In order for the "good" in the garage, it is not difficult to move in some way to organize its storage. The most comfortable racks for the garage. In the presence of sufficient space, they can be made on the entire wall or even a few walls. If there is no place at the bottom, you will have to move upstairs - make shelves under the ceiling. Not the best option, but sometimes the only one. And yet racks in the garage standing on the floor are safer, especially if they are securely attached to the wall (in order to avoid unpleasant situations).

What rack is better: welded or bolted

The racks for the garage are made of wood and metal. Wooden most unimprovable - on nails and self-drawing. They are usually installed stationary, fixed to the wall. Metal racks can be cooked. Then they are intimidrate. There are racks on bolted connections. These designs are mobile, if necessary, if necessary. Their disadvantage is insufficient stiffness, since there is always some backlash in such a connection. To make the design more stable, it is fixed to the walls. To do this, the metal plates with a hole can be welded to extreme racks (attaching bolts). In this hole, drive the crutch (a slightly smaller diameter in the wall is pre-installed in the wall).

One of the options - the frame from the profile pipe and plywood shelves

And welded, and bolted racks for the garage are serviced, but more often there are welded structures. The collapsible option is chosen in two cases. The first - it will be possible to move to another garage and all the equipment will need to be transported, and weigh the design hundreds of kilograms, so it is entirely to move it problematic. The second is no possibility or desire to use welding (if the racks for the garage do it yourself). The rest usually prefer the welded - they are more stable and in the presence of the experience of welding going faster.

Metal racks from perforated corners are still on sale. They are also mobile and can understand, but they are connected with hooks (on crossbar) and grooves (on racks). Such storage systems are convenient - you can rearrange the shelves to the desired height. Their minus is expensive.

Designs and sizes

Constructive racks for the garage consist of racks, crossbars and shelves. Sometimes, to increase stiffness, there are still transverse tightening on the back of the back - two steel strips, welded / screwed to extreme racks diagonally. They compensate for lateral loads increasing public stability and reliability.

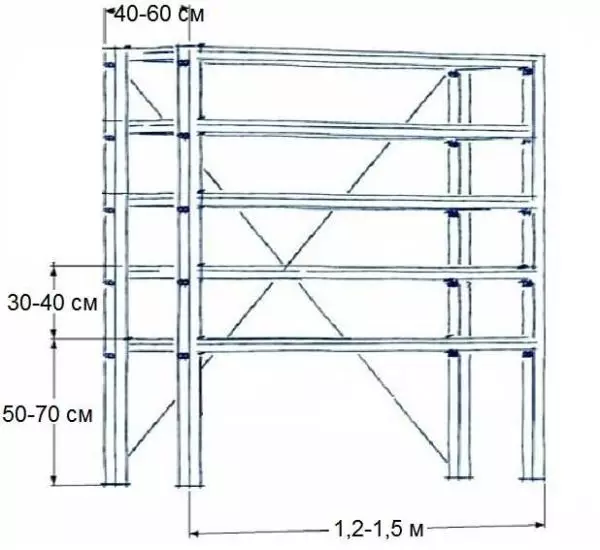

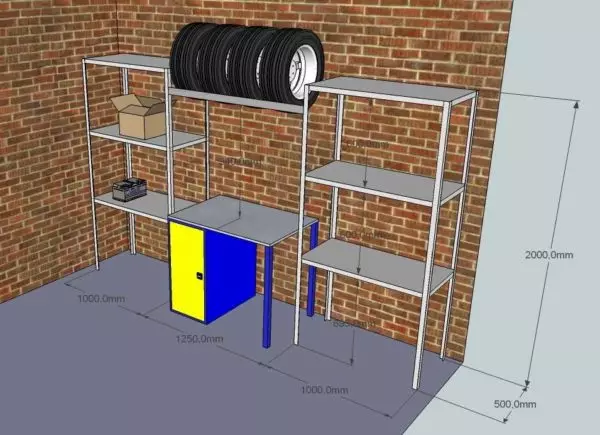

Racks in the garage can be made by this drawing (sizes are approximate)

Dimensions - the height and depth of the shelves - are selected virtually arbitrarily - depending on what you intend to store. The only thing to pick up neatly - the length of the span is the distance between the racks in one section. It depends on the stiffness of the material that you decide to use: the shelves even at full load should not be fed. For heavy things / items, the length of the span is about 1.5 meters, if the load is not too big, the distance can be increased to 2 meters, but it is no longer possible to do more. If you need a rack for a garage of greater length, they put an intermediate rack, the distance between which can still be more than 2 meters.

