Ingcindezi engapheli ohlelweni lokuhlinzekwa kwamanzi lwendlu yangasese ivame ukwenziwa kusetshenziswa isiteshi sokupompa. Kuyacaca ukuthi kungcono uma kusebenza ngaphandle kwezinkinga, kepha ukwehlukana kwenzeka ngezikhathi ezithile. Ukubuyisela ngokushesha ukulethwa kwamanzi bese ugcine ezinsizakalweni, ungalungisa isiteshi sokupompa ngezandla zakho. Iningi lokuqhekeka lingaqedwa kokwabo - akukho okubhekwa ukukwenza.

Ukwakheka kwesiteshi sokupompa nezinhloso zezingxenye

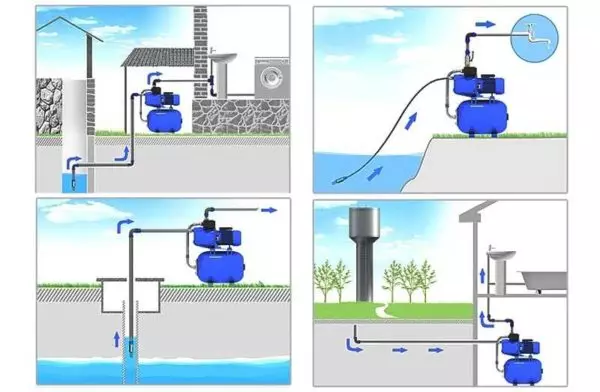

Isiteshi sokupompa sisethi yamadivayisi ahlukile axhunyiwe. Ukuze uqonde ukuthi ungalungisa kanjani isiteshi sokupompa, kufanele wazi ukuthi liqukethe lokho, ukuthi izingxenye ngayinye zisebenza kanjani. Lapho-ke amaphutha aqeda lula. Ukwakheka kwesiteshi sokupompa:

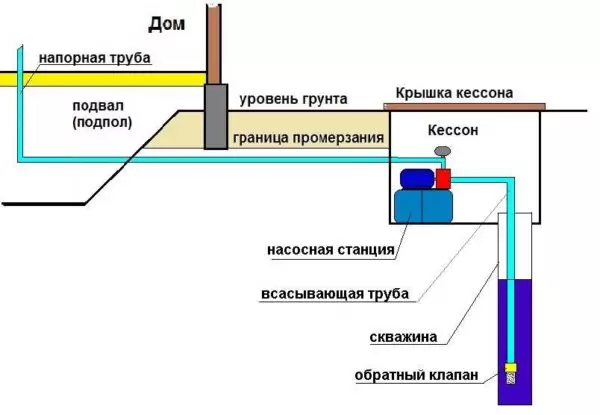

- I-subsible noma i-survate uhlobo pump. Shintsha amanzi emthonjeni noma kahle, ugcina ingcindezi ezinzile ohlelweni. Indlu ixhunyiwe ngosizo lwamapayipi.

- Ku-pipeline kuyadingeka ukufaka i-valve yesheke. Ayinikezi amanzi lapho iphampu inqanyulwa kumapayipi abuyele emthonjeni noma kahle. Kuvame ukufakwa ekugcineni kwepayipi, kwehliswe emanzini.

Yini isiteshi sokupompa

- I-Hydroaccumular noma ithangi le-membrane. Isitsha sensimbi hermetic, sahlukaniswa ngama-halves amabili kalwelwesi oluningi. Kokunye, umoya (igesi e-inert) ungaphansi kwengcindezi, komunye, ngaphambi kokudala ingcindezi ethile, amaphunga amanzi aphuma. I-hydroaccumulator iyadingeka ukunciphisa inani le-inclusions yepompo, ukunweba impilo yayo yenkonzo. Kwakha futhi kugcina ingcindezi edingekayo ohlelweni kanye nokuhlinzekwa kwamanzi okuncane uma kungalinganiswa kwesiteshi.

