunezizathu eziningana zalokhu:

- ubunzima bezakhi ze-dosing kwikhambi;

- okuqukethwe okwengeziwe / okuncishisiwe kwamanzi ngesixazululo;

- Ukwanda okuqukethwe kwe-ejenti ye-foaming kusixazululo. Yena

Ukusetshenziswa akufanele kudlule amalitha ayi-1.5. ngemitha eyi-1 m / cubic.

Okokuqala, ngoba umenzeli we-Foaming uyabiza.

Okwesibili, ngoba ukwanda kwengxube yalo

Kwandisa isikhathi sokuqina kokhonkolo.

Okwesithathu, ngoba kuzonciphisa amandla ebhlokhi.

- isikhathi esishintshayo uveze;

- Ukuchazwa kwesikhathi sokuqina kokuqina

amabhlogo;

- Imodi yomawomi isilungele (iboshwe) amabhlokhi.

Ngeshwa, izivivinyo ezinjalo aziveli kuphela

Isikhathi sokwakha, kepha kuholele ezindlekweni ezengeziwe. Kodwa-ke, njengoba

Bafakazele abasebenzisi, banengqondo ngokuphelele. Ikakhulukazi kusukela kunephutha

Amabhulokhi we-Foam angasetshenziswa njenge-bacfill ngaphansi phansi, futhi asetshenzisiwe

Okokusebenza kokukhiqizwa kokhonkolo wegwebu kungathengiswa.

Qaphela. Njengombukiso wokuzijwayeza, kungcono ukukwenza

Amabhulokhi we-Foam ehlelekile (ama-brand d-900 nangaphezulu). Ziqukethe ama-pores amancane

Uma kuqhathaniswa nokufakelwa okushisayo, kanye nabaqalayo ukubenza kube lula.

2 Inketho - Yokwa Kwemishini ye-Foam ukhonkolo ngezandla zawo

Ukuqala, siyabona ukuthi yiziphi izinsizakusebenza ezidingwayo

Ukukhiqizwa kwamabhulokhi wegwebu lapho usebenzisa ubuchwepheshe besigaba esisezingeni eliphakeme

ukukhiqiza.

Ukuhlelwa kwefektri kwesitshalo esincane sokukhiqizwa kokhonkolo wegwebu kufaka phakathi:

- I-Foam generator ene-air Supply compressor;

- I-Mixer (Ukukhiqizwa Kwangasese Kusetshenziswa Ngokujwayelekile

u-concrete mixer);

- Amafomu amabhlokhi wegwebu;

- Eminye imishini: I-Pressure Gauge, Pump.

Imishini yokufakwa kokhonkolo okujwayelekile kwe-foam kukhonjiswa kuyo

Uhlelo.

Cabanga ukuthi ungasenza kanjani inhlobo ngayinye yezinhlobo ezifakwe ekhaya ekhaya kusuka ezindleleni ezihanjisiwe.

I-Foam generator ye-foam ukhonkolo

Ukutholwa kwale module kuyingxenye ebiza kakhulu.ukukhiqiza.

Inhloso - Guqula i-foam foam ngaphambili

ukuzondla ngesisombululo.

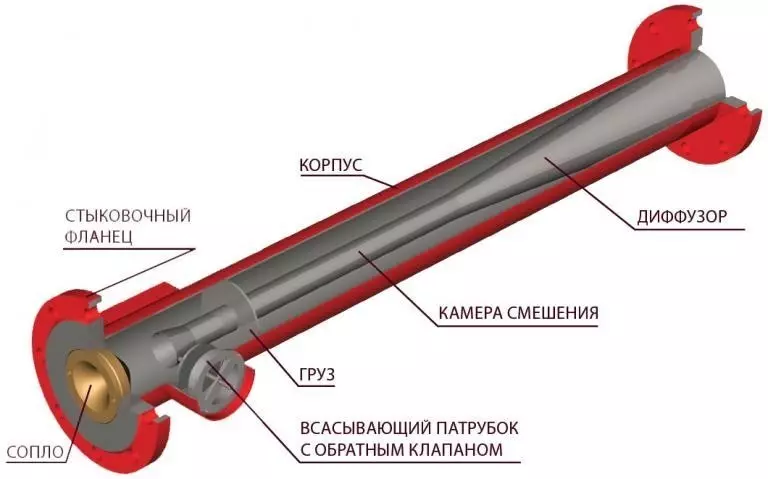

Idizayini ye-Foam Generator iqukethe izindawo ezintathu:

- Module okondlayo. Isixazululo somenzeli we-Foaming sithululelwa kuwo.

Lesi sici singenza noma yisiphi umthamo;

- Ukuguqula imodyuli. Ukufakwa kwe-Kintessenti - Ukuguqulwa

Foam;

- Imodyuli ye-dosing. Ihlinzeka ngamathuba okugcwalisa igwebu ngaphakathi

Isixazululo sobukhulu obunikezwe (esinqunywe ngumkhiqizo we-foam block).

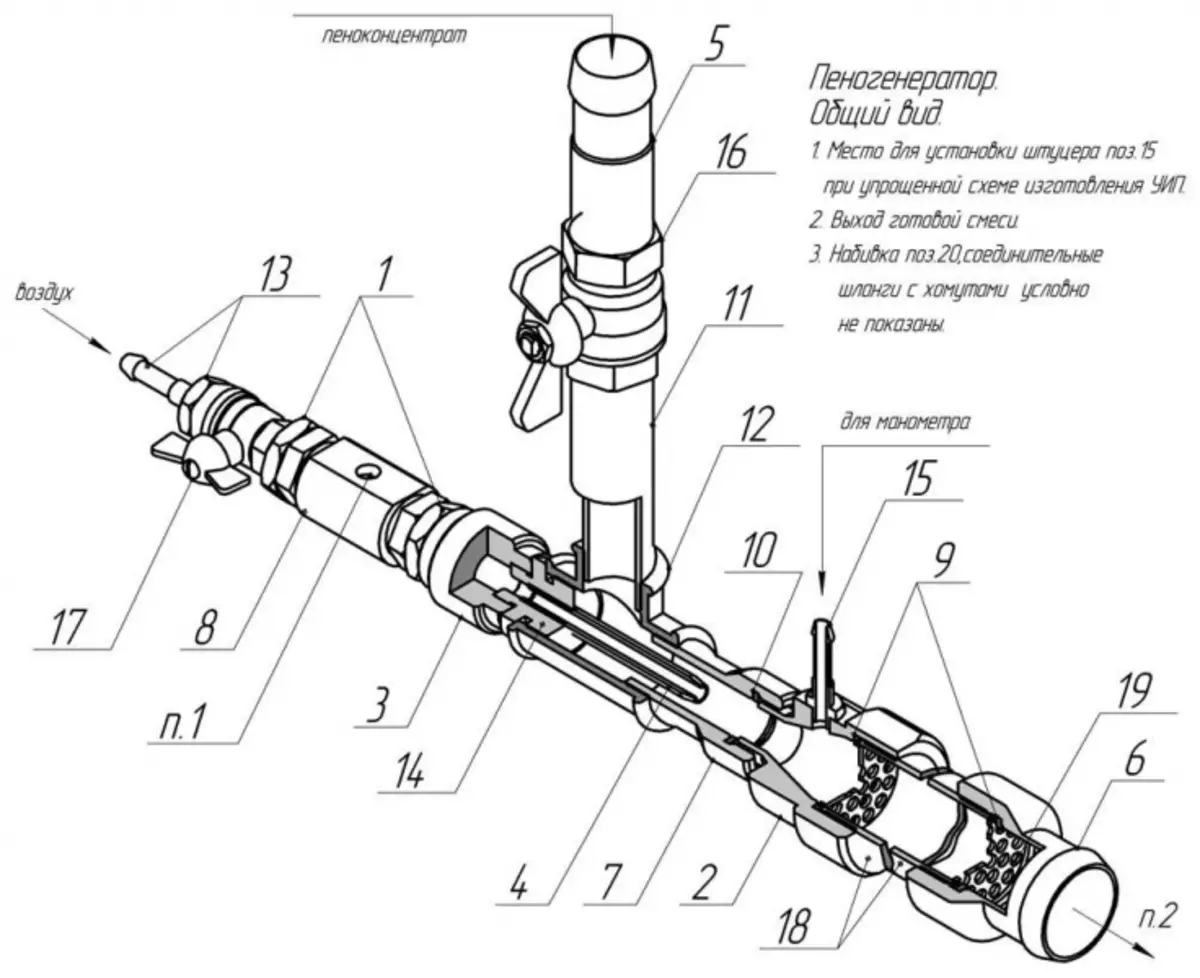

Uhlelo lwe-penogenator lokukhiqizwa kokhonkolo wegwebu

Isikimu Sedivayisi ye-Foam ye-Foam ukhonkolo ukukhiqiza

Ngokwenziwa kwe-Foam Generator, uzodinga: Metal

Ipayipi (2 izikhala), ipompo, ama-hoses, ama-valve. Kanye nomshini we-welding. Okuningi

Ngezingxenye zemininingwane zichaziwe ekucacisweni okuhambisana nomdwebo

I-ponogenator.

Ukuhlangana i-ejenti ye-foam ngokhonkolo we-foam (umdwebo womdwebo)

I-Footage ngokhonkolo wegwebu

1. Ukukhiqizwa kwe-Foam Generator

Ukucaciswa kwe-tube yefektri ye-foorgerator ye-foam ukuthi ekuqaleniInomsele omncane, oyakhula ngaleso sikhathi. Le ndlela ivumela

Khulisa ijubane le-tube emulsion. Ngemuva kwalokho uzoba nakho

Isivinini esikhulu esinokwenzeka.

Isihloko ngesihloko: Ama-jumpers azenzele ngokwakho

Ungayenza kanjani i-foam generator ye-foam ukhonkolo?