Article on the topic: How to attach velcro to the eternity: Popular ideas

A few words about the height of the shelves in the rack. The lowest shelf can be raised from the floor level by 50-70 cm (even more if desired). This usually put the most difficult items. The remaining shelves can be made at different heights, 30 cm is inconvenient and impractical. In general, a 1.5 liter plastic bottle should become optimally on the shelf, and this is 35-37 cm. Such a distance is convenient for use.

What makes

As already said, racks for the garage are made of wood and metal. Wood easier by weight, with wood it is easier to work, but they are withstanding not such heavy loads. Metal is heavier (heavier is heavier), but they can be put on both an elephant.

There is another question price. Metal rolls are not at all supreme. If you buy everything in the market or in the store, at the price of you one rack (along with consumables) will cost almost the same amount as ready. The only real way to save is to buy metal on metal supplies with whole whips (there are 6 m and 12 m), and then cut into segments of the desired length. Cutting can be right on the database, you will have to additionally pay for services, but the amounts are very small. In this case, you will be able to reduce costs by about 20-30%.

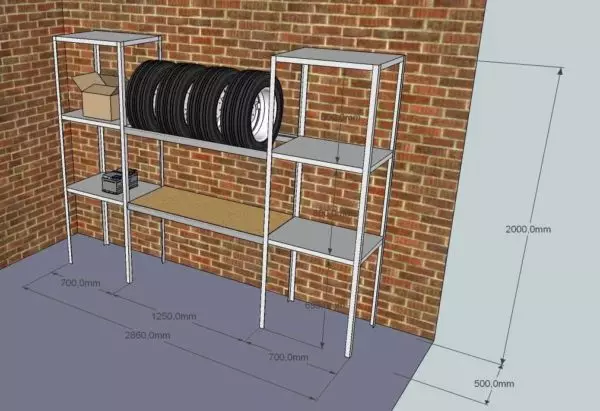

One of the layout options

Timber in comparison with the metal are less. But do not think that costs will be small: you will have to buy varietal wood without bitch, and this is the class "elite" or "premium" with the corresponding price tag. So it will not work very cheaply.

From wood

The operating conditions in the garage are far from the best - elevated humidity, frost, alternate size / freezing, sometimes heat. Not very good for wood. Therefore, all the material before work must be treated with antibacterial and protective compositions. Take products for wood for outdoor work, as the conditions in the unheated garage are more similar to them. You can pick up such a means that simultaneously ties the treated surface and your product can not be painted. After processing, the materials are dried and only after that begin work.

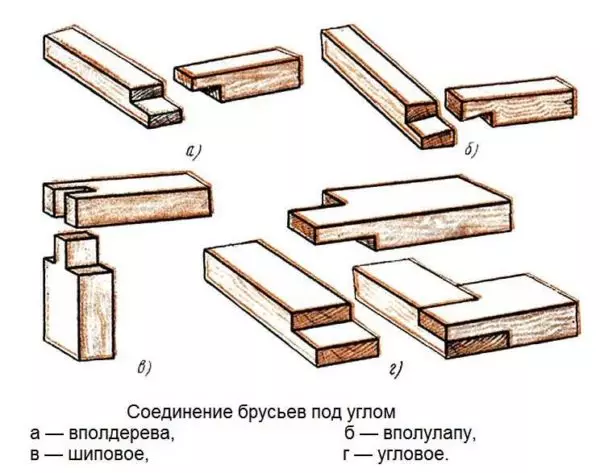

How to connect Brucki

When connecting parts of a wooden shelving, you can use standard methods for carpenters - in a quarter or in full. If this is difficult for you, you can navigate and jack, and to enhance the compounds to use metal corners and / or overhead plates.

Another time: to connect better on the nails, and not on the self-tapping screw. It turns out more steadily, less compound is "clench." If you have chosen the option with the amplification of the plates, they can be attached to the screws.