- Iyunithi yokulawula nokulawula isiteshi sokupompa. Lokhu kuvame ukuba yi-gauge yengcindezi nokushintsha kwengcindezi, kufakwa phakathi kwephampu kanye ne-hydroaccumulator. I-Manometer iyisilawuli esikuvumela ukuthi ulinganise ingcindezi ohlelweni. Ukushintshwa kwengcindezi kulawula ukusebenza kwephampu - kunikeza umyalo wokuvula nokucisha. Ukufakwa kwephampu kwenzeka lapho umkhawulo wengcindezelo ephansi ufinyelelwa ohlelweni (imvamisa 1-1.6 ATM), ukuvala i-ATM, izakhiwo ezingenhla zifinyelelwa (ngezakhiwo ezihlala zingama-26).

Isitho ngasinye sibhekele ipharamitha ethile, kepha uhlobo lwephutha elilodwa lungabangelwa ukwehluleka kwamadivayisi ahlukahlukene.

Isimiso sokusebenza kwesiteshi sokupompa

Manje ake sibheke ukuthi wonke la madivayisi asebenza kanjani. Uma uqala ukuqala uhlelo, ipompo iphonswe kumanzi we-hydroaccumularator kulawo abonakele kuze kube yilapho ingcindezi kuyo (futhi ohlelweni) ilingana nomkhawulo ongenhla ekudluliseleni ngengcindezi. Akukho ukusetshenziswa kwamanzi okwamanje, ingcindezi iyazinza, iphampu icishiwe.

Ngayinye yalezi zingxenye yenza umsebenzi wayo.

Enye indawo bavula i-crane, amanzi ancishiswa, njll. Okwesikhashana, amanzi avela ku-hydroaccumulator. Lapho inombolo yayo inciphisa kakhulu kangangokuba ingcindezi e-hydroaccumulator yehla ngaphansi komkhawulo, ukushintshwa kwengcindezi kudalwa futhi kufaka phakathi iphampu epompa amanzi futhi. Kuvala futhi ingcindezi edluliselwe emuva lapho umkhawulo ongenhla efinyelelwa - umkhawulo wohambo.

Uma kukhona ukusetshenziswa kwamanzi okuhlala njalo (okugeza, ukuthambisa ingadi / ingadi kuvuliwe) amaphampu okugijimisa isikhathi eside: ngenkathi ingcindezi oyifunayo ingenziwanga ku-hydroaccumulalator. Lokhu ngezikhathi kwenzeka ngisho nangawo wonke ama-cranes avulwe, ngoba iphampu inika amanzi ngaphansi kwayo okulandelayo kuwo wonke amaphuzu wokuhlanza. Ngemuva kokuthi ukusetshenziswa kwamenyezelwa, isiteshi sisebenzela isikhashana, sakha indawo egciniwe e-Gyroaccumulator, khona-ke iyacima bese iphenduka ngemuva kokuphinda amanzi.

Izinkinga nokungasebenzi kweziteshi zokupompa kanye nokulungiswa kwazo

Zonke iziteshi zokupompa ziqukethe izingxenye ezifanayo futhi ukwehlukana kwazo kujwayelekile. Akukho mehluko, imishini yi-Grundfos, Jumbo, i-alco noma amanye amafemu. Izifo nokwelashwa kwazo kuyafana. Umehluko ukuthi la maphutha avame kangakanani ukwenzeka, kepha uhlu lwazo nezimbangela zivame ukufana.

Izinketho Zokupompa zesiteshi sokupompa

Isiteshi sokupompa asicishiwe (akukho cindezelo ekudayela)

Kwesinye isikhathi uyabona ukuthi ipompo isebenza isikhathi eside futhi ngeke icime. Uma ubheka igeji yengcindezi, kungabonakala ukuthi isiteshi sokupompa sikuthola ingcindezi. Kulokhu, ukulungiswa kwesiteshi sokupompa kuyibhizinisi lesikhathi eside - kufanele unganaki inani elikhulu lezizathu:

- Emthonjeni noma kahle akukho manzi . Uma lokhu kuyiqiniso, ibizwa ngokuthi isimo esinjalo esithi "ukugijima owomile" futhi kusongela iqiniso lokuthi imoto izokhula. Amanzi amaphampu amaphampu asetshenziselwa ukupholisa imoto. Awekho amanzi, awela ngokweqile futhi ashise. Ukuvikela esimweni esinjalo, kudingeka ukuvikelwa okukhethekile: izinzwa zezinga lamanzi (ukuntanta kanye nogesi).