Ukuze wenze lokhu, yenza iChamber edidayo yokuxubha futhi

I-ponocentron eyisisekelo.

Ukwenza igumbi lokuxuba

Kwelinye lamapayipi avuniwe ukuze ashiye ama-nozzles amabili. Chitha kwalokhoOmunye wabo (lapho kuzonikezwa khona umoya) Kungcono ukubeka

qeda. Kanti okwesibili, eklanyelwe ukondla i-emulsion ye-fooming ukwamukela

ohlangothini (e-angle ka-90 °).

Bobabili i-inlet nozzles (ukuphela kanye ohlangothini) kufakwe amabili

Ama-Valve:

- ukukhiya (okuvumela ukunqamula okuphakelayo kwe-ejenti ye-Foaming);

- Ukulungisa (ukuvumela ukuthi uguqule amapharamitha okuphakelayo,

Shintsha ingcindezi, ingcindezi, ubungako, njll.).

Ekusebenzeni, ngemuva kokuthi amapharamitha okuphakelayo ayalungiswa

Ukuxuba, ukuguqula ama-valves awasebenzisi.

Qaphela. Ububanzi be-nozzle eseceleni kumele kube ngu-15-20%

Ububanzi obuningi bokuphela kwe-nozzle.

Ukukhiqizwa kwePonopathron

Ipayipi lifakwa kwisikhungo sesibili sokusebenza. Yona

Yakhelwe ukuphuma ingxube eseqedile. Okuphumayo kwe-nozzle

Okokusebenza esimweni sendlela ye-funnel ukunciphisa ijubane lengxube.

Isihlungi sibekwe endaweni yokusebenza. Inhloso yalokho, ukuguqulwa kwe-emulsion ku

Foam. Ungathenga isihlungi esiqediwe.