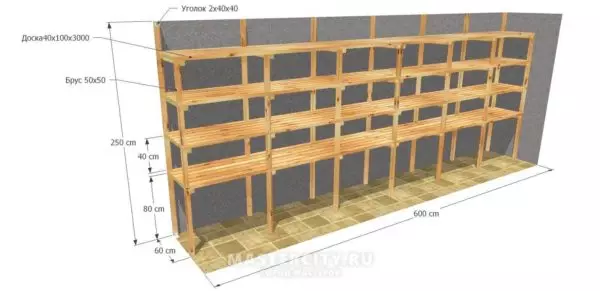

Wooden garage rack

Now in size: for racks usually use a 50 * 50 mm for racks, the same bar can be used for the crossbar or slightly thinner - 50 * 30 mm. Flooring make from:

- boards with a thickness of at least 21 mm;

- moisture-resistant plywood thickness from 10 mm;

- laminated chipboard;

- OSP.

The cheapest is the board and plywood. Laminated chipboard is significantly more expensive, but it is not necessary to paint, and this is a good plus. In order not to spend a lot, you can take the first and last sheets in the base - they scratched and go much cheaper.

Article on the topic: How to choose closers for doors: species, characteristics

Wooden rack in the garage - drawing with dimensions

Another moment: the shelves from the chipboard remains open side cut. If it is not necessary to process it, with increasing moisture, the chips will swell, the shelf will become brewing. So that this does not happen, wake the edges with silicone. With such a treatment, nothing with chipboard will not happen.

Metal

If you decide to make metal racks for the garage, the choice of materials is wider - there are two options for metal, plus standard solutions for storage rooms (perforated corners). You can also use metal parts intended for other purposes - for example, steel cable racks or cable channels are used, which are used in connection.

Channels and shelves - convenient and not very expensive

So what makes the frame of a metal rack in the garage:

- Metal corner with metal thickness from 3-4 mm. Width of the shelf corner - 25-45 cm - depending on the planned loads. Durable, but metal material, weighs a lot, it is expensive.

- Profile tube (rectangular in cross section). With less solid componence (the wall thickness is less), compared with the metal corner has the best characteristics of elasticity (it is difficult to bend), more resistant torsion. Approximate dimensions for racks 50 * 50 mm or 40 * 40 mm, on the crossbar 50 * 25 mm or 40 * 25 mm, respectively.

- Racks make out of proftrub, and crossbars from the corner. Metal thickness is 2-3 mm, the width of the shelf is 25 mm and more. Deploy the corner so that the stacked flooring was like in the "nest".

Look carefully how the corners are located

The flooring on the shelves are made from the same materials as for a wooden shelving (board, plywood, OSP, chipboard), only sometimes non-standard options are added, which with a wooden frame is used dramatically due to high mass - sheet metal.

The board is optimal for most regions - a reliable, not very expensive material. You need to take sex, without bitch (with a minimum of bitch) with a thickness of 21 mm. Treat antiseptics, then paint.

Plus metal shelves - high reliability at low thickness, minuses - price, weight and "volume". They also need to be painted, only first clean from rust, then walk the rust converter and the soil, then dye and preferably in two layers. Also, by the way, it is necessary to process and metal framework. Then the rack in the garage will not rust.

Features of the assembly of metal racks

Metal racks can be welded or collected on the bolts. With welding usually no questions arise. If you are using a corner, you can connect the Vansel - a difference of 3-5 mm when laying the shelves is invisible. If you wish, you can cut more superfluous in one of the shelves, cook the jack, but the trimming takes a lot of time, and you will not see much difference.

How to cut corners for smooth connections

With the assembly of the frame for the rack on the bolts, the order of this: first the sides of the sides and shelves are collected separately, then they are twisted together. For each compound, it is preferably at least two bolts - for greater stiffness (less peeling).

Article on the topic: We make a podium for the shower cabin with their own hands

If they are going to make racks for the garage from the profile pipe, the order of operation is different. First collect sidewalls, short cross-shirts are fixed. Two rectangles with crossbars are obtained. Then they are connected by crossings.

Methods of bolted compound of profile pipes

How can I make connections look in the photo. In one case, the welding is still needed - to privar "Note", in the other you can do without it - cut the "ears", bend and cling for them.