- Ukumelana okukhulu komgwaqo omkhulu wokumunca (ubude obukhulu obunobubanzi obuncane bamapayipi) noma izihlalo zomoya (ukujikeleza kokuxhumeka).

- Ukuqeda Umthelela womgwaqo omkhulu, Yehlisa i-nozzle yokumunca esigodini esiseduze kwephampu. Uma ingcindezi ikhuphuka ngokujwayelekile, ithrekhi kufanele isolwe futhi udinga ukubekwa uphawu emalungeni, noma ukukala amapayipi amakhulu noma ukufihla okukhona (amadolo akhona).

- Kwa- Bheka ukuqina Umgwaqo omkhulu, ngemuva kokucisha isiteshi, vele ulandele i-manometer isikhathi eside. Uma, ngama-cranes avaliwe, ingcindezi yehle - ukuvuza ohlelweni. Uma kungenjalo - uhlelo luvaliwe.

Ukulungiswa kwesiteshi sokupompa ngezandla zakho kuzokonga imali

- Isihlungi Esithwetshiwe kwipayipi noma Bheka i-valve . Zisuswa zihlanzekile, zihlola ukusebenza, zehlise futhi zichithe isivivinyo sokuqala.

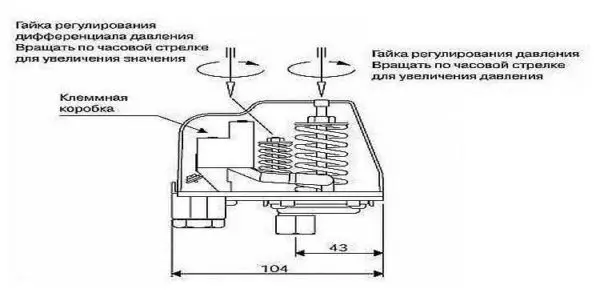

- Enye isizathu esingenzeka ukuthi iphampu ayikavaliwe - ingcindezi idlulisela ukungasebenzi kahle noma ukuvezwa ngokungafanele komkhawulo wepompo:

- Umkhawulo wengcindezi lapho ipampu kufanele icishwe kakhulu, ipompo ayikwazi ukuthola ingcindezi edingekayo. Bese niphatha Ukulungiswa kokutholwa kwengcindezi (Yehlisa umkhawulo wokuvalwa).

- Bheka Oxhumana Nabo - Zihlanze kusuka ku-sandpaper (emnyama emnyama) i-sandpaper emnyama enokusanhlamvu okuncane kakhulu (kungaba yifayela lezipikili).

- Susa ingcindezi idlulisela ukungasebenzi kahle kokuhlanza kwalo ( Susa usawoti ku-Springs Revolment futhi hlanza i-inlet nokuphuma). Vele nje, akunakwenzeka ukulimaza ulwelwesi. Uma kungasizi, ukushintshwa kuyadingeka.

Uma ukushintshwa kwengcindezi kungaphansi kakhulu kunengcindezi enkulu, engadala ipompo, futhi isikhathi esithile kwasebenza ngokujwayelekile, bese kumiswa, isizathu senye. Mhlawumbe ipompo Wasebenza i-impeller . Masinyane nje ngemuva kokuthenga, wabhekana, kodwa ohlelweni lokusebenza, impeller kanye "namandla akwanele manje." Ukulungiswa kwesiteshi sokupompa kuleli cala - ukufaka esikhundleni impepho yepompo noma ukuthengwa kweyunithi entsha.