Kepha ukusebenza kwayo ngaphandle kwempumelelo engaphansi

Imiyalezo yensimbi (izinduku) zokuhlanza izitsha.

Ngasikhathi sinye, imiklamo ayifanele, kuphela ucingo. Lezi

I-mesh kufanele ihlatshwe amandla eduze ngangokunokwenzeka kulo lonke ubude bepayipi le-polypaththron.

Ukuze izinhlayiya zegridi zingandizene ndawonye nengxube yokukhipha ipayipi

Kufakiwe "Ers", ngaphakathi i-washer ye-mesh efakiwe.

Ikhamera yokuxuba nepensela

Okulandelayo, udinga ukuxhuma igumbi lokuxuba ne-pennipotron.

Ngokwemvelo, kuyadingeka ukukwenza ukuze ama-nozzles afakwe ama-welded abekwe nawo

okuphambene nalokho. Ukuqinisekisa ukwanda kwesivinini sokudlula

Ingxube kakhonkolo kakhonkolo ku-tube, udinga ukufaka i-nozzle ye-boiler phakathi kwabo noma

Washer boiler. Ukubuyisela esikhundleni se-nozzle kuJoboker kuzonciphisa ukusebenza kahle kwe-30-40%, ngenxa

Ukunciphisa ijubane lokudlula le ngxube ngalo. Kodwa-ke, kushibhile, kulula ukukufaka

futhi ingasetshenziswa njengenketho yesikhashana. Beka ukufaka i-nozzle noma i-gibler

Ekhombisa uhlelo.

I-Penogen Footage Scheme ye-Foam ukhonkolo usebenzisa i-sauer-gibler

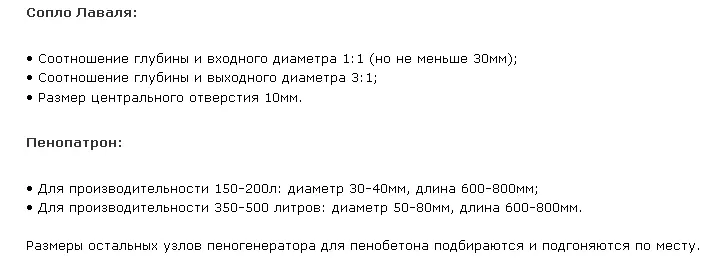

Isilinganiso sosayizi we-foam generator for Foam ukhonkolo (ukujula kanye nobubanzi be-inlet)

Isilinganiso sosayizi we-foam generator ngokhonkolo wegwebu

2. Ukuxhuma i-compressor kwisixhumi sokugcina segumbi lokuxuba

Noma yimuphi umcindezeli ulungele umsebenzi, ozohlinzekaIngcindezi ku-6 ATM. Sebenzisa i-compressor nge-receiver, i-valve yokunciphisa

Futhi igeji yokucindezela izovumela ukuqondisa ingcindezi.

Izinto ezilungiselelwe isayithi www.moydomik.net

3. Ukuxhuma isitsha se-ejenti ye-Foaming ohlangothini

Hlanganisa ipayipi lekhamera

Isitsha sifakwe phansi, i-hose inamathele kuyo,

nge-emulsion ye-fooming (i-agent e-agent enamandla) izokwenza

FUNDA KAKHULU NGOKUXHUMANA NGOKUQHAZA NGOKUGCINA. Ukufaka

Iphampu elincane (umsakazo ojwayelekile "wasendlini") kuzovumela ukuhlela okwengeziwe

Amagwebu asebenzayo ku-fogerator ye-foam. Kodwa-ke, ukuze ulondoloze

Okuphakelayo kungahleleka kanye namandla adonsela phansi.