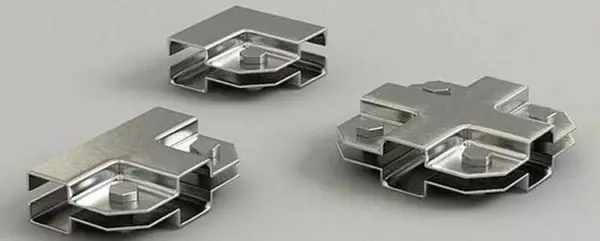

There is another way - special crab systems. These are metal plates with molded recesses. Pipes are laid in the grooves, then two plates are tightened by bolts.

Crab Systems for Profile Pipes

Very long loads such a connection is unlikely to endure, but there are indisputable plus - it is not necessary to drill a bunch of holes in the metal. In the profiled pipe, this is definitely easier than in a thick-walled corner, but still takes a lot of time and effort.

By the way, the bolts are used M8 or M6, respectively, they require large holes. It is easier to first drill a thin drill, then expand to the desired size to thick. But even with this order, you need a solid amount of drills. So that they overheat less and less closely, next to the jar with water, lower the drill periodically.

Layout, schemes, drawings, ideas

In the garage, not only the rack is needed, but you still need a workbench and a stand for a hand tool - all sorts of keys and other smallers, which is much and invent some kind of certain convenient storage location.

The workbench can be made in the center of the rack. It is convenient - everything you need will be at hand, you do not have to constantly go to the shelves.

Garage racks with workbench are comfortable

The workbench can be part of the system, and you can make two separate modules, between which you set the desired table. If this location does not like it, it will be possible to change the configuration - even though put an angle.

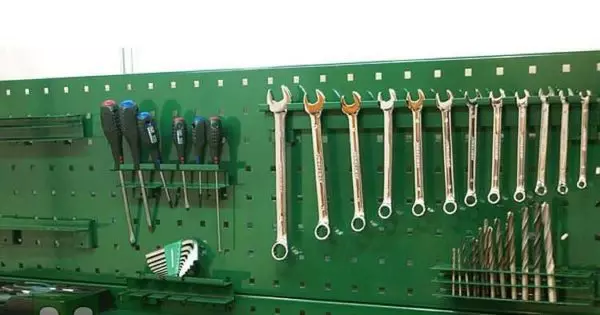

As for the bench for the tool. There is a factory option - a perforated metal sheet with holders hanging on it. The idea is very good with the exception of the price.

Conveniently))

As usual, there are several homemade (what kind of garage without them) on the same topic. Ideas are easy to perform, maybe not so elegant, but comfortable:

- On the boards, sheet chipboard, plywood, fill nails for each tool. In order not to be confused where to hang - bother the tool in place and paint some color.

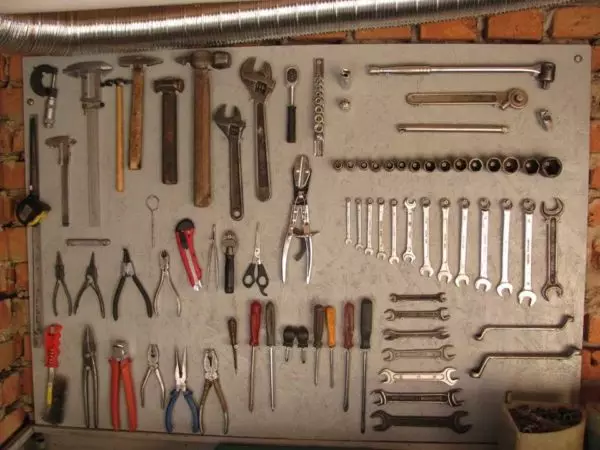

Everything is in order and in place

- For more heavy equipment - large keys, etc. You can use the grid on which the hooks are screwed from the top. Grid to nail on the wall.

Option for heavier and bulky tools

- Make a bar with holes cut in it in which the tools are lowered.

This booth for the tool makes it yourself quite simple

And if you wish, all this can be put on the wheels - make a stand for a mobile tool. This is the case if in the warm season you prefer to work with the car on the street.

You can easily roll back where

Well, for inspiration ... so that all the tools are in place at all))

Full order))