Ukuvula noma ukufaka esikhundleni sempeller susa i-casing

Enye Isizathu Esingenzeka - Voltage ephansi kunethiwekhi . Mhlawumbe ipompo emathapheni anjalo namanje iyasebenza, futhi ukudluliswa kwengcindezi akusebenzi. Isixazululo - I-Voltage Stabilizer. Lezi yizizathu eziyinhloko zeqiniso lokuthi isiteshi sokupompa asicishiwe futhi asidayili ingcindezi. Kunenqwaba yazo ukuze isiteshi sokupompa silungiselele.

Ukulungiswa kwesiteshi sokupompa: kuvame ukuvula

Ukufakwa njalo kwephampu kanye nezikhathi ezimfishane zomsebenzi wazo kuholela ekugqokeni okusheshayo kwemishini, okuyinto engathandeki kakhulu. Ngoba ukulungiswa kwesiteshi sokupompa kufanele kwenziwe ngokushesha ngemuva kokuthi "uphawu" lutholwa. Lesi simo sivela ngenxa yezizathu ezilandelayo:

- I-Hydroaccumular ivolumu encane kakhulu . Lapho ukhetha isiteshi sokupompa isikhathi samakhaya namakamelo, i-hydroaccumularator ephansi yevolumu ivame ukuthathwa - amalitha angama-24 noma amalitha angama-32. Lokhu kuncane kakhulu, ngoba ukuhlinzekwa kwamanzi emabhodweni kungama-30-50% wevolumu yalo ephelele, okungukuthi, kuphela amalitha amanzi angama-7,2 angalayishwa kumathangi angama-24 wamalitha. Ngokwemvelo, leli gama lamanzi lichithwa ngokushesha okukhulu, kungani impompo iphenduka kaningi. Indlela yokwelashwa ukufaka enye i-hydroaccumulator eyengeziwe (ixhunyiwe ku-parallel kufakiwe).

- Imikhawulo eboniswe ngokungeyikho ngokutholwa kwengcindezi. Ukugwema lesi simo, kungenzeka ukwandisa i-delta (umehluko phakathi kwengcindezi yokunqamula nokuvula iphampu) futhi ngokulahlekelwa yilokhu, yenza umkhawulo wengcindezelo (ngempumelelo 1-1.5 ATM). Iphuzu elilodwa elibalulekile: ingcindezi lapho impompo iphenduka ibe ngu-0.2 ATM ngaphansi kunokucindezela ku-hydroaccumulator. Isiteshi sokupompa sivame ukuvula ngoba Ingcindezi ku-hydroaccumularator iphansi kunombukiso wepompo oveziwe . Ngoba:

- Bheka ingcindezi ku-hydroaccumulator . Ukuze wenze lokhu, susa ikhava yepulasitiki, ngaphansi kwengono (uhlobo lokuhamba ngebhayisikile). Sixhuma igeji yokucindezela, hlola ingcindezi. Imvamisa ngaphakathi kwe-1-1.5 ATM. Sifiphala noma siphonse (sikhwebule (ibhayisekili noma ipompo yezimoto, ifakwe ku-nippel efanayo ukuze ijwayelekile.

- Lungisa ukudluliswa kwengcindezi. Ifaka amapharamitha, kumele athole uhlelo olujwayelekile lokusebenza.

Lawula ingcindezi edluliselwe iziphethu ezimbili

- Ukushisa i-valve yokuhlola . Uma i-valve ingadlulisi amanzi, ishiya uhlelo, ingcindezi yehle, iphampu ivuliwe. Imvamisa yokufaka - cishe imizuzu eyi-10-20. Phuma - Bheka futhi uhlanze i-valve yokuhlola, uma kunesidingo, buyisela esikhundleni.