Isihloko ngesihloko: Ungathunga kanjani amakhethini amadala egumbini lokuhlala ngezandla zakho

Umenzeli we-Foaming owenziwe ngokungalingani

Ukhonkolo wegwebu luzobiza kakhulu kushibhile kunokuthengwa. Futhi i-foam ephumele lutho

Ngeke anikeze i-foam etholwe efektri yefektri.

Imishini eyenziwe ekhaya yokukhiqizwa kwamabhulokhi we-foam - ividiyo

Idivaysi ye-foam generator ye-foam ukhonkolo ekhayaIngxenye yesibili yokukhiqizwa kwamabhulokhi wegwebu, ongakwazi

Ukwenza okwakho kuyindlela yokugcwalisa ukhonkolo we-foam.

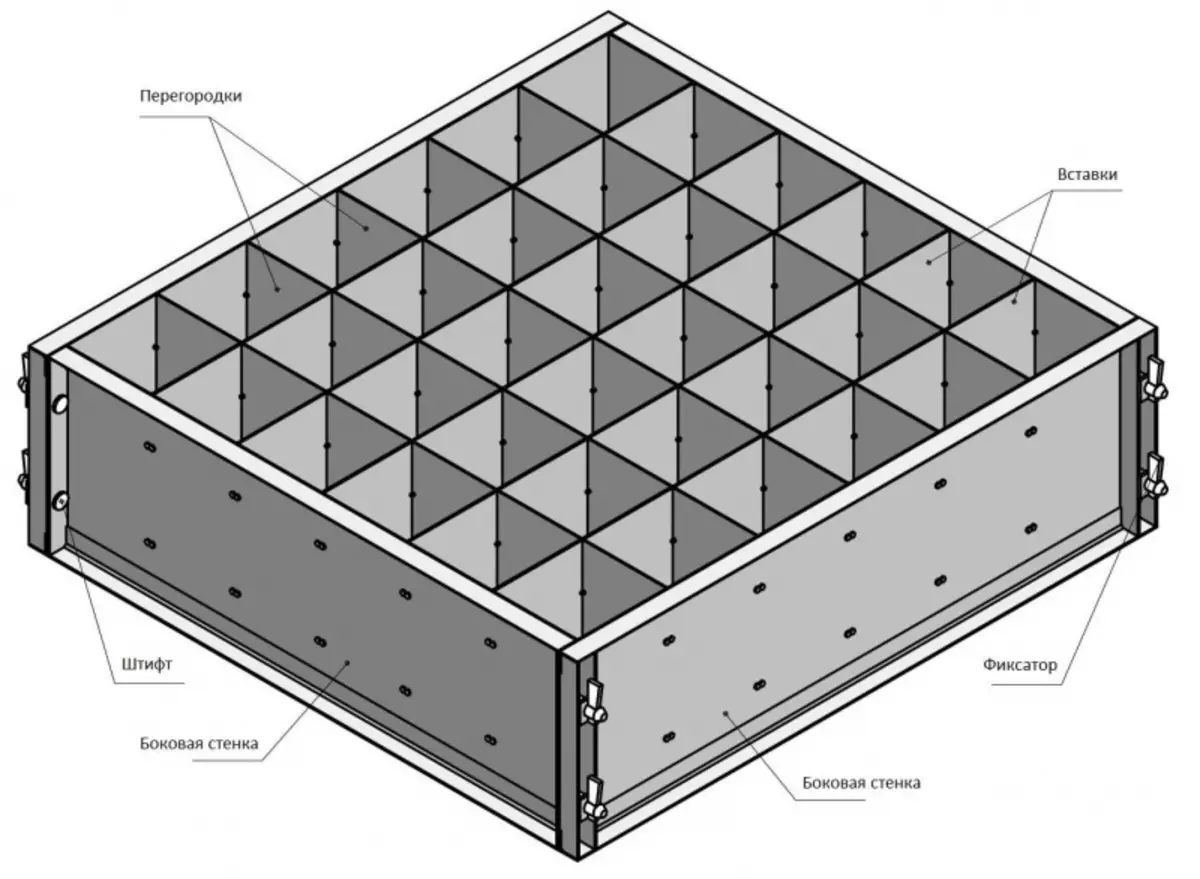

I-FOCKS yamabhulokhi we-Foam Wenze ngokwakho

Amandla okubumba angenziwa nganoma iyiphi

Izinto ezibonakalayo: Plywood, Metal, Plastic. Isidingo esikhulu, impahla akufanele

Deform in inqubo yokugcwalisa ikhambi.

