A constant pressure in the water supply system of a private house is usually created using a pumping station. It is clear that it is better if it works without problems, but breakdowns occur periodically. To quickly restore water supply and save on services, you can repair the pumping station with your own hands. Most of the breakdown can be eliminated on their own - nothing is supervised to do.

Composition of the pumping station and purpose of parts

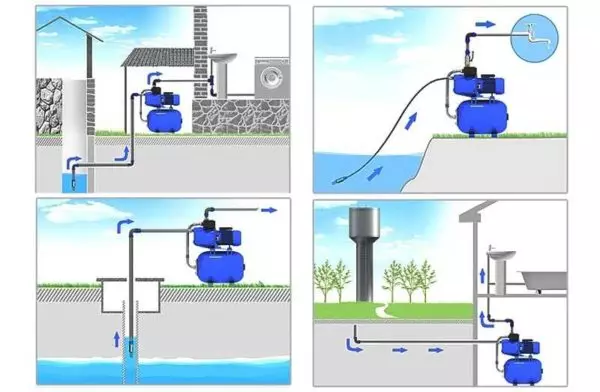

The pumping station is a set of separate devices interconnected. To understand how to repair a pumping station, you need to know from what it consists, how each of the parts works. Then the faults are eliminating easier. Composition of the pumping station:

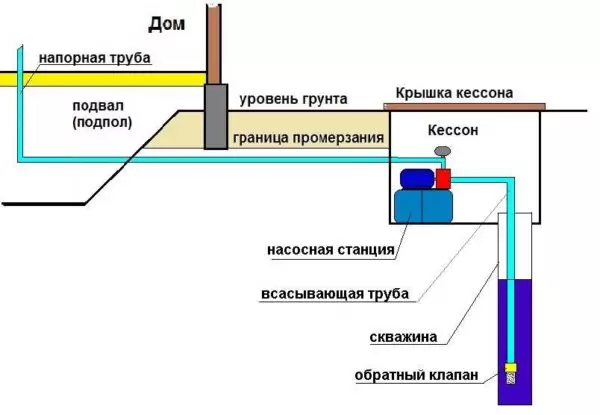

- Submersible or surface type pump. Swits water from a well or well, maintains stable pressure in the system. The house is connected with the help of pipes.

- On the pipeline is required to install the check valve. It does not give water when the pump is disconnected from the pipes back to the well or well. It is usually installed at the end of the pipe, lowered into the water.

What is the pumping station

- Hydroaccumulator or membrane tank. Metal hermetic container, divided into two halves of an elastic membrane. In one, the air (inert gas) is under pressure, to another, before creating a certain pressure, water pumps out. The hydroaccumulator is necessary to reduce the number of inclusions of the pump, extending its service life. Creates and maintains the required pressure in the system and a small reserve supply of water in case of the inoperability of the station.

- Control unit and pumping station control. This is usually a pressure gauge and pressure switch, is installed between the pump and the hydroaccumulator. Manometer is a controller that allows you to estimate the pressure in the system. Pressure switch controls the operation of the pump - gives the command to turn on and off. The inclusion of the pump occurs when the lower pressure threshold is reached in the system (usually 1-1.6 atm), shutdown when the upper threshold is reached (for single-storey buildings 2.6-3 atm).

Each of the parts is responsible for a specific parameter, but one fault type can be caused by the failure of various devices.

Principle of operation of the pumping station

Now let's look at how all these devices work. When you first start the system, the pump pumped into the hydroaccumulator water to those prospecting until the pressure in it (and in the system) is equal to the upper threshold on the pressure relay. There is no water consumption yet, the pressure is stable, the pump is turned off.

Each of the parts does its work.

Somewhere opened the crane, the water was lowered, etc. For a while, water comes from the hydroaccumulator. When its number decreases so much that the pressure in the hydroaccumulator drops below the threshold, the pressure switch is triggered and includes a pump that pumps water again. It turns off again the pressure relay when the upper threshold is reached - the trip threshold.

If there is a permanent consumption of water (bath, watering the garden / garden is turned on) the pump runs for a long time: while the desired pressure is not created in the hydroaccumulator. This periodically occurs even with all the cranes opened, since the pump gives water less than it follows from all the disarm points. After the consumption stopped, the station still works for a while, creating the required reserve in the gyroaccumulator, then it turns off and turns on after the water consumption appears again.

Problems and malfunctions of pumping stations and their correction

All pumping stations consist of the same parts and the breakdowns of them are mainly typical. There is no difference, the equipment is Grundfos, Jumbo, Alco or any other firms. Diseases and their treatment is the same. The difference is how often these faults happen, but their list and causes are usually identical.