- Futhi imbangela kungenzeka Ukulimala kolwelwesi lwe-hydroaccumulator . Ngasikhathi sinye, ngaphezu kokufakwa kaningi kwephampu, amanzi futhi anikezwa amajezi: Lapho isiteshi sisebenza ngengcindezi ephezulu, lapho ingcindezi ixhunyaniswa ngokushesha. Kulokhu, kunezinketho ezimbili - Ulwelwesi noma ugoqwe okuyinto isiza kulokhu. Futhi kulokho, kwesinye isimo, kuzofanela unqamule i-hydroaccumulalator futhi ushintshe into enephutha.

- Imbangela yayo eyodwa yokupompa imvamisa yepompo nokuhanjiswa kwamanzi ngama-jumps - aphukile Spool ngaphezulu kwe-hydroacumulator . Ukuyifaka esikhundleni, kuzodingeka ususe i-hydroaccumulalator, ususe ulwelwesi bese ufaka khona ingono.

Manje uyazi ukuthi kungani isiteshi samaphampu kwesinye isikhathi sivulwa nokuthi senzeni ngakho. Kukhona ngendlela, enye imbangela yesizathu - Ngokusebenzisa umfundisi Noma ukuxhumeka okuthile, ngakho-ke uma konke okungenhla kungasebenzi ecaleni lakho - Bheka ukuthi akuqhubeki kwenye indawo.

Umoya emanzini

Inani elincane lomoya emanzini lihlala likhona, kepha lapho i-crane iqala 'ukukhafulela,' kusho ukuthi kukhona okusebenza ngokungalungile. Kungaba nezizathu eziningana nazo:

- Isibuko samanzi sehlisiwe Futhi iphampu idonsa amanzi ngesigamu emoyeni. Isixazululo kuleli cala silula - ukwehlisa i-nozzle noma ipompo ngokwayo ngezansi.

- Ipayipi seliphenduke -Ngehlazo Futhi umoya ungena ekuxhumekeni okukodwa noma okuningi. Ukuqedwa - hlola amakhompiyutha nokubuyiselwa kokuqina.

Enye yezizathu zenani elikhulu lomoya emanzini ukulahleka kokuqina kwepayipi lokumunca

Isiteshi sokupompa asivuli

Into yokuqala ukubheka - Voltage. Amaphampu afunwa kakhulu kumandla kagesi, ngokuncishiswa nje awasebenzi. Uma konke kuhamba kahle ngogesi, udaba lubi kakhulu - kungenzeka ukuthi imoto inephutha. Kulokhu, isiteshi senziwa esikhungweni senkonzo noma sabeka iphampu entsha.

Uma uhlelo lungasebenzi - udinga ukubheka ingxenye kagesi

Ukusuka kwezinye izizathu - ukungasebenzi kahle kwemfoloko / izisekelo, intambo iyadonswa, oxhumana nabo bashiswa / oxhumana nabo endaweni yokunamathiselwa kwekhabethe likagesi. Lokhu yilokho ongakuhlola nokukuqeda. Ochwepheshe benziwa ukulungisa okukhulu kwengxenye kagesi yesiteshi sokupompa.

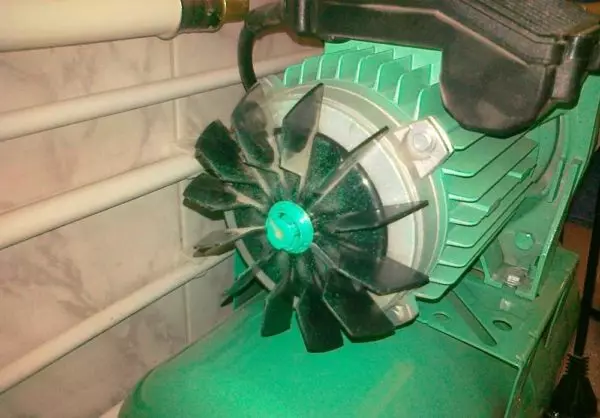

I-motor iyaluza, kepha ayipholisi amanzi (umsizi akazizungezi)

Ukungasebenzi kahle okunjalo kungabangelwa I-Low Voltage Online . Yibheke ukuthi konke kujwayelekile, iya ngaphezulu. Udinga ukubheka hhayi ngokweqile I-condenser ebhlokini elibulalayo . Sithatha umhloli, hlola, uma kunesidingo, ushintsho. Uma lesi akusona isizathu, iya engxenyeni yemishini.