Ukwenza ifomu kufaka phakathi ukudlula kwezigaba ezimbili:

- Amafomu okubala ngokhonkolo wegwebu;

- Ukukhiqizwa kwesimo sikakhonkolo wegwebu.

Ungabala kanjani kahle usayizi wefomu le-Foam block?

Amabhlogo wokwakha (izindonga) avame ukukhiqizwa kulokhuisilinganiso (isilinganiso) ubude: Ububanzi: Ukuphakama - 4: 2: 1. Isilinganiso esinjalo

ilungile ngoba ivumela ukusatshalaliswa komugqa wama-masonry ngaphandle

Amabhlogo we-trim. Ngakho-ke, uma ukujula kwefomu kungu-150 mm, khona-ke ububanzi bawo nobude bawo

Kuzoba ngu-300 no-600 mm, ngokulandelana.

Ngokukhiqizwa kwangasese kwamabhulokhi kakhonkolo, kuyalulekwa

Sebenzisa ifomu elikuvumela ukuthi wenze ngasikhathi sinye emabhulokini angama-30 we-foam.

Qaphela, ubude obude buzoba bude kunengqikithi

Amabhlogo ubude. Lokhu kungenxa yokuthi izihlukaniso ezisefomini zinokuthile

Ubukhulu.

Qaphela. Kungcono ukufaka izihlukaniso ngendlela enjalo

Ukuze indiza yendawo enkulu kakhulu ingaphezulu. Ngale ndlela,

Ihlinzeka ngokuvinjwa okusheshayo kwebhulokhi kanye nesethi eyunifomu yamandla

Ukhonkolo wegwebu. Ngesizathu esifanayo, akunconywa ukwenza amafomu aphezulu.

Ungazenza kanjani amabhlokhi amagwebu ngezandla zakho?

Inqubo yokwenza ifomu liqale ngedivayisi engezansi. Kwa-

Akunakunamathiswa izindonga eziseceleni ezingenakuvalwa futhi ziyancipha ngaphakathi

Ukwahlukaniswa.

Amakhosi akweluleka ukwenza ifomu lamabhulokhi kakhonkolo wegwebu

kuyawa. Le ndlela izokwehluka ngosayizi wamabhulokhi. Ngesizathu esifanayo

Amapuleti ahlukanisayo akufanele afakwe. Kungcono ukwenza kuzo

Inquma kuze kube yingxenye yobubanzi futhi ihlanganise ngayo.

Uma i-plywood isetshenziswa njengento ebonakalayo ye

Ukwenza amafomu, khona-ke udinga ukulungisa izingxenye ezinezinzipho. Amakhona, ama-struts futhi

T.p. Ephrintiwe ebhlokini eliqediwe. Ngeke imlimaze, kepha futhi nobuhle abukho

Enezelela

UMkhandlu. Kungcono ukusebenzisa i-lamiated waaeae.