Pumping options for pumping station

The pumping station is not turned off (no pressure is dialing)

Sometimes you notice that the pump works for a long time and will not turn off. If you look at the pressure gauge, it can be seen that the pumping station does not gain pressure. In this case, the repair of a pumping station is a long-term business - you have to overlook a large number of reasons:

- In a well or well no water . If this is true, it is called such a situation "dry running" and threatens the fact that the motor will be overgrown. Water that pumps pump is used to cool the motor. No water, it overheats and burns. To protect against such a situation, special protection is needed: water level sensors (float and electric).

- A large resistance of the suction highway (a large length with a small diameter of pipes) or air seats (spinning of the connection).

- To eliminate The impact of the highway, Lower the suction nozzle in a barrel next to the pump. If the pressure rises normally, the track is to blame and you need to be sealed at the joints, or it is to lay thicker pipes or hide the existing (less knees and connections).

- To Check tightness Suction highway, after turning off the station, just follow the manometer for a long time. If, with closed cranes, the pressure drops - leakage in the system. If not - the system is sealed.

Repair of the pumping station with your own hands will save money

- Scored filter on the pipe or Check valve . They are removed cleanly, they check the performance, lowering and spend a test start.

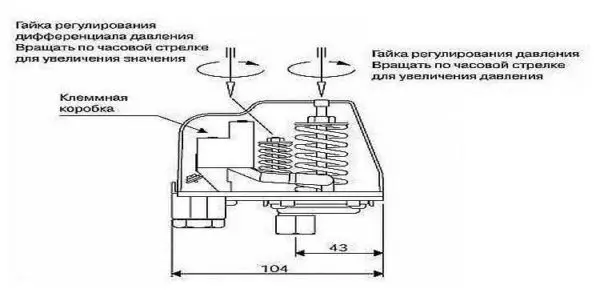

- Another possible reason that the pump is not turned off - a pressure relay malfunction or incorrectly exposed pump shutdown limit:

- The pressure limit in which the pump must turn off too high, the pump is simply not able to catch up the required pressure. Then conduct Adjustment of pressure relay (Reduce shutdown limit).

- Check relay contacts - Clean them from scale (dark dark) sandpaper with a very thin grain (can be a nail file).

- Eliminate the pressure relay malfunction of the cleaner of it ( remove salt on springs adjustment and clean the inlet and outlet). Just neatly, it is impossible to damage the membrane. If it does not help, replacement is required.

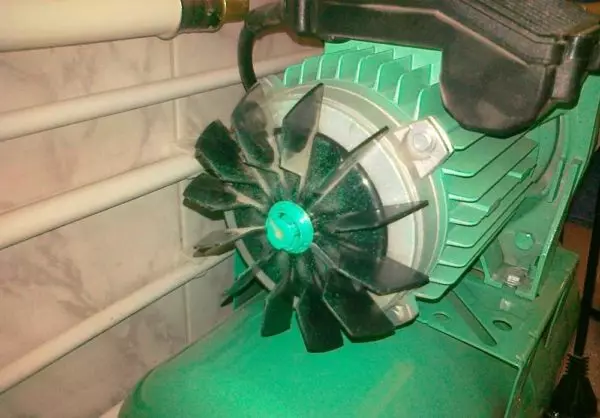

If the pressure switch is not much lower than the maximum pressure, which can create a pump, and for some time it worked normally, and then it stopped, the reason in the other. Perhaps the pump Worked the impeller . Immediately after the purchase, he coped, but in the process of operation, the impeller and the "strength is not enough now." Repair of the pumping station in this case - replacing the impeller of the pump or the purchase of a new unit.

To unlock or replace the impeller remove the casing

Another possible reason - Low voltage in the network . Maybe the pump at such a voltage still works, and the pressure relay does not work. Solution - voltage stabilizer. These are the main reasons for the fact that the pumping station is not turned off and does not dial pressure. There are quite a lot of them so that the pumping station repair can delay.

Repair of the pumping station: often turn on

Frequent inclusions of the pump and the short intervals of its work lead to the rapid wear of the equipment, which is very undesirable. Because the repair of the pumping station must be carried out immediately after the "symptom" is detected. This situation arises for the following reasons:

- Hydroaccumulator too small volume . When choosing a pumping station for home and cottages, a low-volume hydroaccumulator is often taken - 24 liters or 32 liters. This is very small, since the supply of water in such pots is only 30-50% of its total volume, that is, only 7-12 liters of water can be loaded into the tank 24 liters. Naturally, this volume of water is spent very quickly, why the pump turns on frequently. The treatment method is to install an additional hydroaccumulator (it is connected in parallel to the already installed).

- Incorrectly exhibited pressure relay limits. To avoid this situation, it is possible to increase the delta (the difference between the pressure for disconnecting and turning on the pump) and at the expense of this, make the pressure threshold (optimally 1-1.5 atm). One important point: Pressure in which the pump turns on to be 0.2 atm below than the pressure in the hydroaccumulator. The pumping station can often turn on just because Pressure in the hydroaccumulator is lower than the exposed Pump Turning Threshold . Because:

- Check the pressure in the hydroaccumulator . To do this, remove the plastic cover, under it nipple (type of cycling). We connect the pressure gauge, check the pressure. It is usually within 1-1.5 atm. We bleak or pumped up (bicycle or automotive pump, screwed to the same nippel so that it is normal.