Okokuqala kufanele ubheke ukuthi ngabe kukhona amanzi emthonjeni noma emthonjeni. Okulandelayo hlola isihlungi bese uhlola i-valve. Mhlawumbe bashaya noma benephutha. Hlanza, hlola ukusebenza, shiya ipayipi endaweni, qala isiteshi sokupompa futhi.

Ihlola i-impeller - lokhu kungukulungiswa okunzima kwesiteshi sokupompa

Uma kungazange kusize, impeller eshisiwe. Bese uzama ngesandla i-shaft. Kwesinye isikhathi ngemuva kokuphumula isikhathi eside, "imigqomo" - yeqa usawoti futhi ayikwazi ukunyakaza. Uma amabala engasebenzi ngezandla, kungenzeka ukuthi impeller igwazwe. Lapho-ke ukulungiswa kwesiteshi sokupompa kuyaqhubeka nokususa ukuvikela okuvikelayo futhi uvule i-impeller.

Ezinye izinhlobo zomsebenzi wokulungisa

Ezinye izenzo zokulungisa isiteshi sokupompa ziqondakala ngendlela eqondakalayo. Isibonelo, hlanza i-valve yesheke noma isihlungi ngeke kube nzima, kepha ukufaka esikhundleni se-membrane noma iparele ku-hydroaccumulator kungaba nzima ngaphandle kokulungiselela.Ukufakwa esikhundleni kwe- "pears" hydroaccumulator

Isibonakaliso sokuqala sokuthi ulwelwesi lwalonakaliswa khona - ukufakwa kwesikhashana kwesiteshi esifushane nesifushane esiteshini sokumpompa, namanzi anikezwa amajezi: bese kuba nengcindezi eqinile, bese kuba nobuthakathaka. Ukuze uqiniseke ukuthi ulwelwesi luwukuthi, susa i-cap e-nippele. Uma kungekho moya ngaphandle kwayo, kepha amanzi, kwaqubuka ulwelwesi.

Idivayisi ye-membrane tamp ilusizo lapho ungena esikhundleni samapheya

Ukuqala ukulungisa i-hydroaccumulalator, nqamula uhlelo lwamandla, setha kabusha ingcindezi - vula ompompi bese ulinda kuze kube yilapho imivimbo kamanzi. Ngemuva kwalokho, ingacishwa.

Okulandelayo, inqubo enjalo:

- Yenza buthaka ukuqina kwe-flange phansi kwethangi. Silinda kuze kube yilapho izithungo zamanzi.

- Sisusa yonke amabhulokhi, susa i-flange.

- Uma ithangi lisuka kumalitha ayi-100 nokuningi, esiqongweni sethangi esibonisa umlungu we-membrane.

- Sikhipha ulwelwesi ngomgodi ezansi kwethangi.

- Sigeza ithangi - imvamisa inokuduka okuningi okugqwala.

- Ulwelwesi olusha kufanele lufane kanye nokonakala. Faka okufanele kuyo, okuyingxenye engenhla enamathiselwe ezindlini (spin).

- Faka ulwelwesi lungene ethangini le-hydroaccumulator.

- Uma ukhona, setha i-nati yomnikazi we-membrane phezulu. Ngosayizi omkhulu wethangi, ngeke uthole isandla sakho. Ungabopha umnikazi wentambo ngakho-ke faka into esendaweni ngokuhlikihla nati.

- Selulula intamo bese sicindezela i-flange, faka ama-bolts, siwajezise ngokungaguquki ibe izinguquko eziningana.

- Xhuma ohlelweni bese uhlola umsebenzi.

Ukufaka esikhundleni se-pump station membrane sekuqediwe. Icala lilula, kepha ama-nuances adinga ukwazi.

Isihloko ngesihloko: Ukuhlelwa okufanele kahle nge-timer