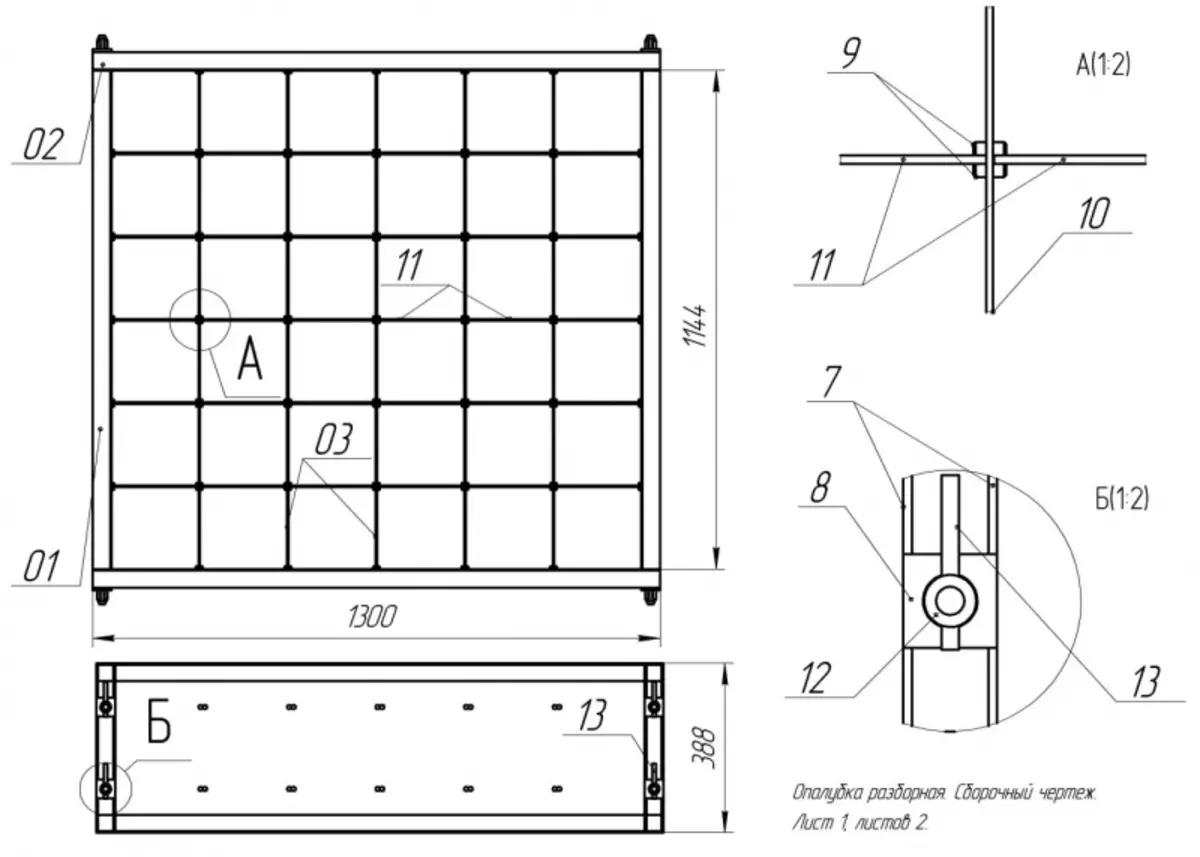

Umdwebo-umdwebo wefomu lamabhulokhi we-foam nokubukeka kukhonjiswa ku

imidwebo.

Umdwebo womndeni womndeni

Umdwebo weSikimu wefomu lamabhulokhi we-foam (osayizi bezinto zokwakha amafomu)

I-Metal Formwork (ukwakheka) kokukhiqizwa kwamabhulokhi wegwebu

Amafomu E-COMS EBUCHWEPHESHE WOKUGCINA IZIMBALI

Inzuzo yefomu elenzelwe wena kungenzeka

ukuthola amabhlogo we-foam ubude noma ukucushwa okujwayelekile noma ukucushwa.

Qaphela. Lapho wenza uhlobo lweplywood, ngaphambi kokugcwalisa

Kumele kuqiniswe ngefilimu eqinile. Ngaphandle kwalokho, i-plywood edonsa

Umswakama ovela kusisombululo esivuthiwe, esizofaka ukonakala kwesimo nokuhlanekezela

Izici zikakhonkolo wegwebu. Kusetshenziswa ifilimu kube lula inqubo

Amabhlokhi akhanyayo.