- Adjust the pressure relay. Features the parameters, must receive a normally working system.

Regulate the pressure relay with two springs

- Burning the check valve . If the valve does not overlap water, it leaves the system, the pressure drops, the pump is turned on. Inclusion frequency - about 10-20 minutes. Exit - check and clean the check valve, if necessary, replace.

- Also the cause may be Damage to the membrane of the hydroaccumulator . At the same time, in addition to frequent inclusion of the pump, water is also supplied to jerks: when the station is working with high pressure, when the pressure is disconnected immediately falls. In this case, there are two options - The membrane or folded which crepts it to the case. And in that, in another case, you will have to disconnect the hydroaccumulator and change the faulty item.

- Its one cause of frequent pumping of the pump and water supply with jumps - broken Spool in the top of the hydroacumulator . To replace it, you will have to remove the hydroaccumulator, remove the membrane and replace nipple.

Now you know why the pump station is often turned on and what to do about it. There is by the way, another possible reason - Through the lecturer Or some connection, so if all of the above does not apply to your case - check whether it does not flow somewhere.

Air in water

A small amount of air in the water is always present, but when the crane begins to "spit," it means that something works incorrectly. There may be several reasons too:

- Water mirror lowered And the pump pulls water in half with air. The solution in this case is simple - to lower the nozzle or the pump itself below.

- Pipeline has become Negroetic And the air enters one or more connections. Elimination - Check compounds and tightness restoration.

One of the reasons for a large amount of air in water is the loss of tightness on the suction pipeline

The pumping station does not turn on

The first thing is to check - voltage. Pumps are very demanding on voltage, with a reduced simply do not work. If everything is fine with the voltage, the matter is worse - most likely the motor is faulty. In this case, the station is carried to the service center or put a new pump.

If the system does not work - you need to check the electrical part

From other reasons - the malfunction of the fork / sockets, the cord is pulled, the contacts were burned / oxidized in the place of attachment of the electric cabin to the motor. This is what you can check and eliminate yourself. Experts are carried out more serious repair of the electrical part of the pumping station.

Motor is buzzing, but does not pump water (the impeller does not rotate)

Such a malfunction may be caused Low voltage online . Check it if everything is normal, go further. Need to check not overwhelming Condenser in the terminal block . We take the tester, check, if necessary, change. If this is not the reason, go to the mechanical part.

First you should check whether there is water in a well or a well. Next check the filter and check valve. Maybe they beat or faulty. Clean, check the performance, omit the pipeline to the place, start the pumping station again.

Checking the impeller - this is a serious repair of the pumping station

If it did not help, the impeller jambled. Then try manually turn the shaft. Sometimes after a long downtime, it "bins" - overlaps the salts and can not move. If the blades did not work with the hands, it is possible that the impeller jammed. Then the repair of the pumping station continue to remove the protective casing and unlock the impeller.

Some types of repair work

Some actions to repair the pumping station are intuitively understandable. For example, clean the check valve or the filter will not be difficult, but to replace the membrane or pear in the hydroaccumulator can be difficult without preparation.Replacement of "Pears" Hydroaccumulator

The first sign that the membrane was damaged - frequent and short-term inclusions of the pumping station, and the water is served by jerks: then a strong pressure, then weak. To make sure that the membrane is, remove the cap on the nippele. If there is no air out of it, but water, then the membrane broke out.

The membrane tank device is useful when replacing pears

To start repairing the hydroaccumulator, disconnect the power system, reset the pressure - open the taps and wait until the water strokes. After that, it can be turned off.

Next, the procedure for such:

- Weaken the fastening of the flange at the bottom of the tank. We wait until the water stalks.

- We unscrew all the bolts, remove the flange.

- If the tank is from 100 liters and more, in the top of the tank we unscrew the nut membrane holder.

- We take out the membrane through the hole at the bottom of the tank.

- We wash the tank - it usually has a lot of rusty sediment.

- The new membrane should be exactly the same as damaged. Insert the fitting into it, which the upper part is attached to the housing (spin).

- Install the membrane into the tank of the hydroaccumulator.

- If you are, set the nut of the membrane holder at the top. With a large size of the tank, you will not get your hand. You can bind the holder to the rope and so install the item in place by screwing the nut.

- We stretch the neck and press the flange, install the bolts, consistently twisting them into several revolutions.

- Connect to the system and check the work.

Replacing the pump station membrane is completed. The case is simple, but the nuances need to know.

Article on the topic: Proper setting Outlet with a timer